A Titanium Tube Outboard Cooler Resistant to Seawater Corrosion

A seawater-resistant, external cooling technology, applied in indirect heat exchangers, heat exchanger types, fixed tubular conduit assemblies, etc., can solve the problems of accelerated cooler corrosion, heat-resistant biosorption, and unfavorable cooler heat dissipation, etc. Achieve the effect of reducing weight, reducing possibility, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

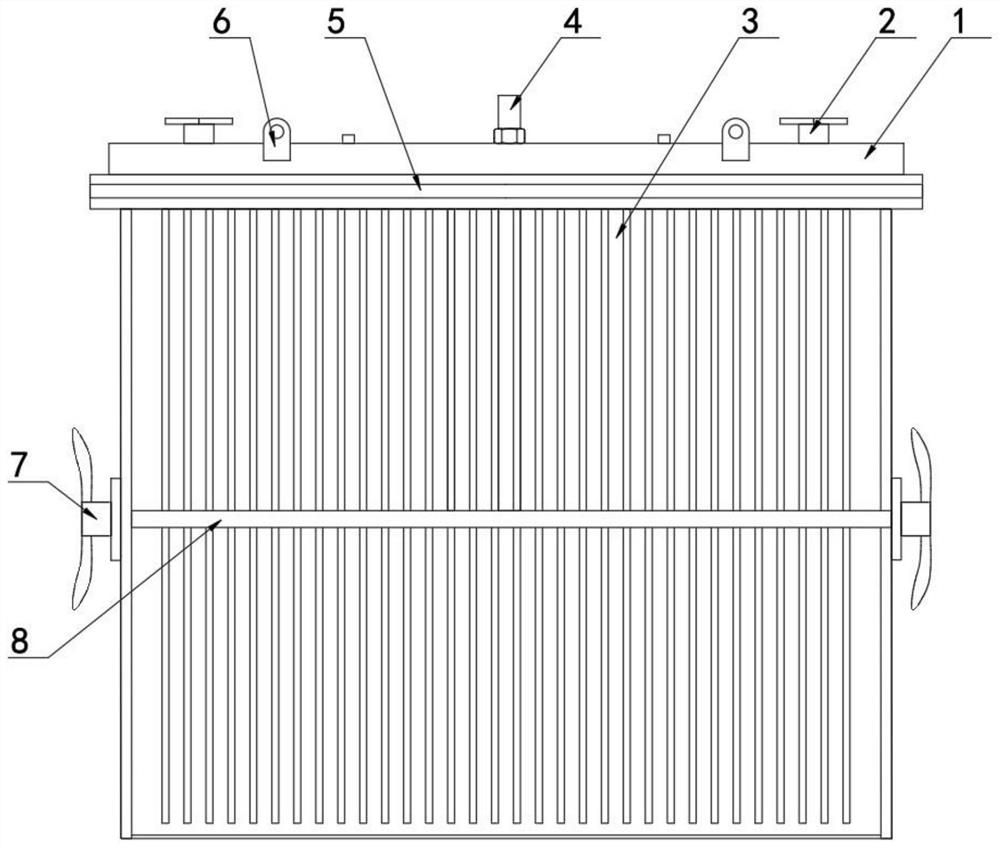

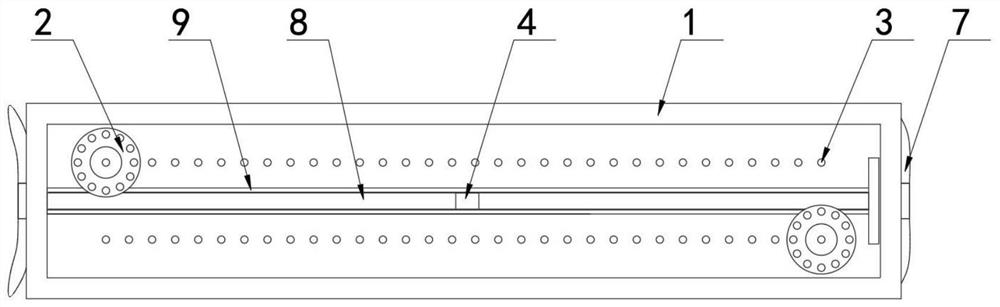

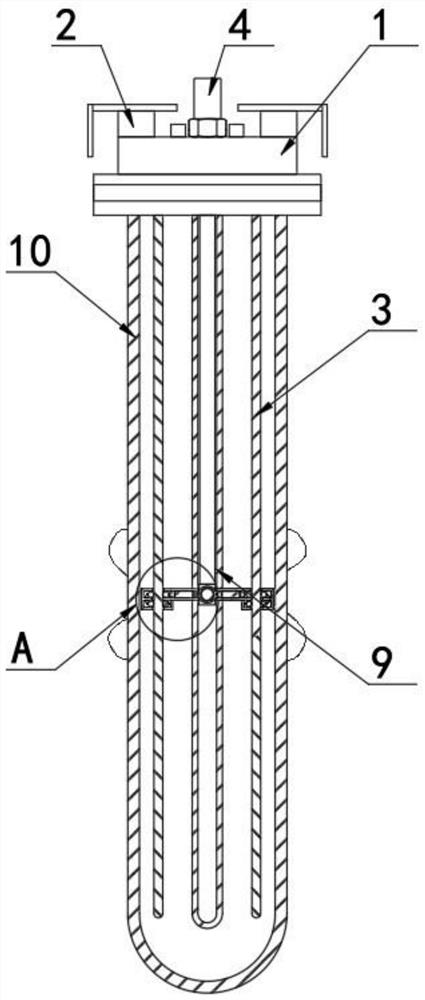

[0025] Embodiment one, with reference to Figure 1-4 , a seawater corrosion-resistant titanium tube outboard cooler, including an end cover 1 and a tube plate 10 fixedly connected to the bottom of the end cover 1, the inner cavity of the tube plate 10 is provided with a cooling tube 3, and the two sides of the upper end surface of the end cover 1 are connected respectively There are two flanges 2, and the two flanges 2 are connected with the cooling pipe 3, the center of the lower end surface of the end cover 1 is provided with a limit groove 9, and the inner cavity of the limit groove 9 is slidingly connected with a rotating sleeve 16, and the rotating sleeve Both sides of 16 are fixedly connected with an inner housing 12, and the inner cavity of the inner housing 12 is connected with a first transmission gear plate 13 and a second transmission gear plate 15 through a rotating shaft, and the inner cavity of the inner housing 12 is provided with a first gear The winch 11 is co...

Embodiment 2

