Zirconia ceramic center bar and preparation method thereof

A zirconia ceramic and zirconia technology, applied in the field of zirconia ceramic center rod and its preparation, can solve the problems of easy expansion, short service life, easy to rust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A zirconia ceramic center rod of the present invention comprises the following raw materials in mass percentage:

[0050] Zirconia 80%

[0053] The zirconia in this embodiment is a mixture of cubic zirconia and nano zirconia at a mass ratio of 3:1.

[0054] A method for preparing a zirconia ceramic center rod, comprising the following processing steps:

[0055] Step A. Accurately weigh the raw materials according to the formula quantity and mix them uniformly for later use;

[0056] Step B. Put the uniformly mixed raw materials in step A into the mold using the combination of the vibration motor and the mold, so that the raw materials fill the mold, and the raw materials are tightly combined, and the opening of the mold is closed;

[0057] Step C. Insert the mold into the metal tube, then put the metal tube into the isostatic hydraulic press, and use the isostatic hydraulic press to compact the raw materials...

Embodiment 2

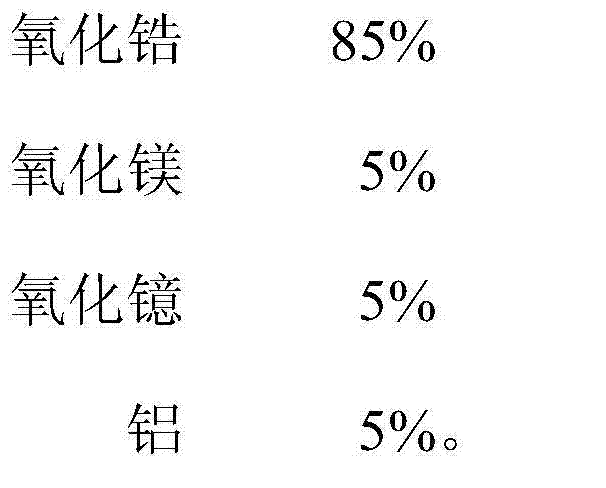

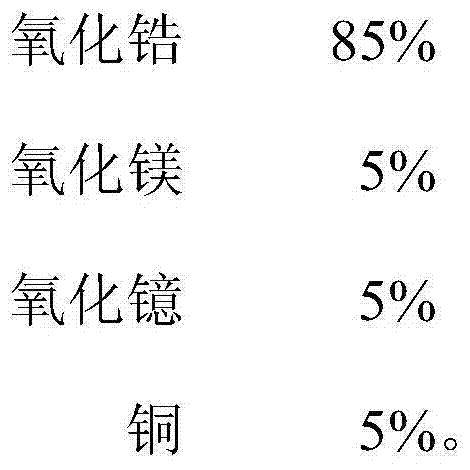

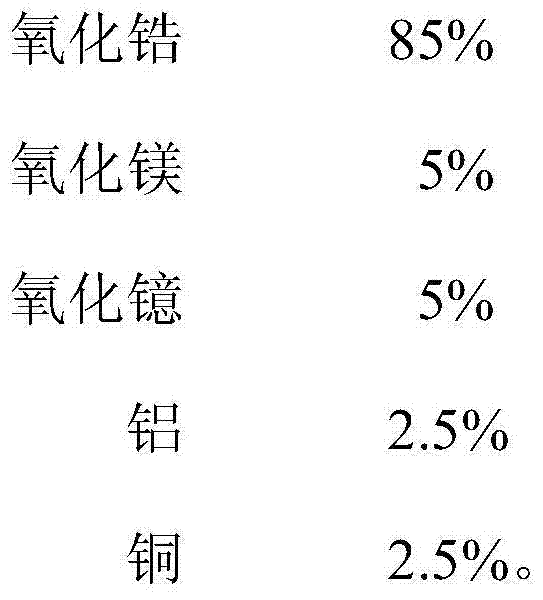

[0065] A zirconia ceramic center rod of the present invention comprises the following raw materials in mass percentage:

[0066] Zirconia 85%

[0068] Ytterbium Oxide 5%.

[0069] The zirconia in this embodiment is a mixture of cubic zirconia and nano zirconia in a mass ratio of 3:2.

[0070] A method for preparing a zirconia ceramic center rod, comprising the following processing steps:

[0071] Step A. Accurately weigh the raw materials according to the formula quantity and mix them uniformly for later use;

[0072] Step B. Put the uniformly mixed raw materials in step A into the mold using the combination of the vibration motor and the mold, so that the raw materials fill the mold, and the raw materials are tightly combined, and the opening of the mold is closed;

[0073] Step C. Insert the mold into the metal tube, then put the metal tube into the isostatic hydraulic press, and use the isostatic hydraulic press to compact the raw materials ...

Embodiment 3

[0081] A zirconia ceramic center rod of the present invention comprises the following raw materials in mass percentage:

[0082] Zirconia 90%

[0083] Magnesium Oxide 5%

[0084] Ytterbium Oxide 5%.

[0085] The zirconia in this embodiment is a mixture of cubic zirconia and nano zirconia at a mass ratio of 4:1.

[0086] A method for preparing a zirconia ceramic center rod, comprising the following processing steps:

[0087] Step A. Accurately weigh the raw materials according to the formula quantity and mix them uniformly for later use;

[0088] Step B. Put the uniformly mixed raw materials in step A into the mold using the combination of the vibration motor and the mold, so that the raw materials fill the mold, and the raw materials are tightly combined, and the opening of the mold is closed;

[0089] Step C. Insert the mold into the metal tube, then put the metal tube into the isostatic hydraulic press, and use the isostatic hydraulic press to compact the raw materials i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com