Patents

Literature

38results about How to "Does not swell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite ecological wood

The invention provides composite ecological wood. The wood comprises the following compositions in percentage by weight: 35 to 40 percent of wood meal, 40 to 49 percent of PVC, 2 to 3 percent of calcium carbonate, 4 to 6 percent of a foaming regulator, 4 to 6 percent of a stabilizing agent, 4 to 6 percent of impact-resistant ACR, 0.5 to 1.5 percent of a processing additive ACR, 0.2 to 0.4 percent of toner, an internal lubricant and an external lubricant, a foaming agent accounting for 0.1 to 1 percent of the PVC and a coupling agent accounting for 3 to 5 percent of the wood meal; and when a product is used outdoors, the product also comprises an antioxidant, an ultraviolet absorbent and a light stabilizing agent which have 0.1 to 0.5 percent of weight portions respectively. Compared with the prior art, the composite ecological wood thoroughly overcomes the disadvantages of raw wood, improves the shortage of the raw wood and keeps the particular wooden texture of the raw wood; simultaneously, for the addition of the antioxidant, the ultraviolet absorbent and the light stabilizing agent, the composite ecological wood also prevents photooxidation, fading, cracking and the like caused by ultraviolet irradiation, increases the weather resistance and prolongs the service life.

Owner:孙玉武

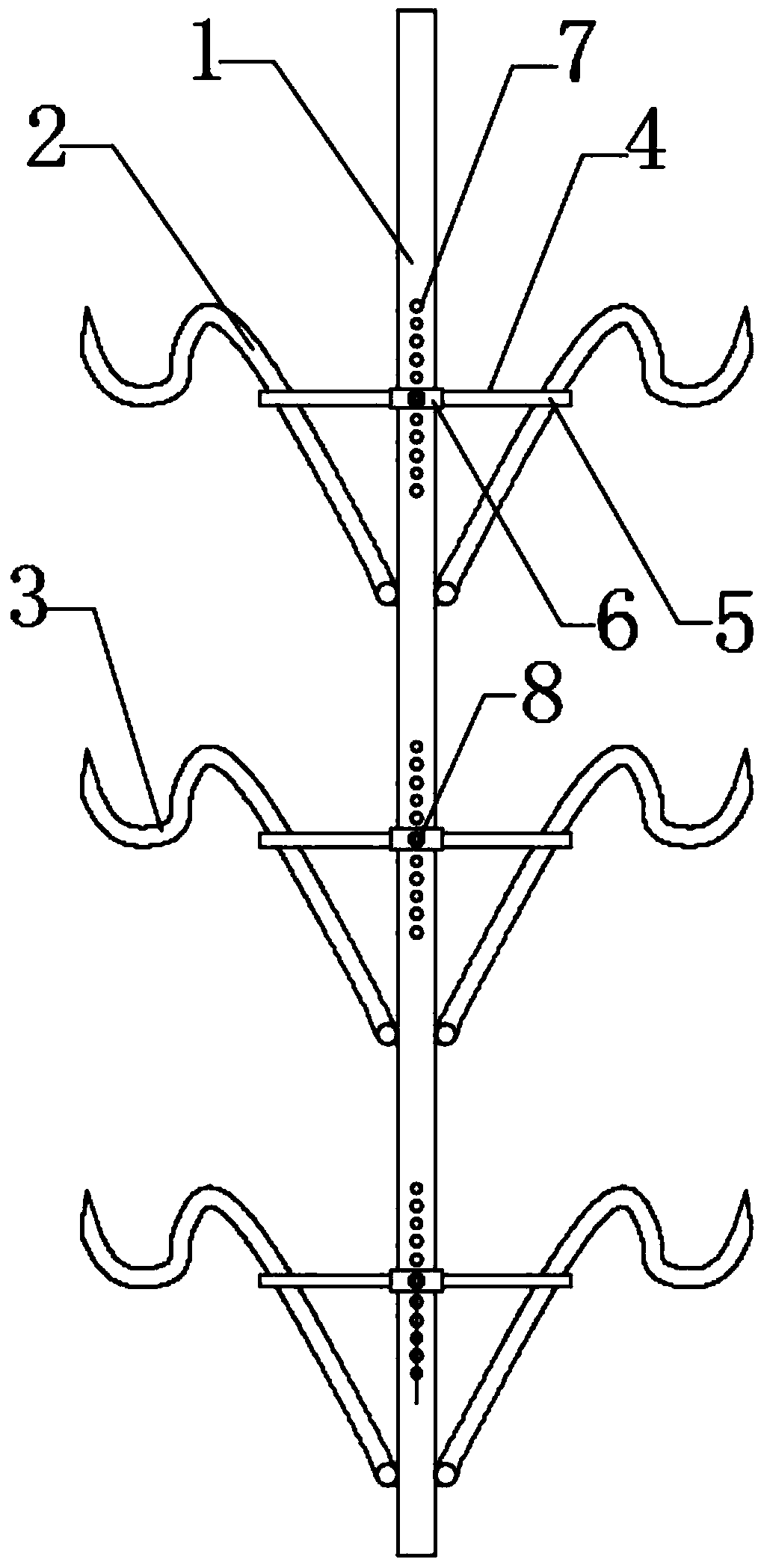

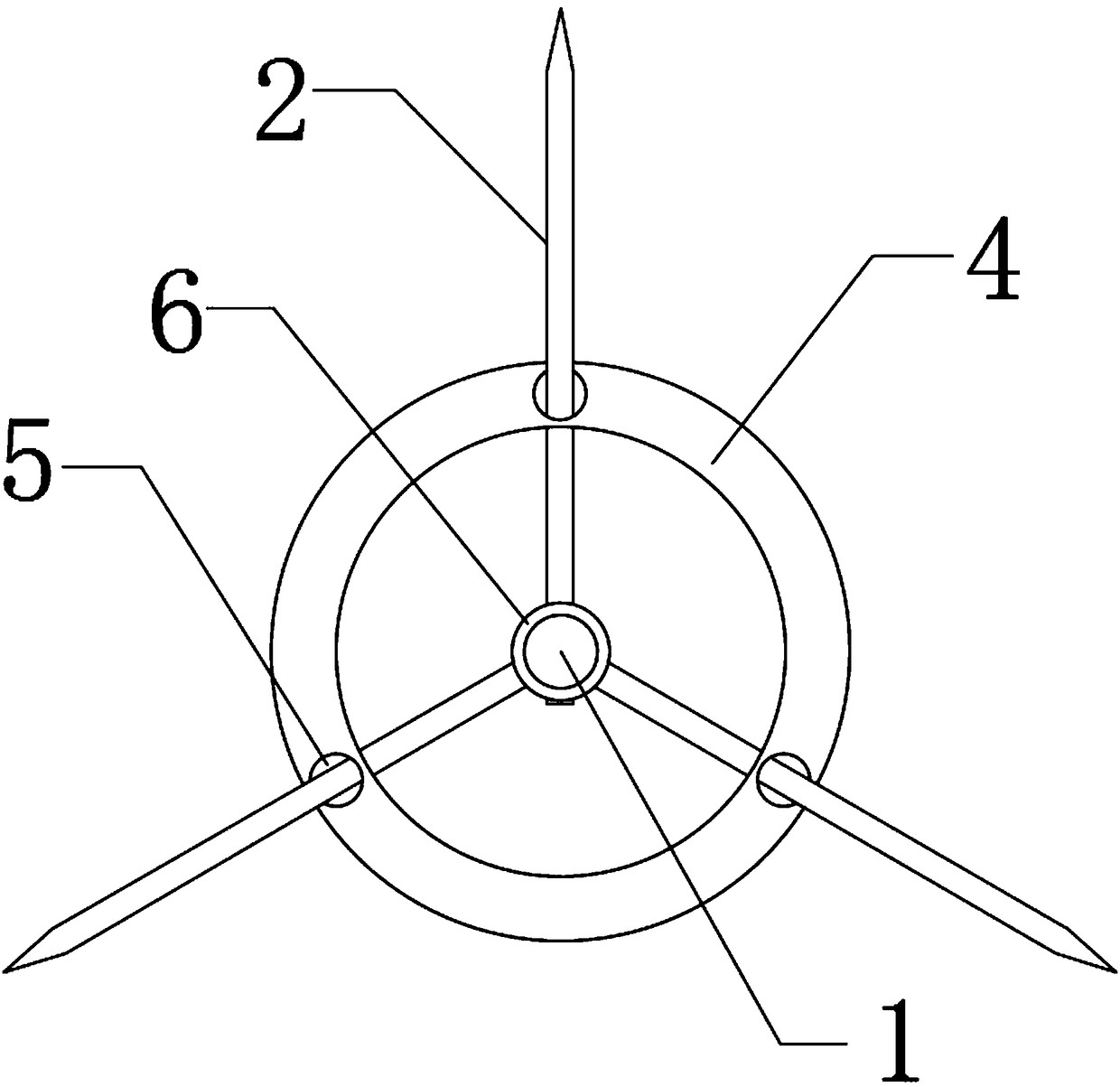

Method for manufacturing marble cutter bit and matrix material adopted for same

The invention discloses a method for manufacturing a marble cutter bit and a matrix material adopted for the method for the manufacturing the marble cuter bit. The matrix material of a diamond section in the marble cutter bit mainly comprises Cu-Zn-Sn alloy powder, Cu powder and Cu-Co-Fe alloy powder. The content of the low-melting-point metal component Sn and the content of low-melting-point metal component Zn in the matrix material are low, and the sintering temperature is high and can reach 820 DEG C and 860 DEG C. In the welding stage, the matrix material can be adaptive to the brazing technology, the cutter bit does not expand and is free of burning loss deformation and low in welding cost in the welding process, and the cutter bit has the cost competitive advantage and is broad in market prospect. Tests show that the bending strength of the marble cutter bit manufactured with the method ranges from 1000 Mpa to 1400 Mpa, and the hardness of the marble cutter bit manufactured with the method ranges from 80 HRB to 95 HRB; tests with a bridge cutting testing machine show that the power consumption ranges from 6 KW to 7 KW, the service life of the marble cutter bit can be 20 to 24 m<2> / mm, and compared with an exiting marble cutter bit, the marble cutter bit manufactured with the method has the advantages that the power consumption is lower and the service life is longer.

