Prediction method of abrasiveness of tunnel boring machine TBM cuter

A prediction method and abrasiveness technology, which is applied in the direction of testing wear resistance, etc., can solve the problem of not being able to accurately predict the wear of the hob body, and achieve the effect of reducing maintenance and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment, the embodiment of the present invention is described further;

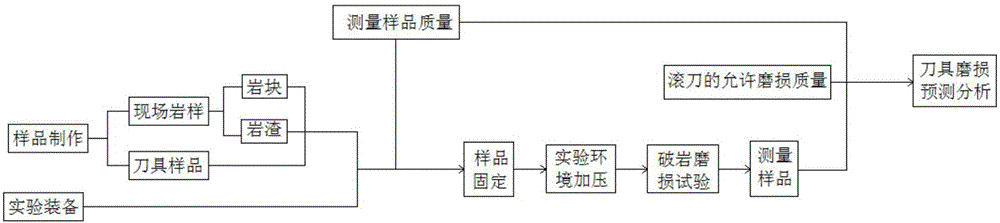

[0030] A kind of shield TBM hob abrasiveness prediction method, concrete steps are as follows (hob TBM abrasiveness prediction experimental method flow chart is as follows figure 1 shown):

[0031] 1) Hob sample making

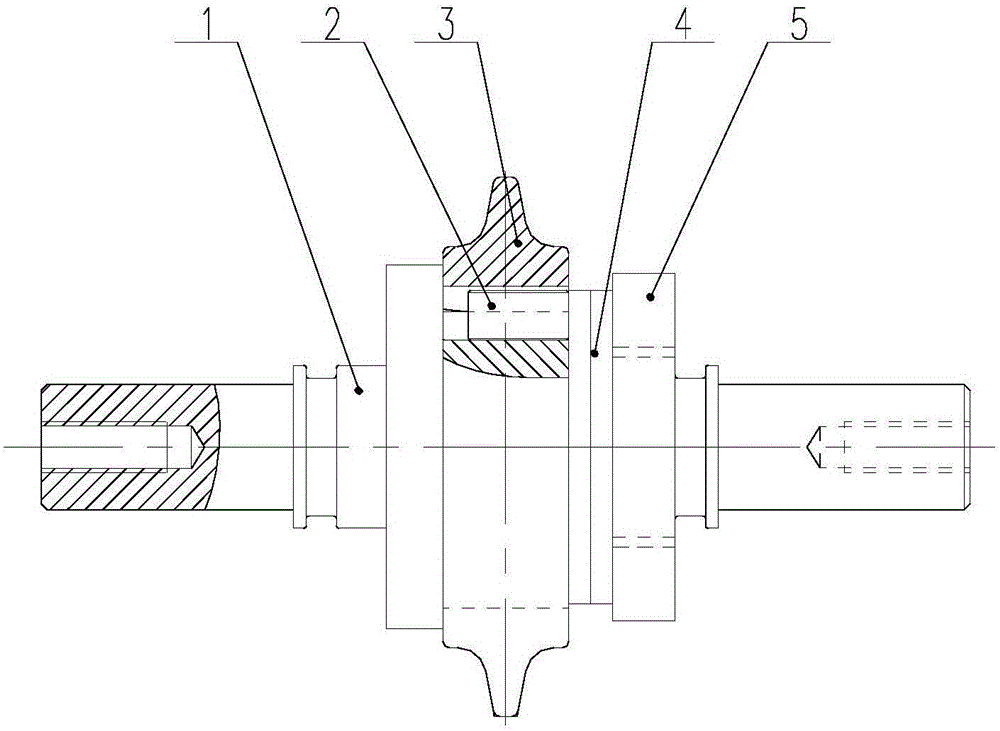

[0032] The hobs designed according to the site provided by different suppliers are based on the size of the hob cutter ring used on site, and the size of the cutter ring of the hob sample is reduced by 10 times. The other dimensions of the hob sample are based on the size of the cutter ring. , to carry out the design, the schematic diagram of the hob sample used in the experiment; as figure 2 As shown, ( figure 2 Middle, 1. Cutter shaft; 2. Flat key; 3. Cutter ring; 4. Washer; 5. Lock nut;)

[0033] Design 6 samples for each type of hob;

[0034] 2) Rock sample making

[0035] After the on-site physical explorat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com