Spraying technology of wheel hub surface coatings

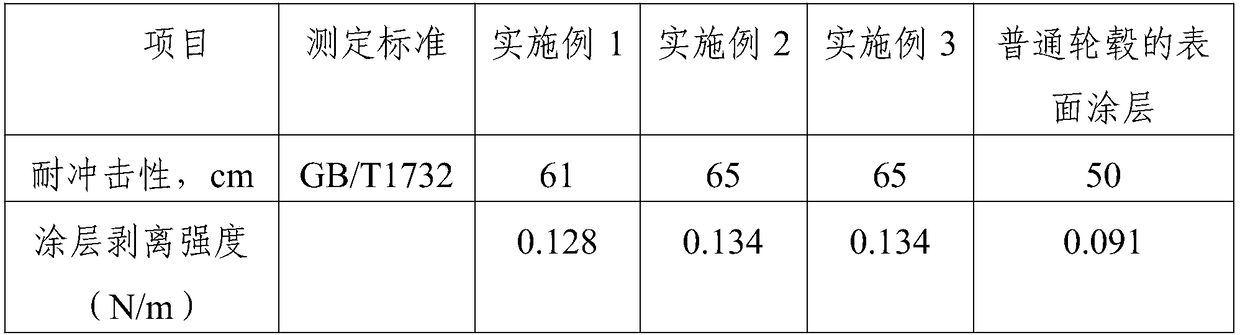

A technology of wheel hub surface and coating, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, can solve the problems of increasing manufacturing cost, lengthening production cycle, and troublesome wheel hub spraying, and achieves good sealing, Excellent adhesion, compact and tidy coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of spraying process of hub surface coating, comprises the steps:

[0024] ①Surface treatment: use ethanol to clean the hub surface and inner wall surface to remove surface pollutants;