Owner:泉州众志金刚石工具有限公司

Energy-saving and environment-friendly wood plastic material

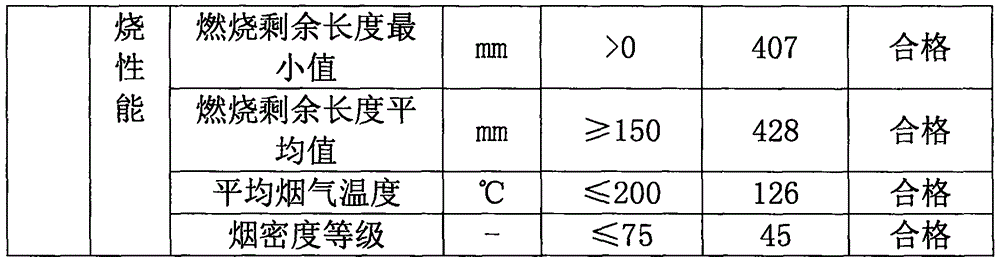

The invention discloses an energy-saving and environment-friendly wood plastic material, which consists of the following raw materials by mass: 40-60 parts of polyvinyl chloride resin powder, 30-40 parts of wood powder, 20-30 parts of calcium carbonate powder, 2-3 parts of a modifier, 3-5 parts of a processing aid, 2-3 parts of a foaming agent, 1-2 parts of a stable solvent, 1-2 parts of a foaming aid, 1-1.5 parts of a lubricant, and 0.5-1 part of a colorant. The wood plastic material has the characteristics of moisture protection, waterproofness, insect prevention, termite prevention, low carbon and energy saving, the product does not contain benzene, has a formaldehyde content of 0.2, which is lower than the EO level standard and meets the European grading standard, can realize recycling, greatly saves wood usage, is suitable for the national policy of sustainable development, and benefits the society. The whole production process does not generate industrial waste gas and waste water, is low in noise, and is in line with various national industrial production environmental protection requirements, thus being suitable for large-scale promotion and application.

Owner:高智慧

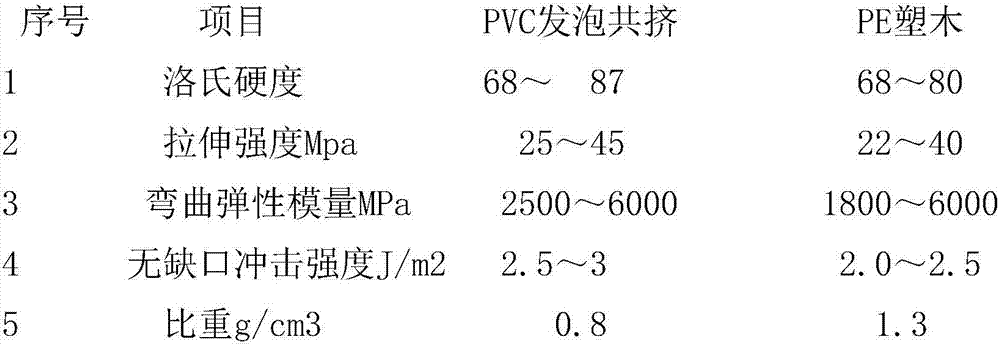

PVC foamed co-extruded floor preparation process

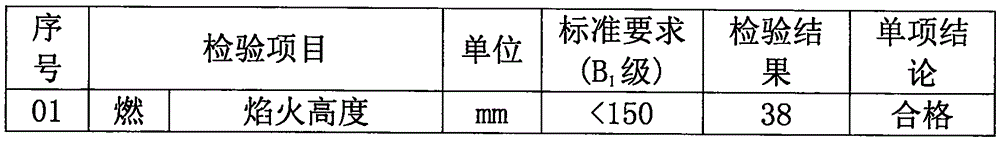

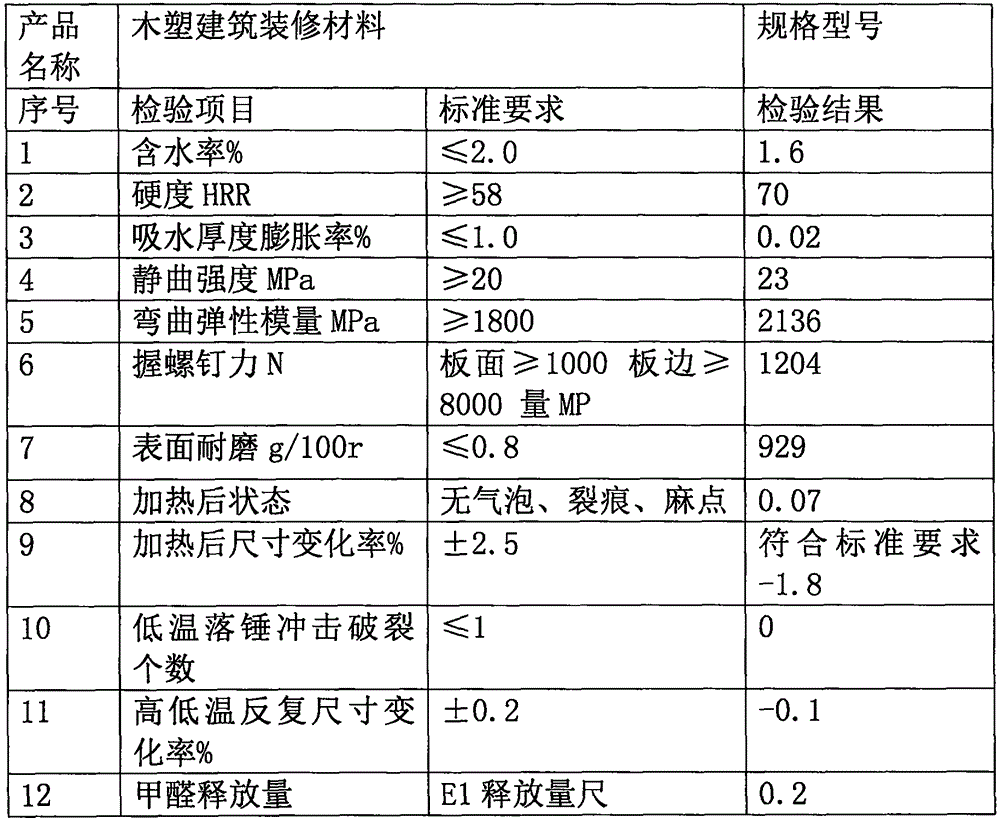

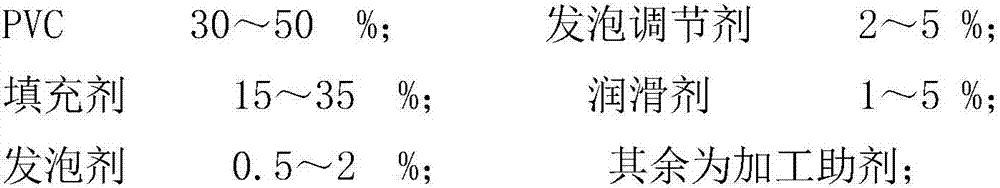

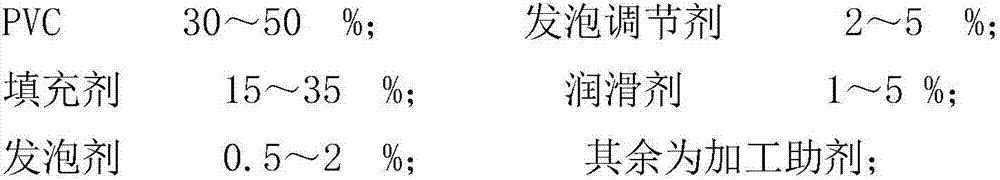

The invention provides a PVC foamed co-extruded floor preparation process, and relates to the technical field of production of plastics-wood materials. The floor preparation process mainly comprises the following steps: material mixing, extrusion foaming, co-extrusion and cooling and shaping production. In the material mixing process, 30-50% of PVC, 2-5% of foaming modifiers, 15-35% of filling agents, 1-5% of lubricating agents, 0.5-2% of foaming agents and processing agents are needed, wherein the percentage sum of all the components is 100%. In the material foaming process, high polymer materials cover foamed base materials through a co-extruder. The floor preparation process has the advantages that the water resistance and moisture resistance are achieved, the problem that the wood product is easy to rot and expand after absorbing water and being affected with the damp in a humid and moist environment is fundamentally solved, the plasticity is high, the personalized modeling can be realized very easily, the individual style is fully embodied, cracking is avoided, expansion is avoided, deformation is avoided, repair and maintenance are not needed, cleaning is facilitated, and later repair and maintenance cost is saved.