[0026] Embodiment two, refer to Figure 1-4 , the second transmission gear plate 15 is engaged with the threaded rod 8 and the first gear capstan 11 respectively, and the first transmission gear plate 13 is meshed with the first gear capstan 11 and the second gear capstan 14 respectively, and both ends of the threaded rod 8 run through At the left and right ends of the tube plate 10, the side walls at the two top ends of the threaded rod 8 are provided with helical blades 7, so that the helical blades 7 can obtain the rotation effect when the hull moves, so that the threaded rod 8 drives the first gear winch 11 to the first gear. The gear capstan 14 rotates and removes impurities for the cooling pipe 3 .

Embodiment 3

[0027] Embodiment three, refer to Figure 1-4 , the upper end surface of the rotating sleeve 16 is provided with a control rod 4, and the control rod 4 is fixedly connected with the end cover 1 through a nut, and there are a plurality of cooling pipes 3, and the upper end surfaces of the plurality of cooling pipes 3 are connected with a communication chamber 5, and communicated with each other. The cavity 5 is fixedly connected with the end cover 1, the inner and outer walls of the first gear winch 11 and the second gear winch 14 are in the form of threaded tooth grooves, and the inner and outer walls of the first gear winch 11 and the second gear winch 14 are connected with the cooling pipe 3 The outer wall is bonded, and there are fixing parts 6 on both sides of the upper end surface of the end cover 1. The cooling pipe 3 is made of titanium alloy, so that the corrosion resistance of the cooling pipe 3 is increased, and the speed of the cooling pipe 3 being damaged by corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com