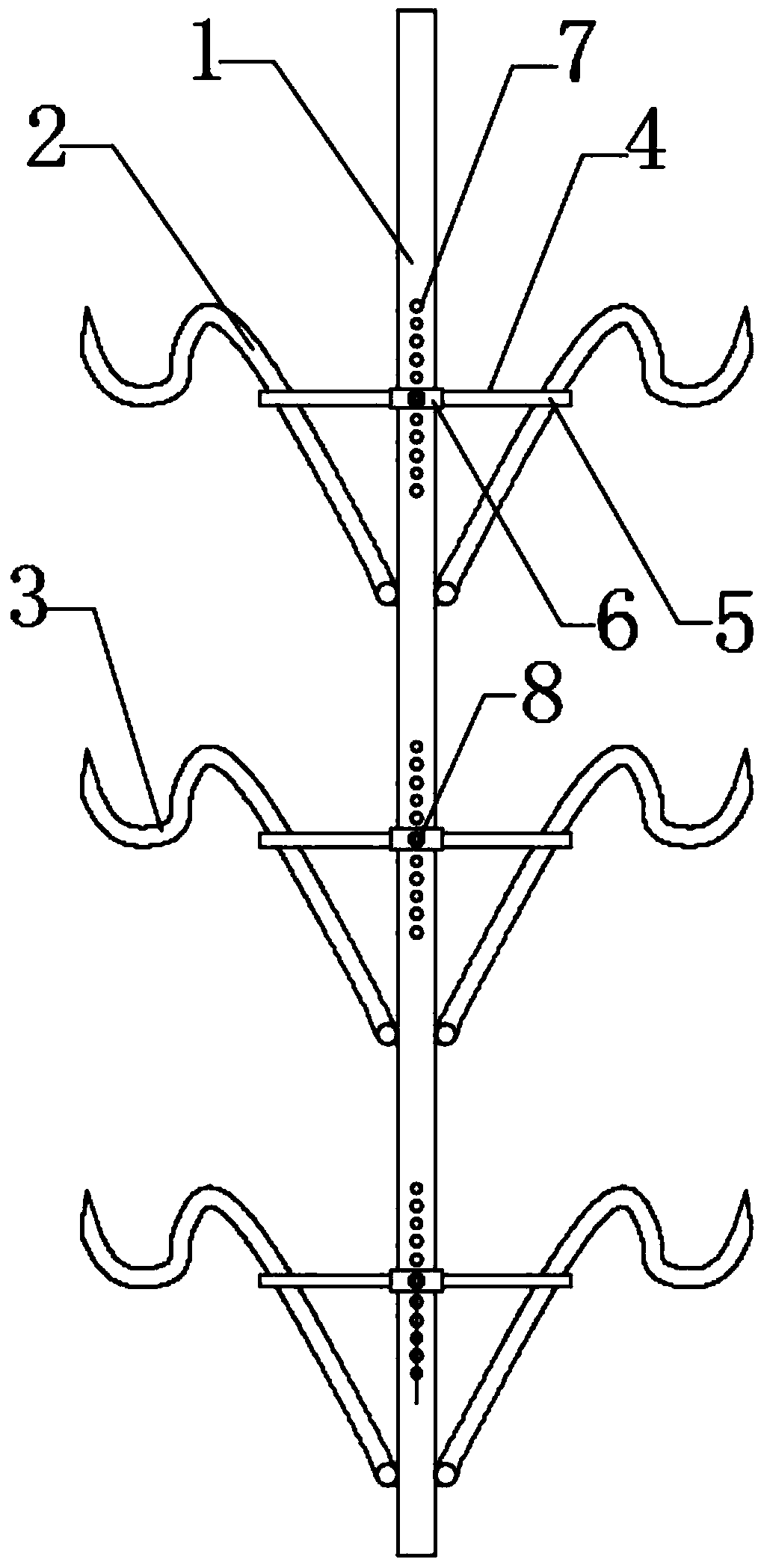

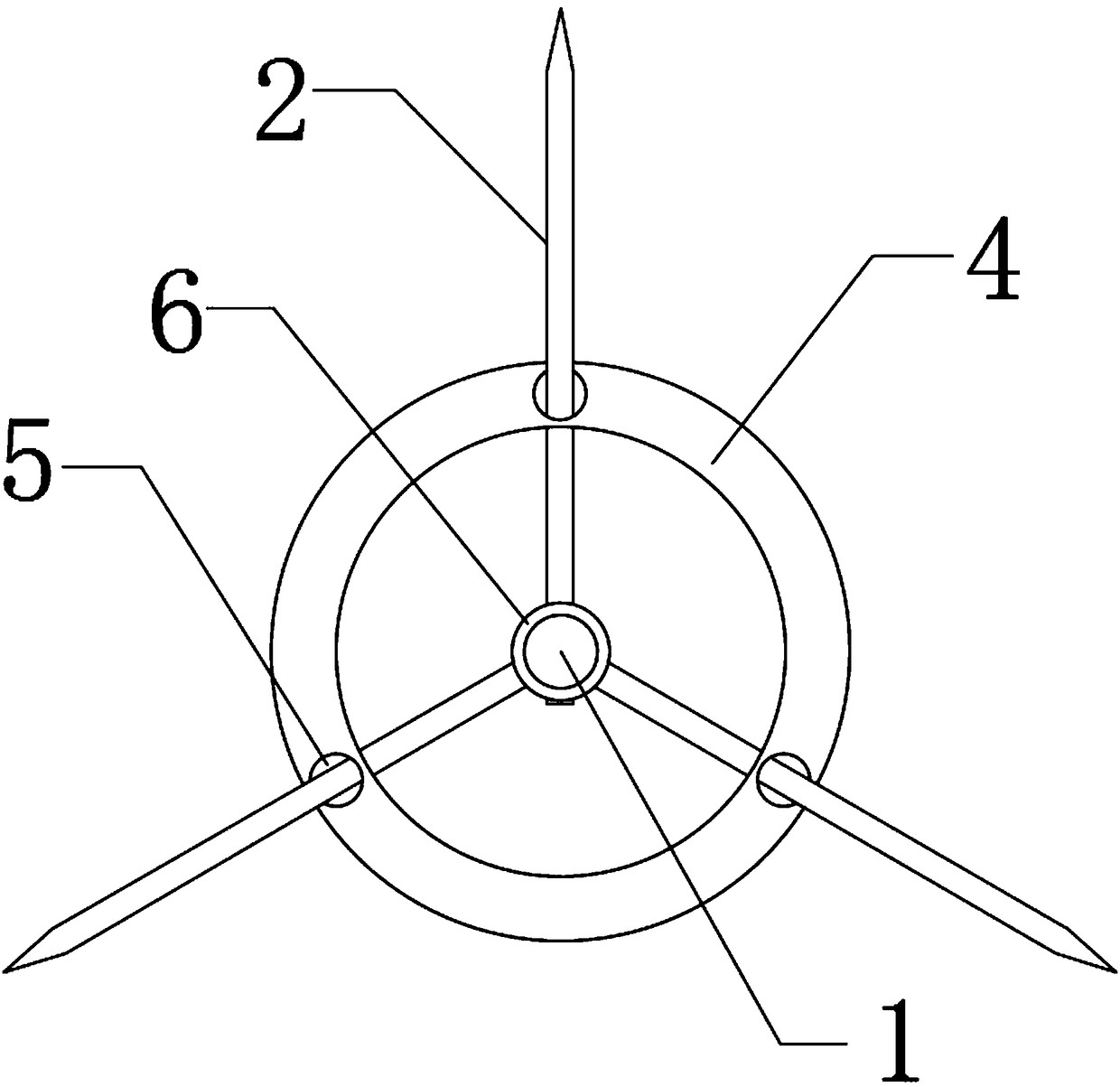

[0025] ② Fixing: Fix the formed wheel hub on the suspension bracket well, do not touch the place that needs to be sprayed, and use rubber in the hole of the wheel hub to isolate it from the equipment to ensure that the wheel hub will not be worn;

[0026] ③Workpiece preheating: apply primer to the hub, put the workpiece into a heat treatment furnace for preheating, and place it in an oven at a temperature of 115°C-140°C for 25min-45min, so that the primer is cured and the workpiece is preheated;

[0027] ④ One-time spraying: Use a small-caliber spray gun to spray the protective coating on the surface and inner wall of the hub, the spraying pressure is 0.20-0.30MPa, and the spraying distance is 10-20cm;

[0028] ⑤Heating up: use the electric heating plate heating method to heat up...

Embodiment 2

[0031] A kind of spraying process of hub surface coating, comprises the steps:

[0032] ①Surface treatment: use ethanol to clean the hub surface and inner wall surface to remove surface pollutants;

[0033] ② Fixing: Fix the formed wheel hub on the suspension bracket well, do not touch the place that needs to be sprayed, and use rubber in the hole of the wheel hub to isolate it from the equipment to ensure that the wheel hub will not be worn;

[0034] ③Workpiece preheating: apply primer to the hub, put the workpiece into a heat treatment furnace for preheating, and place it in an oven at a temperature of 115°C-140°C for 25min-45min, so that the primer is cured and the workpiece is preheated;

[0035] ④ One-time spraying: Use a small-caliber spray gun to spray the protective coating on the surface and inner wall of the hub, the spraying pressure is 0.20-0.30MPa, and the spraying distance is 10-20cm;

[0036] ⑤Heating up: use the electric heating plate heating method to heat up...

Embodiment 3

[0040] A kind of spraying process of hub surface coating, comprises the steps:

[0041] ①Surface treatment: use ethanol to clean the hub surface and inner wall surface to remove surface pollutants;

[0042] ② Fixing: Fix the formed wheel hub on the suspension bracket well, do not touch the place that needs to be sprayed, and use rubber in the hole of the wheel hub to isolate it from the equipment to ensure that the wheel hub will not be worn;

[0043] ③Workpiece preheating: apply primer to the hub, put the workpiece into a heat treatment furnace for preheating, and place it in an oven at a temperature of 115°C-140°C for 25min-45min, so that the primer is cured and the workpiece is preheated;

[0044] ④ One-time spraying: Use a small-caliber spray gun to spray the protective coating on the surface and inner wall of the hub, the spraying pressure is 0.20-0.30MPa, and the spraying distance is 10-20cm;

[0045] ⑤Heating up: use the electric heating plate heating method to heat up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com