Owner:ANHUI SENTAI WPC GRP CO LTD

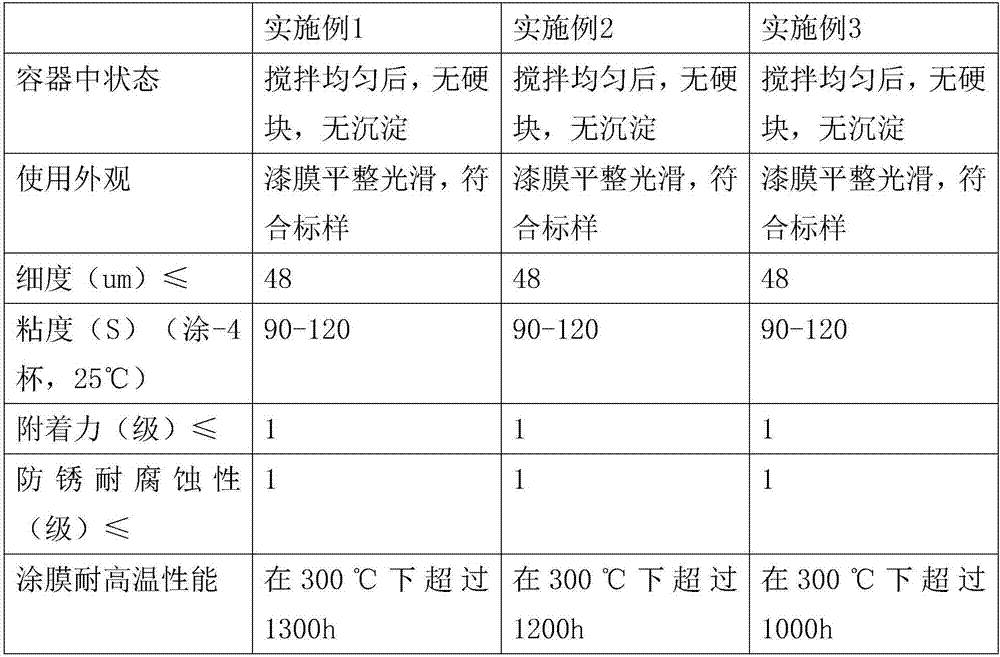

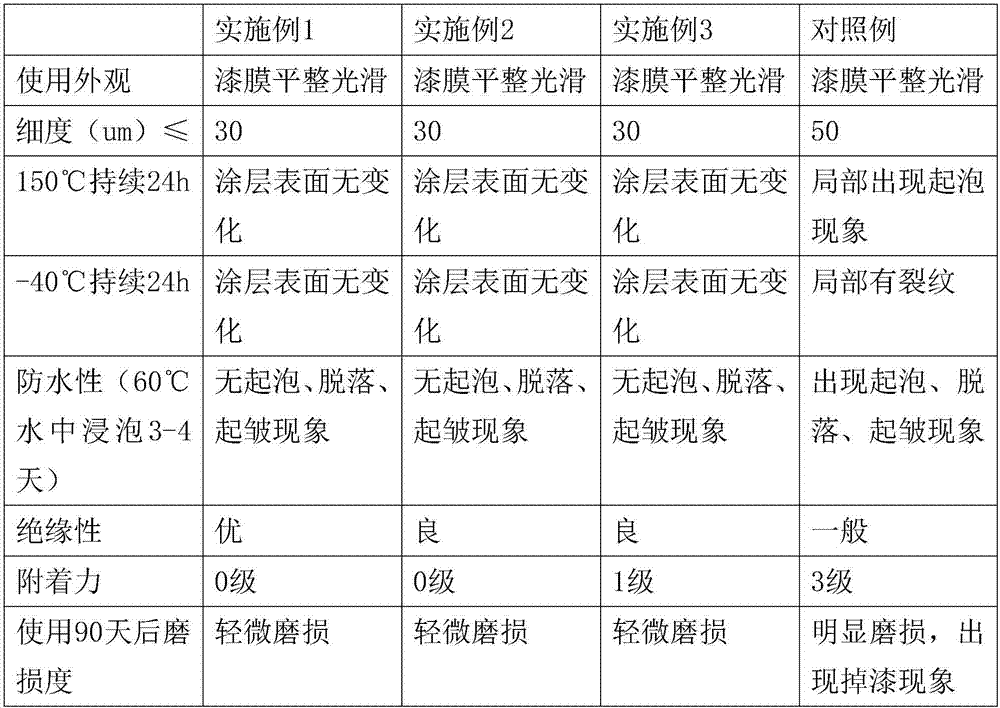

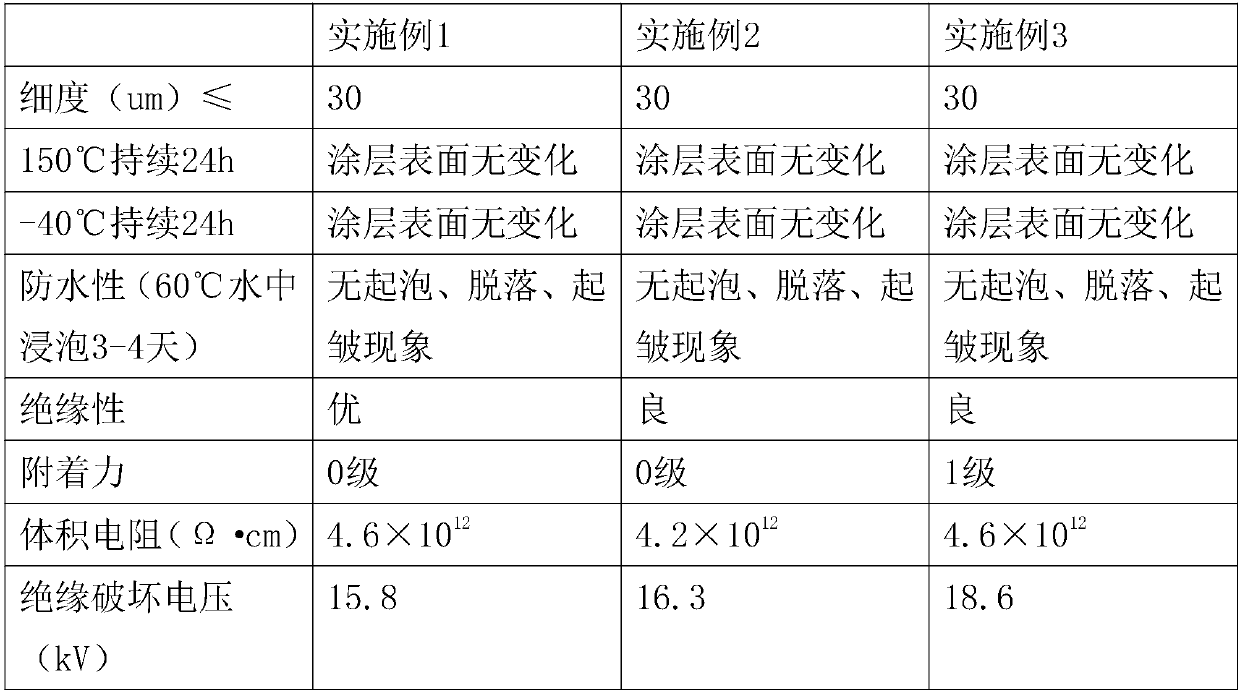

High temperature resistant and corrosion resistant coating for surface of distribution box and preparation method of high temperature resistant and corrosion resistant coating

InactiveCN107459929AGuaranteed to workExtended service lifeFireproof paintsAnti-corrosive paintsMethylanilineHigh resistance

The invention discloses a high temperature resistant and corrosion resistant coating for the surface of a distribution box and a preparation method of the high temperature resistant and corrosion resistant coating. The high temperature resistant and corrosion resistant coating for surface of the distribution box is prepared from the following raw materials in parts by weight: 50 to 80 parts of epoxy resin modified organic silicon resin, 10 to 20 parts of dimethylbenzene, 5 to 15 parts of propylene glycol, 5 to 8 parts of zinc naphthenate, 3 to 8 parts of tributyltin chloride, 3 to 5 parts of barium petroleum sulfonate, 3 to 10 parts of kerosene, 6 to 10 parts of lauryl diethanolamine, 2 to 8 parts of p-methylaniline, 5 to 8 parts of zinc powder, 3 to 6 parts of silicon nitride, 5 to 8 parts of chromium carbide, 5 to 10 parts of aluminium-plated glass micro-beads, 6 to 15 parts of silicon dioxide, 5 to 8 parts of aluminium oxide, 3 to 5 parts of calcium sulphate whisker powder, 5 to 10 parts of polytetrafluoroethylene, 5 to 10 parts of aloe juice, 10 to 20 parts of filler, 5 to 15 parts of pigment, 3 to 5 parts of a cardanol modified amine curing agent, 1 to 3 parts of a levelling agent, and 1 to 3 parts of an antifoaming agent. According to the high temperature resistant and corrosion resistant coating for the surface of the distribution box and the preparation method of the coating, reasonable raw materials and proportions are selected, so that the coating is dense and neat, does not crack, does not swell, does not fall off, and has high resistance to high temperature and corrosion; normal work of a distribution box is ensured; and the service life of the distribution box is prolonged.

Owner:安徽卓越电力设备有限公司

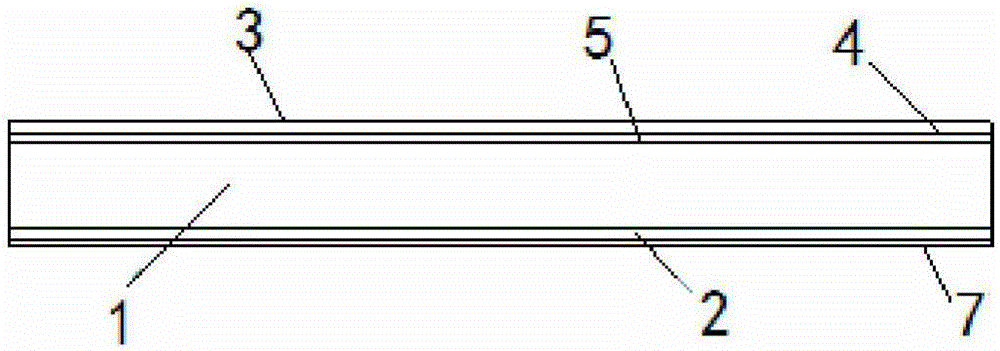

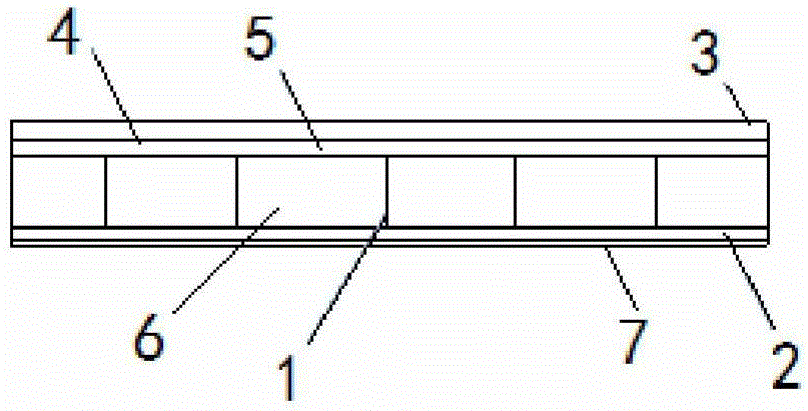

Antirust paint for water pump

InactiveCN107177258AImprove permeabilityStrong adhesionAnti-corrosive paintsPenetration forceLacquer

The invention discloses antirust paint for a water pump. The antirust paint for the water pump comprises three layers, namely, bottom paint, intermediate paint and surface paint, from inside to outside sequentially, wherein the bottom paint dries quickly, has high penetration force, excellent adhesive force, outstanding sealing property and dense and tight coating, and does not bleed, crack or swell; the intermediate paint is high in viscosity and good in waterproofness; the surface paint is high in adhesive force and hardness and resistant to scratch and stone chip.

Owner:ANHUI SANHUAN PUMP

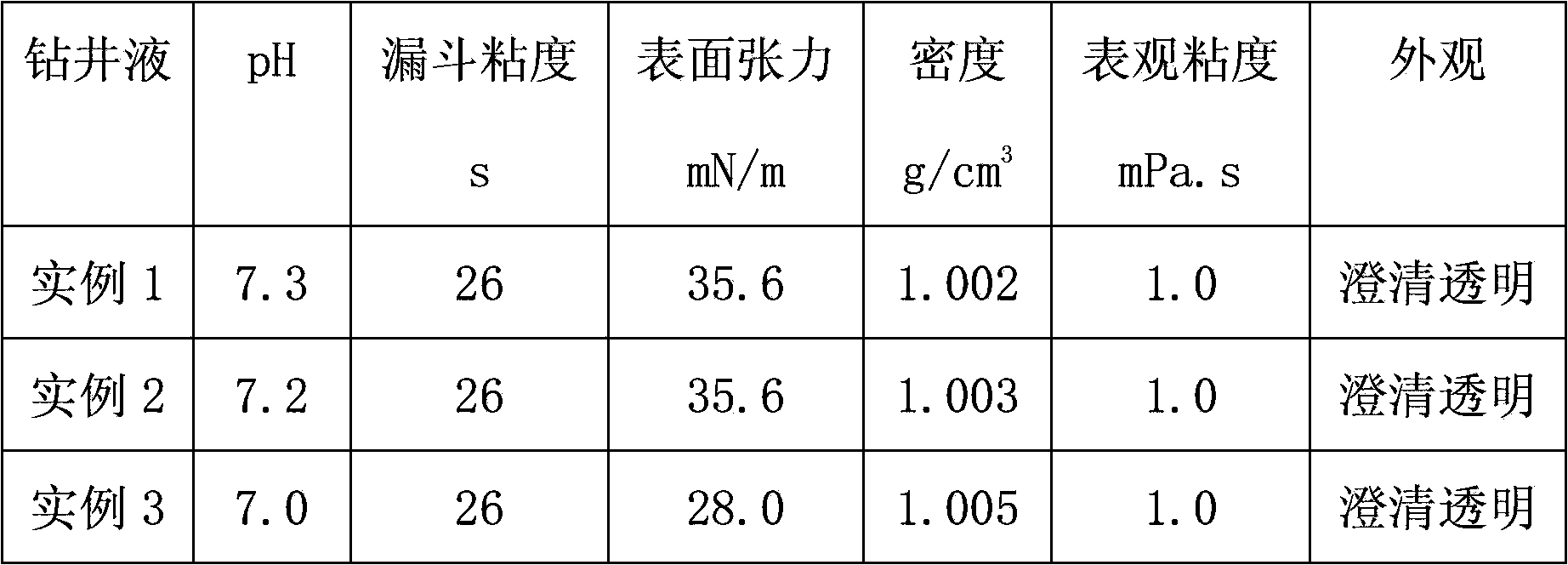

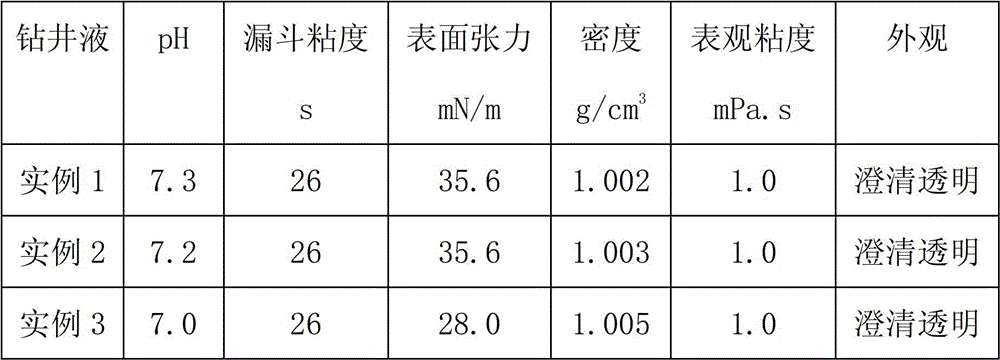

Horizontal well drilling fluid for protecting coal bed gas reservoir

InactiveCN103525381AGood compatibilityStrong interface activityDrilling compositionSurface tensionDrilling fluid

The invention relates to horizontal well drilling fluid for protecting a coal bed gas reservoir, belonging to the technical field of chemical agents of coal bed gas exploitation engineering. The horizontal well drilling fluid is characterized by comprising water, an anti-swelling agent, a discharge aiding agent, an anti-scaling agent and a flocculating agent; on the basis of the weight of 100% of water in percentage by weight, the anti-swelling agent accounts for 0.2-0.5%, the discharge aiding agent accounts for 0.05-0.1%, the anti-scaling agent accounts for 0.001-0.005%, and the flocculating agent accounts for 0.2-0.5%. The anti-swelling agent is industrial grade potassium chloride, and the discharge aiding agent is nonylphenol polyoxyethylene ether OP-10; the anti-scaling agent is 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP); the flocculating agent is liquid poly aluminum chloride (PAC). The horizontal well drilling fluid disclosed by the invention has appropriate degree of mineralization, can not form scales after being mixed with coal bed water, is low in surface tension and strong in interfacial activity, can flow back easily after invading a low-permeability coal bed, and has the characteristics of good compatibleness with the coal bed, strong flocculation ability, low cost and environment-friendliness.

Owner:YANGTZE UNIVERSITY

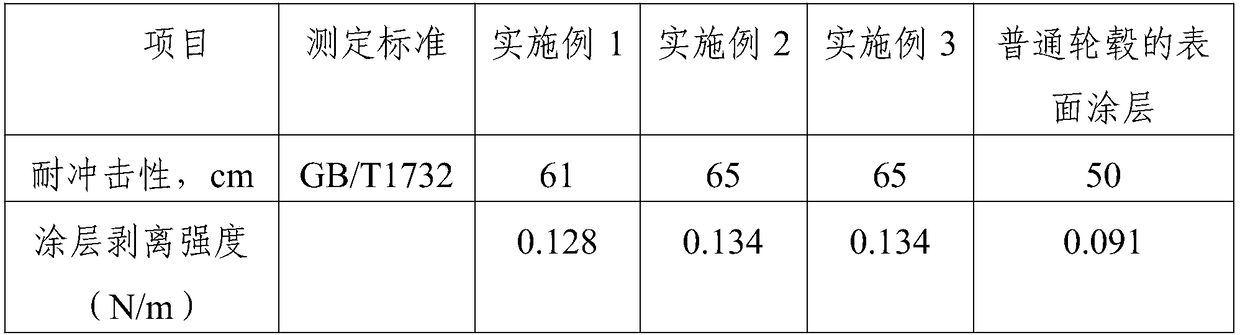

Spraying technology of wheel hub surface coatings

InactiveCN108165105AImprove adhesionGood sealingWax coatingsPretreated surfacesEngineeringCorrosion resistant

The invention provides a spraying technology of wheel hub surface coatings, and relates to the technical field of automotive component processing. The spraying technology comprises the following steps: performing surface treatment; fixing, namely, fixing a formed wheel hub on a hanging bracket well without touching places need to spray, and isolating the wheel hub from equipment by using rubber inholes of the wheel hub, so as to ensure that the wheel hub will not wear out; performing workpiece preheating and applying a primer to the wheel hub, namely, putting the workpiece into a heat treatment furnace for preheating, then putting the workpiece into an oven with a temperature of 115-140 DEG C, and staying for 25-45 min, so as to make the primer cured and the workpiece preheated; performing primary spraying; raising the temperature; and performing secondary spraying. According to the spraying technology, reasonable raw materials and proportions are selected and used, the raw materialswork synergistically and complement each other, the adhesion is extremely excellent, the sealing property is extremely good, the coating film is compact and neat, does not crack, does not swell, and is corrosion resistant, making the wheel hub can adapt to extremely complex environments.

Owner:ANHUI HENGXING WHEEL

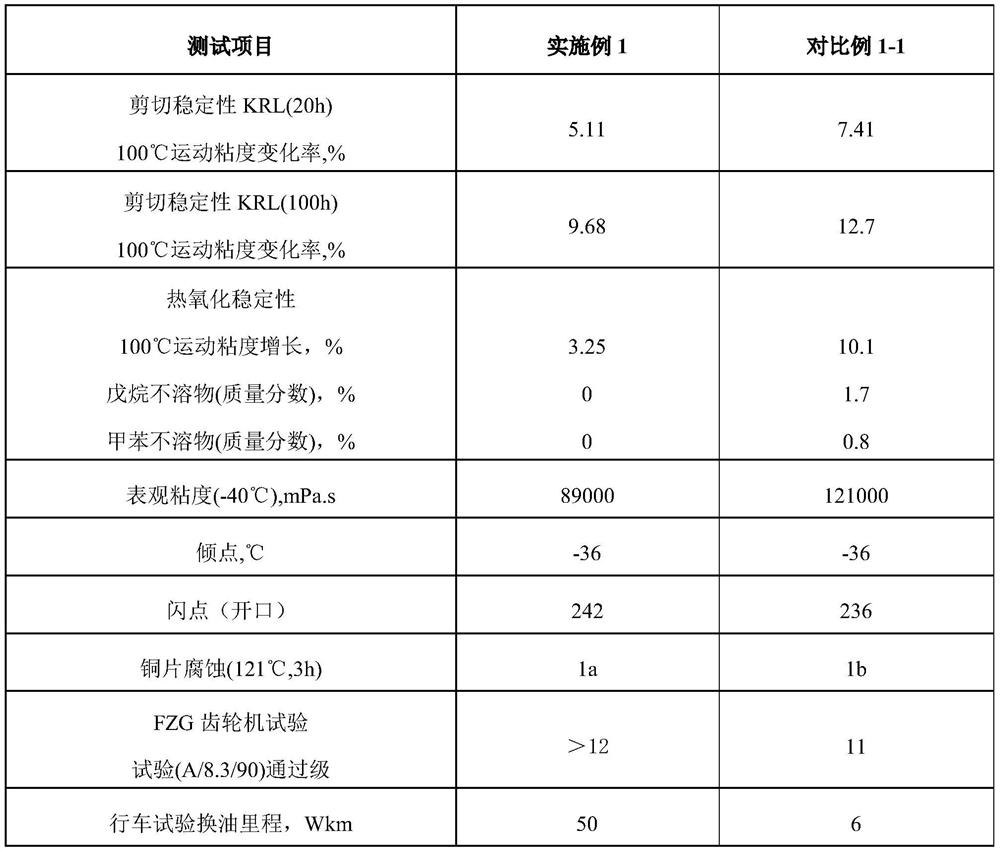

Long-life manual transmission oil composition

ActiveCN112080333AImprove performanceSufficient oil film thicknessLubricant compositionElastomerFoaming agent

The invention discloses a long-life manual transmission oil composition, which comprises the following components by weight percentage: 80%-90% of base oil; 5.0%-8.0% of a complexing agent; 0.8%-1.2%of an extreme pressure anti-wear agent; 3.0%-5.0% of a viscosity index improver; 0.6%-1.0% of a pour point depressant; and 0.03%-0.05% of an anti-foaming agent. According to the long-life manual transmission oil composition, the oil change mileage is as long as 50Wkm and is prolonged by 10 times compared with the most common oil change period 5-6Wkm of existing transmission oil. The long-life manual transmission oil composition provided by the invention has good detergency and dispersibility, oxidation and corrosion resistance, thermal stability, bearing resistance, elastomer compatibility andhigh-level shear stability, overall performance is improved, the service life of a vehicle gear transmission system can be effectively prolonged, and the oil change period of the vehicle gear transmission system can be effectively prolonged.

Owner:统一石油化工有限公司

Coating for transformer and preparation method of coating

The invention discloses a coating for a transformer and a preparation method of the coating. The coating is prepared from the following raw materials: epoxy modified organic silicon resin, hydroxyethyl cellulose, talcum powder, ceramic microspheres, propylene glycol methyl ether acetate, nanoscale aluminum oxide, nanoscale magnesium oxide, aluminum-doped zinc oxide, calcium stearate, slag powder, graphite, dimethylbenzene, water glass, n-butyl alcohol, a filler, a nonionic surfactant, a curing agent, a flatting agent and an anti-foaming agent. By selecting reasonable raw materials and ratios, various raw materials work together and are supplemented with each other, so that the coating is extremely good in adhesive force and excellent in closing property, and a film is compact and neat, free of cracking or swelling and high-temperature resistant.

Owner:安徽新智电力科技有限公司

Dual-component silicone sealant for solar photovoltaic components and preparation method thereof

ActiveCN101768421BIncrease productivityFast curing in deep layersNon-macromolecular adhesive additivesOther chemical processesTitaniumOmega

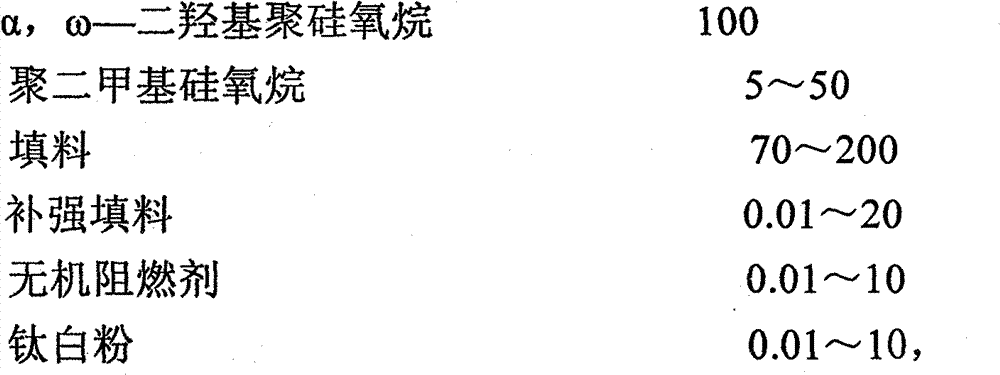

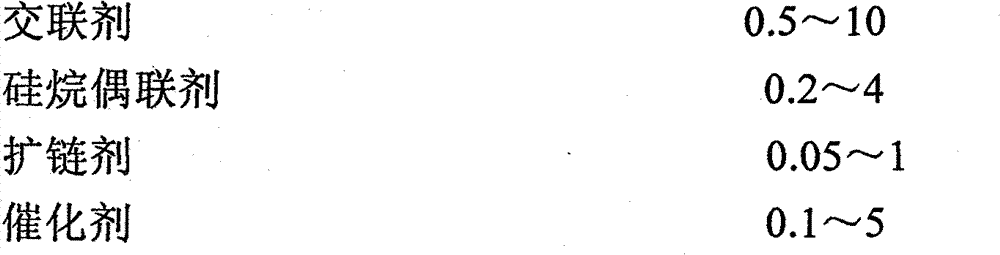

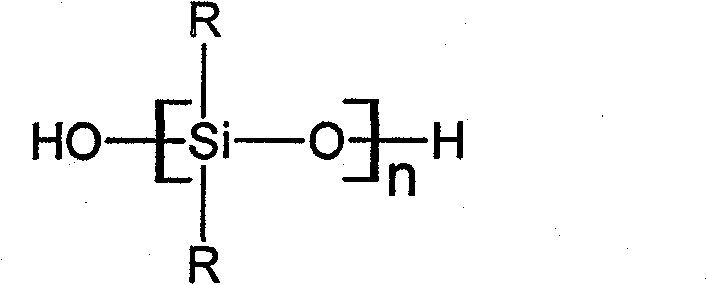

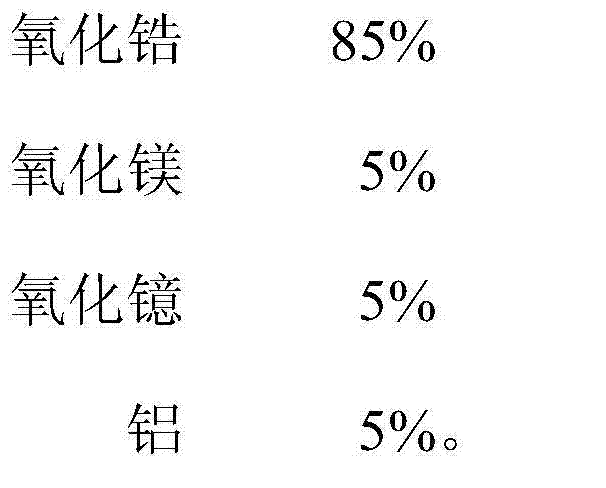

The invention discloses dual-component silicone sealant used in solar photovoltaic components and a preparation method thereof. The preparation method comprises the following steps: adding alpha, omega-dihydroxy polysiloxane, polydimethylsiloxane, filler, inorganic flame retardant, reinforcing filler and titanium pigment into a high-speed stirrer to perform dehydration for 0.5 to 4 hours at the temperature of between 90 and 150 DEG C at a vacuum degree of 0.06 to 0.1 MPa and cooling the product of the dehydration to prepare A component; adding crosslinking agent, silane coupling agent, chain extender and catalyst into a closed container and stirring the mixture uniformly to obtain B component; and uniformly mixing A and B components according to a ratio equal to 100:8-15 and defoaming themixture at a vacuum degree of 0.06 to 0.1 MPa for 10 to 30 minutes to obtain the dual-component silicone sealant for solar photovoltaic components. The dual-component silicone sealant prepared by themethod has the advantages of strong binding power, quick deep solidification, high yellowing resistance and high price-to-performance ratio and is time-saving and labor-saving when used in photovoltaic component sealing and applicable to seal photovoltaic components.

Owner:湖北雨虹兴发新材料有限公司

Antirust temperature-resistant primer

InactiveCN104087096AEasy to useDoes not fall offAnti-corrosive paintsPolyvinyl alcoholTemperature resistance

The invention discloses an antirust temperature-resistant primer. The primer comprises the following raw materials in parts: 20-30 parts of ethanol, 20-25 parts of xylene, 15-20 parts of dimethylformamide, 15-20 parts of ethyl acetate, 10-15 parts of ethylene-propylene latex solution, 15-20 parts of pure acrylic latex solution, 5-15 parts of diatom mud, 5-8 parts of dibutyl phthalate, 5-10 parts of ammonium persulfate, 5-8 parts of polyvinyl alcohol resin, 15-18 parts of phosphoric acid, 5-10 parts of hydrochloric acid, 5-12 parts of ferrous oxide, 12-15 parts of copper oxide, 5-10 parts of silica, 5-10 parts of iron hydroxide, 5-10 parts of bentonite, 5-10 parts of activated clay, 3-5 parts of montmorillonite, 5-10 parts of heavy calcium carbonate and 50-80 parts of deionized water. The antirust temperature-resistant primer has the advantages of rust-removal performance, antirust performance, high-temperature resistance, water resistance, convenience in application and salt water resistance, the coating does not fall off or generate bubbles, the coating film does not crack and does not fall off or protrude, and no swelling or color bleeding is generated.

Owner:司徒建辉

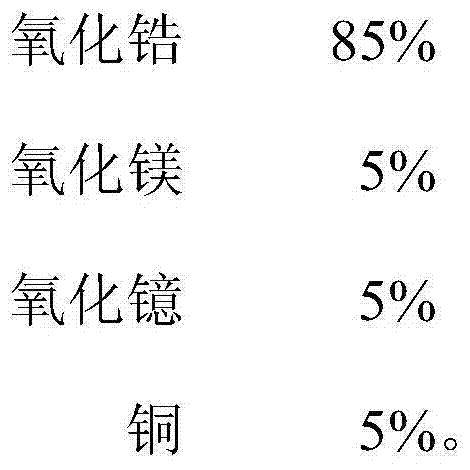

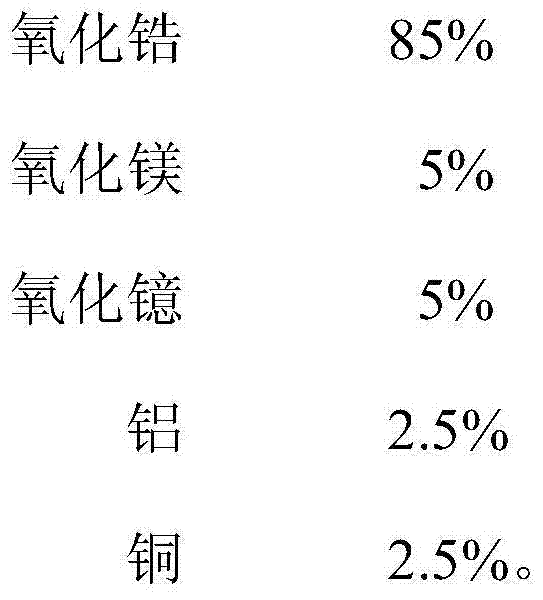

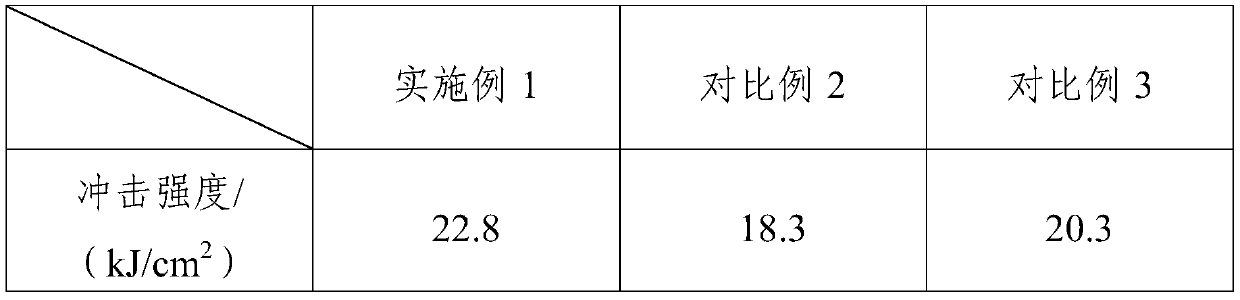

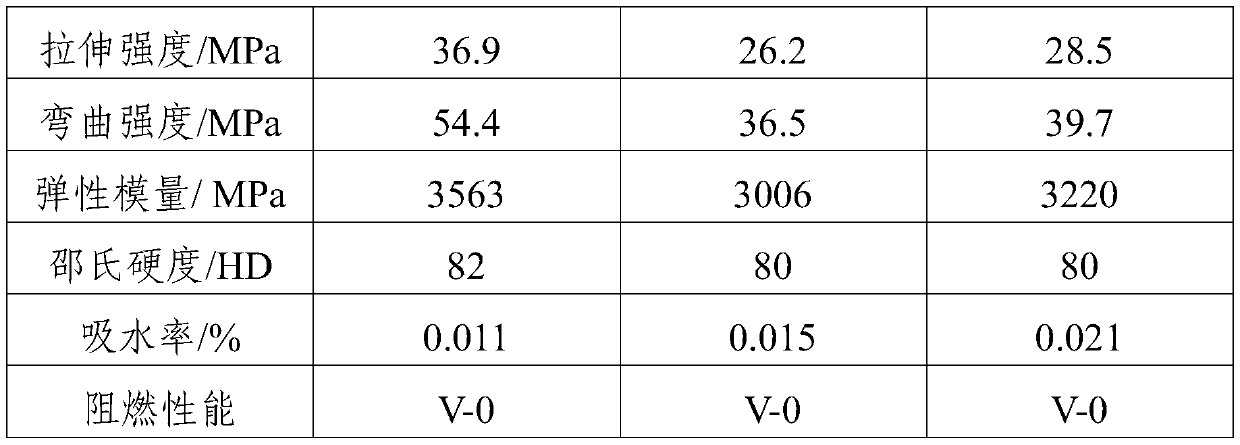

Zirconia ceramic center bar and preparation method thereof

The invention relates to a zirconia ceramic center bar and a preparation method thereof. The preparation method comprises the following processing steps of: weighing raw materials according to a formula amount and uniformly mixing the raw materials; putting the raw materials into a mold so that the mold is filled with the raw materials; sealing an opening of the mold; inserting the mold into a metal pipe, putting in an isostatic oil press and compression-molding the raw materials in the mold with the isostatic oil press; taking the mold out of the isostatic oil press and putting the mold on an alumina hollow ball brick; then putting the alumina hollow ball brick placed with the mold into an oven for prebaking for 3-4 hours at the temperature of 70-80 DEG C; taking a zirconia bar from the mold and sinter-molding the zirconia bar, wherein the sintering temperature is 1450-1480 DEG C and the sintering time lasts for 35-45 hours; putting the zirconia bar into a centerless grinding machine for processing and molding to obtain a finished product. The center bar has no deformation, no expansion, long service life and good heat dispersion; the preparation method of the zirconia ceramic center bar is simple in process and high in production efficiency.

Owner:永州明睿陶瓷科技有限公司

Anti-corrosive and anti-aging coating for disc type vacuum filter

InactiveCN107739574AExtended service lifeImprove adhesionAnti-corrosive paintsBituminous coatingsCalcium bicarbonateSolvent

The invention discloses an anti-corrosive and anti-aging coating for a disc type vacuum filter. The anti-corrosive and anti-aging coating is prepared from the following components in parts by weight:60 to 100 parts of No.60 petroleum asphalt, 25 to 40 parts of polyvinylidene fluoride glue, 10 to 28 parts of ethylene and vinyl acetate copolymer, 5 to 10 parts of calcium rosin, 2 to 5 parts of 400-mesh calcined magnetic powder, 2 to 7 parts of 400-mesh talcum powder, 5 to 6 parts of 500-mesh calcium carbonate, 10 to 12 parts of 800-mesh calcium bicarbonate, 1 to 3 parts of 800-mesh sierozem, 2to 5 parts of sodium hexametaphosphate, 1 to 2 parts of quartz powder, 1 to 2 parts of kaolin, 2 to 10 parts of fluorocarbon resin, 1 to 2 parts of pentaerythritol, 1 to 2 parts of melamine, 1 to 2 parts of titanium dioxide powder, 1 to 2 parts of adhesion force accelerant, 1 to 5 parts of viscosity adjusting solvent, 1 to 2 parts of dispersant, and 1 to 2 parts of defoaming agent. The anti-corrosive and anti-aging coating has the advantages that the reasonable raw material and proportional ratio are selected, the raw materials cooperate together in a synergistic way, the adhesion force is better, the sealing property is better, the coating film is dense and tight, the cracking and swelling are avoided, the anti-corrosive property is realized, and the service life of the filter is prolonged.

Owner:邵莹

Waste tire rubber powder and agricultural straw filling type plastic-wood composite profile

InactiveCN110982292AWide variety of sourcesImprove mechanical propertiesFiberPolyethylene terephthalate glycol

The invention provides a waste tire rubber powder and agricultural straw filling type plastic-wood composite profile, and relates to the field of plastic-wood composite materials. The composition comprises the following components in parts by weight: 60-80 parts of agricultural straw; 20-40 parts of polyethylene glycol terephthalate; 20-40 parts of polyolefin plastic powder; 20-40 parts of waste tire rubber powder; 10-20 parts of gutta-percha; 10-30 parts of starch-coated calcium carbonate; 5-10 parts of polyethylene wax; 1-5 parts of maleic anhydride graft polymer; 0.1-2 parts of silane coupling agent; 1-10 parts of acicular wollastonite; 10-20 parts of reinforcing fibers; 1-5 parts of microencapsulated ammonium polyphosphate; 1-2 parts of rosin pentaerythritol ester; 0.1-1 part of tri (stearic acid) antimony heat stabilizer; and 0.1-1 part of AMB impact modifier. The plastic-wood composite profile has excellent mechanical properties and is flame-retardant and moisture-proof and alsoproves that the addition of the waste tire rubber powder and the eucommia ulmoides gum is greatly beneficial to the improvement of the mechanical properties of the plastic-wood composite profile.

Owner:安徽壹聘网科技有限公司

Forming process of composite particle board

InactiveCN110871484AFaster molding timeReduce pollution and wasteWood working apparatusDomestic articlesScrapAdhesive

Owner:中山市富门木制品有限公司

Ceramic coating

InactiveCN108395818AHas high temperature oxidation resistanceWith thermal shock resistanceFireproof paintsEpoxy resin coatingsEpoxyCellulose

The invention provides a ceramic coating which is prepared from the following raw materials in parts by weight: 70 to 100 parts of ceramic micro powder, 25 to 35 parts of epoxy resin, 60 to 70 parts of asbestos fiber, 20 to 30 parts of submicron ceramic powder, 18 to 26 parts of sodium phosphate, 18 to 26 parts of silicon dioxide, 15 to 20 parts of alkyl cellulose, 7 to 13 parts of titanium dioxide, 8 to 16 parts of titanium nitride, 10 to 17 parts of hydroxymethyl cellulose, 11 to 19 parts of polysiloxane, 6 to 10 parts of calcium oxide, 4 to 8 parts of silicon dioxide and 30 to 50 parts of water. The ceramic coating has high-temperature oxidation resistance and thermal shock resistance; a coating film of the ceramic coating is compact and strict, cannot be cracked or swollen and has goodacid resistance and alkali resistance; the ceramic coating is environmental-friendly and safe.

Owner:黄建如

Wear-resistant and anti-corrosion coating for corrugating machine

InactiveCN107880667AExtended service lifeImprove adhesionAnti-corrosive paintsPolyamide coatingsCelluloseWear resistant

The invention discloses a wear-resistant and anti-corrosion coating for a corrugating machine. The coating is prepared from, by weight, 60-100 parts of polyvinylidene fluoride glue, 30-60 parts of resin, 6-12 parts of polylaurylamide, 10-20 parts of turpentine oil, 5-10 parts of 140 mesh mica powder, 5-10 parts of cellulose, 10-15 parts of sodium tripolyphosphate, 2-5 parts of nitric lime, 2-5 parts of diatomaceous earth, 1-3 parts of melamine, 1-3 parts of graphite powder, 1-2 parts of aluminum powder, 5-8 parts of beeswax, 2-5 parts of tapioca starch, 3-5 parts of curing agent, 5-10 parts ofadhesion promoter, 3-8 parts of viscosity adjusting solvent, 2-5 parts of dispersant, 5 -7 parts of coupling agent, 5-10 parts of biological rust inhibitor and 2-5 parts of adjuvant. The coating hasreasonable selection of reasonable raw materials and ratios, so that the raw materials work synergistically and complement each other, thus the coating achieves excellent adhesion, excellent sealing property, dense and tight coating films, no cracking, and no swelling, is wear-resistant and anti-corrosion, and can prolong the service life of the corrugating machine.

Owner:BENGBU ZHENHUA PACKING MACHINERY

A blockboard produced by soybean protein glue and its process method

ActiveCN103737677BImprove plasticityIncrease elasticityProtein adhesivesWood veneer joiningSolid woodGrip force

The invention relates to a core board produced with soy protein glue and a technique of production, and belongs to the technical field of wood board production. A first soy protein glue layer is arranged between board cores; the board cores and the first soy protein glue layer are combined into a combined center board of board cores and first soy protein glue layer; a second soy protein glue layer is arranged between the top of the combined center board and a white blank layer; the other side of the white blank layer is connected with a first veneer layer; a third soy protein glue layer is arranged between the bottom of the combined center board and the second veneer layer. Compared to solid wood, the core board and the technique of production have the advantages that resources are saved, the appearance is more attractive and elegant, compression ratio is higher than that of a common multi-ply board, the core structure is more compact, compactness is higher, nail gripping force is larger, and the core board has high bending resistance and compressive strength; the core board has low water content and is free of expansion, shrinking and deformation; the soy protein glue used as binder has low volatility and never fails; the core board produced has good hot water tolerance and completely meets the requirements of national standard for type-II plywood.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

Production method of bamboo-wood fiber door plate

InactiveCN111978754AAddress perishableSolve expansion deformationLaminationLamination apparatusBenzeneAdhesive

The invention discloses a production method of a bamboo-wood fiber door plate, belongs to the technical field of door plate processing, and solves the problems that in the prior art, a door plate is prone to rot, expansion deformation and termite erosion after being affected with damp, the content of benzene-containing substances and formaldehyde exceeds the standard, the door plate is prone to cracking and deformation, and maintenance is difficult. The production method is characterized in that polyvinyl chloride resin, calcium carbonate and bamboo wood are adopted as raw materials and mixed;a door plate base material is formed after double-screw shearing, extrusion and water cooling forming through a shaping mold; a water-based adhesive is sprayed after the door plate base material is subjected to thickness fixing, engraving and door leaf grinding; the door plate base material is coated with a film or subjected to double fixation of UV glue; and the bamboo-wood fiber door plate is prepared. The bamboo-wood fiber door plate has the characteristics of being waterproof, dampproof, insect-proof, termite-proof, high in environmental protection property, free of pollution, recyclable,free of cracking, expansion and deformation and free of maintenance.

Owner:浙江启德新材料有限公司

Coating used for electric automobile shell

InactiveCN107779016AFlame retardantImprove adhesionFireproof paintsElectrically-conductive paintsFiberAluminum doped zinc oxide

The invention discloses coating used for an electric automobile shell. The coating is prepared from the following raw materials in parts by weight: 15-25 parts of quartz powder, 15-25 parts of vinyl acetate-vinyl chloride copolymer, 4-7 parts of talcum powder, 4-7 parts of ceramic microbeads, 4-7 parts of Propylene glycol monomethyl ether acetate, 4-7 parts of nanoscale aluminum oxide, 3-5 parts of file stearate, 3-5 parts of aluminum-doped zinc oxide, 15-25 parts of calcium stearate, 15-25 parts of chlorophyll, 15-25 parts of graphite, 5-7.5 parts of guar gum ether, 5-7.5 parts of chlorinatedparaffin, 5-7.5 parts of musa textilis nee fibers, 5-7.5 parts of filler, 2-4 parts of a nonionic surfactant, 2-4 parts of a curing agent and 2-4 parts of organosilicon modified polyurethane. The coating disclosed by the invention has the advantages that reasonable raw materials and ratio are selected, all the raw materials are synergistic and supplement each other, adhesion is excellent, closeness is excellent, and a film is compact and rigorous, does not crack or expand and is resistant to high temperature and antistatic, so that the coating is applicable to an electric automobile and the coating has flame retardant property.

Owner:ANHUI BAODAO NEW ENERGY DEV

Hydration-resistant magnesia chrome castable for nonferrous metallurgical furnaces and preparation method thereof

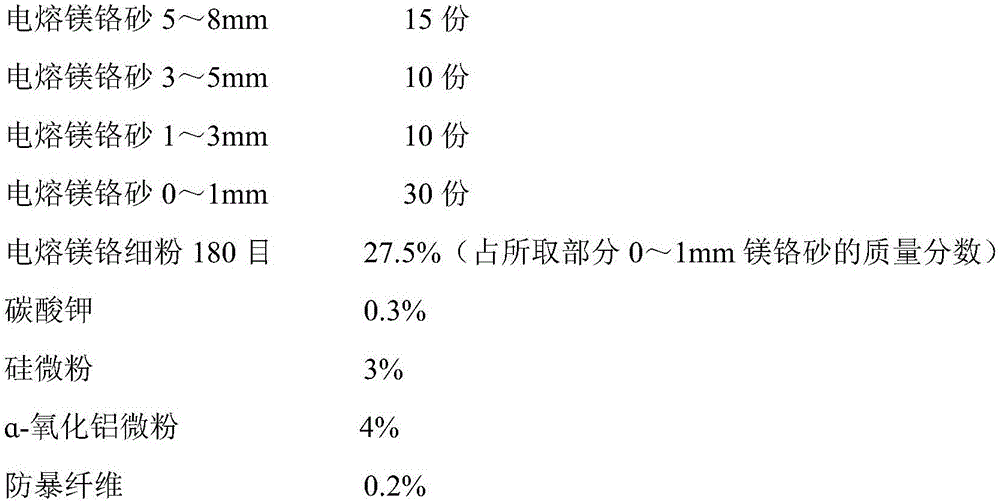

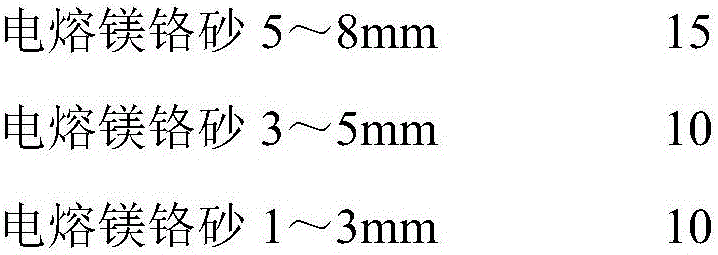

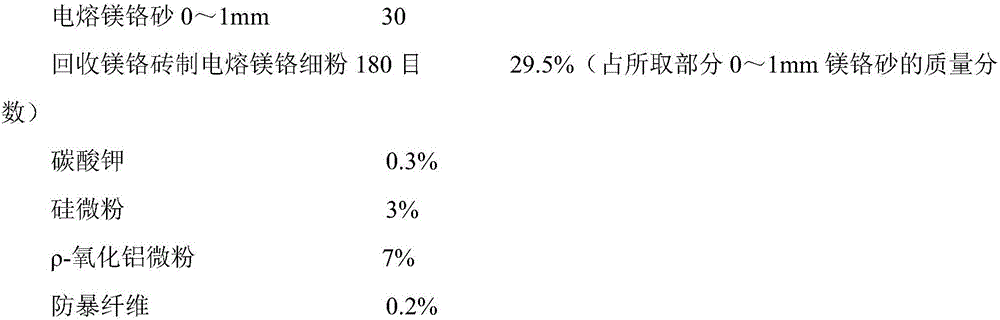

The invention discloses a hydration-resistant magnesia chrome castable for nonferrous metallurgical furnaces and a preparation method thereof, and belongs to the technical field of nonferrous metallurgical refractory materials. Raw materials of the castable contain magnesia chrome particles, a hydration-resistant matrix and a hydration-resistant low-temperature sintering aid. The magnesia chrome particles contain, by weight, 15 parts of magnesia chrome sand with particle size being 5-8 mm, 10 parts of magnesia chrome sand with particle size being 3-5 mm, 10-15 parts of magnesia chrome sand with particle size being 1-3 mm, and 30-35 parts of magnesia chrome fine-powder and magnesia chrome sand with particle size being 0-1 mm. The hydration-resistant low-temperature sintering aid is potassium carbonate, which accounts for 0.3-1.0% of mass of the magnesia chrome particles. The magnesia chrome fine-powder is coated with stearic acid. Problems of magnesia chrome castable, such as short storage life in actual use process, easy hydration and swelling in casting process and low service strength at low temperature, are solved. The invention lays a foundation for large-scale use of the magnesia chrome castable.

Owner:郴州市恒达环保科技有限公司

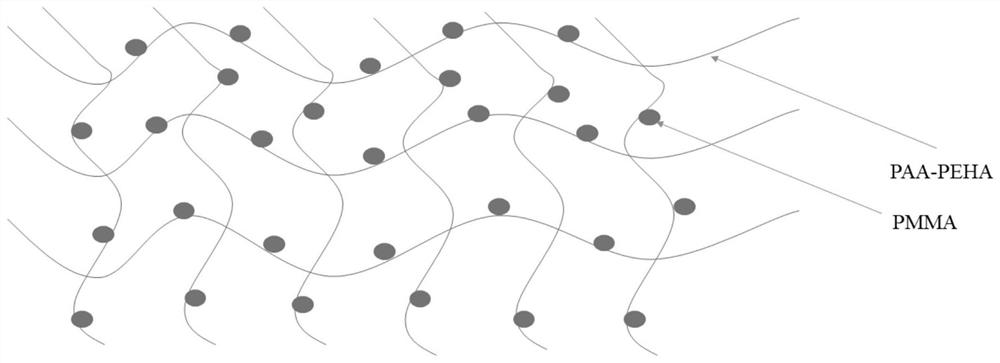

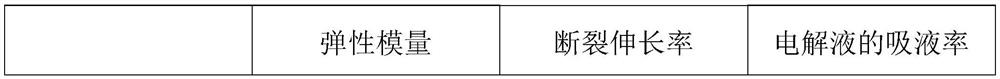

Modified water-based binder as well as preparation method and application thereof

ActiveCN113066982AReduce usageIncrease the proportionCell electrodesSecondary cellsIsooctyl acrylateElectrolytic agent

The invention provides a modified water-based binder as well as a preparation method and application thereof. The modified water-based binder comprises a main monomer, a soft monomer and a homopolymer, wherein the main monomer comprises polyacrylate, the soft monomer comprises copolymerized 2-benzoyl-3-hydroxy-1-propylene and / or 2-ethylhexyl acrylate, the homopolymer comprises polymethyl methacrylate, and the binder is relatively high in overall bonding strength, relatively good in dispersity and stable in performance in an electrolyte.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

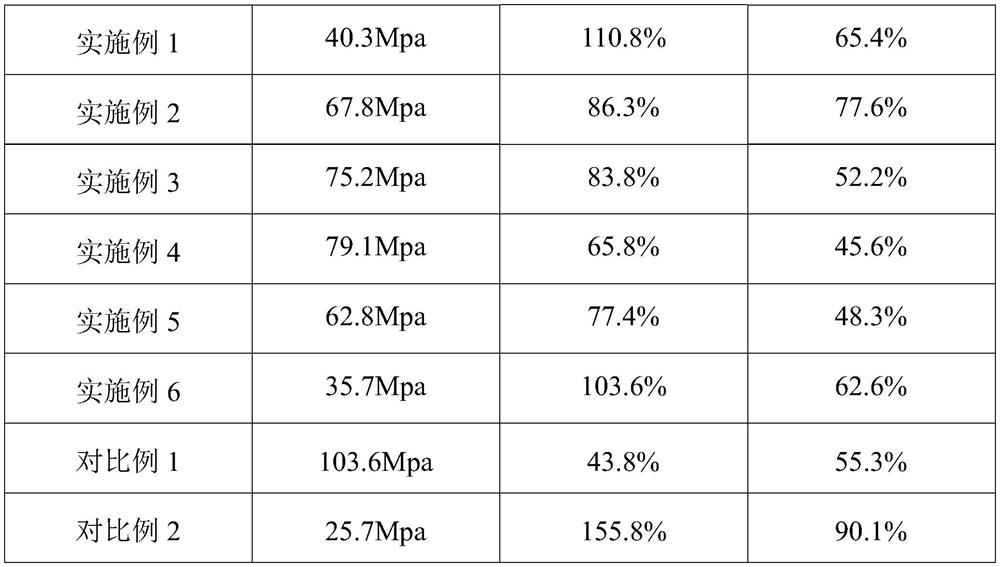

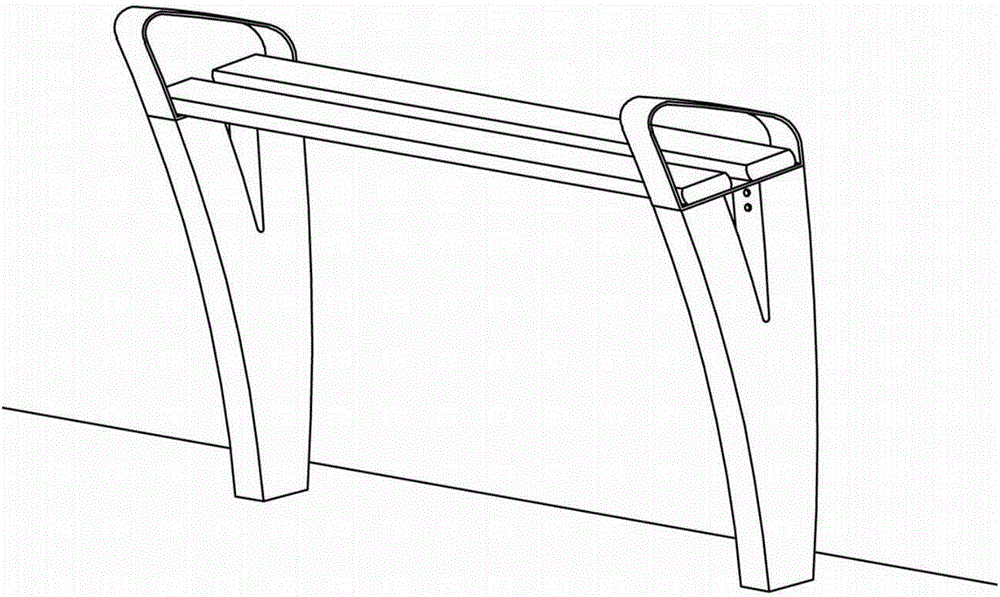

Cant arm-chair

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Preparation method of marble cutter head and matrix material used

The invention discloses a preparation method of a marble cutter head and the used matrix material. In the present invention, the matrix material of the diamond segment in the marble cutter head is mainly composed of Cu-Zn-Sn alloy powder, Cu powder and Cu-Sn alloy powder. Made of Co-Fe alloy powder, the low-melting-point metal components Sn and Zn content in this carcass material is low, the sintering temperature is high, up to 820-860 ° C, the welding stage can adapt to the brazing process, and the blade does not expand during the welding process , No burning deformation, low welding cost, the product has a cost competitive advantage, and the market prospect is great. The marble cutter head prepared by the method of the present invention has a flexural strength of 1000-1400MPa and a hardness of 80-95HRB according to test measurements. When tested with a bridge cutting test machine, the power consumption is 6-7KW and the service life can reach 20-24m2 / mm, power consumption and lifespan are superior to existing marble cutter heads.

Owner:泉州众志金刚石工具有限公司

A horizontal well drilling fluid for protecting coalbed methane reservoirs

The invention relates to horizontal well drilling fluid for protecting a coal bed gas reservoir, belonging to the technical field of chemical agents of coal bed gas exploitation engineering. The horizontal well drilling fluid is characterized by comprising water, an anti-swelling agent, a discharge aiding agent, an anti-scaling agent and a flocculating agent; on the basis of the weight of 100% of water in percentage by weight, the anti-swelling agent accounts for 0.2-0.5%, the discharge aiding agent accounts for 0.05-0.1%, the anti-scaling agent accounts for 0.001-0.005%, and the flocculating agent accounts for 0.2-0.5%. The anti-swelling agent is industrial grade potassium chloride, and the discharge aiding agent is nonylphenol polyoxyethylene ether OP-10; the anti-scaling agent is 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP); the flocculating agent is liquid poly aluminum chloride (PAC). The horizontal well drilling fluid disclosed by the invention has appropriate degree of mineralization, can not form scales after being mixed with coal bed water, is low in surface tension and strong in interfacial activity, can flow back easily after invading a low-permeability coal bed, and has the characteristics of good compatibleness with the coal bed, strong flocculation ability, low cost and environment-friendliness.

Owner:YANGTZE UNIVERSITY

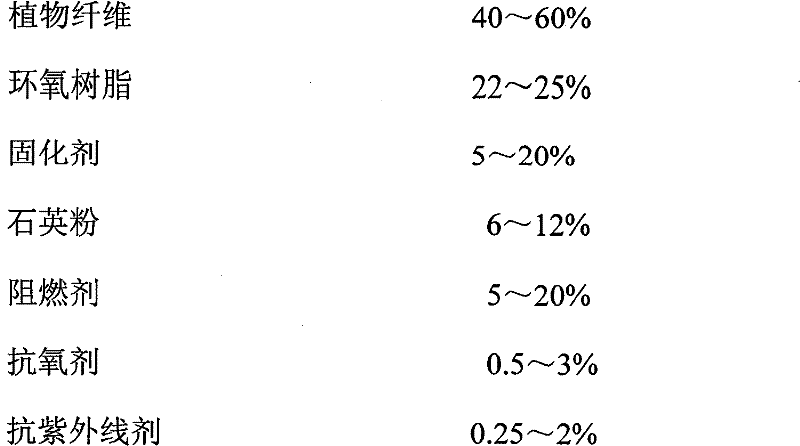

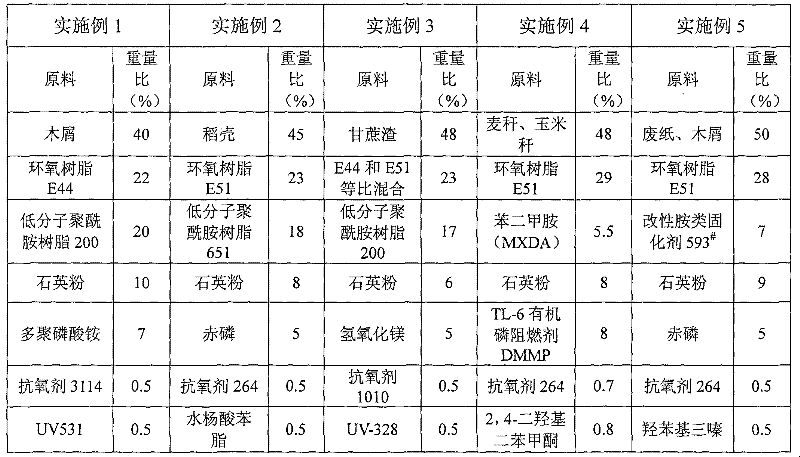

Plant fiber road material, preparation method and construction method thereof

The invention discloses a plant fiber road material, the raw materials of which comprise a plant fiber, an epoxy resin, a curing agent, quartz powders, a fire retardant, an antioxidant and an ultraviolet resistant agent, wherein the curing agent refers to the polyamide curing agent. In the inventive road material, the plant fiber is the major raw material, which is rich in source and low in cost,is absolutely environment-friendly and is regenerative, thereby meeting the national encouragement policy of utilizing regenerative resources. The invention further discloses a preparation method of the plant fiber road material, and a construction method of road surfacing by using the plant fiber road material.

Owner:CHONGQING POFUN TRAFFIC TECH

Manufacturing method of iron handicraft

PendingCN114083932AStrong adhesionGood sealingWax coatingsSpecial ornamental structuresMetallurgyMegasonic cleaning

The invention discloses a manufacturing method of an iron handicraft, which comprises the following steps of: firstly, polishing a prepared handicraft by using a machine, and blowing the handicraft to be clean by using a blower gun for later use; secondly, putting the artware in the first step into an ultrasonic cleaning machine to be cleaned, and removing surface dirt; thirdly, putting the artware in the second step into a drying box to be dried; fourthly, putting the artware in the third step into a mold, and injecting a rubber solution into the mold; and fifthly, coating the surface of the rubber layer in the artware in the step four with a layer of rubber adhesion treating agent, then uniformly spraying antirust paint, after the artware is naturally air-dried, polishing the surface by using 1000-mesh abrasive paper, then heating the product to 48 DEG C, then spraying a layer of antirust paint, and after the artware is naturally air-dried and secondarily polished, enabling the surface to be smooth. The manufacturing method provided by the invention has the advantages of strong adhesive force, excellent sealing property, compact and tight film, no bleeding, no cracking, no swelling and no shedding.

Owner:泉州咏鑫工艺品科技有限公司

A kind of manufacturing method of phenolic resin glue for bamboo and wood integrated profiles

InactiveCN104493941BHigh densityAchieve semi-ceramic effectNon-macromolecular adhesive additivesWood working apparatusCarbonizationEngineering

Owner:安吉明微智科技有限公司

Paint for electromobile housing

InactiveCN108559396AFlame retardantImprove adhesionFireproof paintsElectrically-conductive paintsFiberChlorinated paraffins

The invention discloses paint for an electromobile housing, which comprises the following raw materials in parts by mass: 20-25 parts of silicon carbide, 20-25 parts of organic silicon resin, 5-8 parts of dimethyl itaconate, 3-6 parts of graphite, 3-6 parts of mica, 3-6 parts of quartz powder, 0.2-0.3 parts of ethenyl ethanoate-vinyl chloride copolymer, 0.2-0.3 parts of ceramic microbead, 0.5-0.8parts of aupoz fiber, 0.5-0.8 parts of guar gum ether, 0.2-0.3 parts of aluminum nitride, 0.5-0.8 parts of natrolite, 0.1-0.2 parts of organic chelated titanium, 15-18 parts of aluminum, 0.1-0.2 partsof chlorinated paraffin, 0.1-0.2 parts of calcium carbonate and 0.1-0.2 parts of zinc borate. The paint adopts the reasonable raw materials and proportions; the raw materials have a synergistic effect and supplement each other; and the paint is excellent in adhesion, very good in closeness, dense and tight to apply, free from cracking and expansion, resistant to high temperature, antistatic and very applicable to an electromobile, and has flame resistance.

Owner:ANHUI HEYI NEW ENERGY VEHICLE CHARGING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com