Coating used for electric automobile shell

A technology for electric vehicles and casings, applied in conductive coatings, fire-resistant coatings, etc., can solve problems such as poor waterproofness, corrosion, and poor adhesion, and achieve good sealing, excellent adhesion, and dense coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

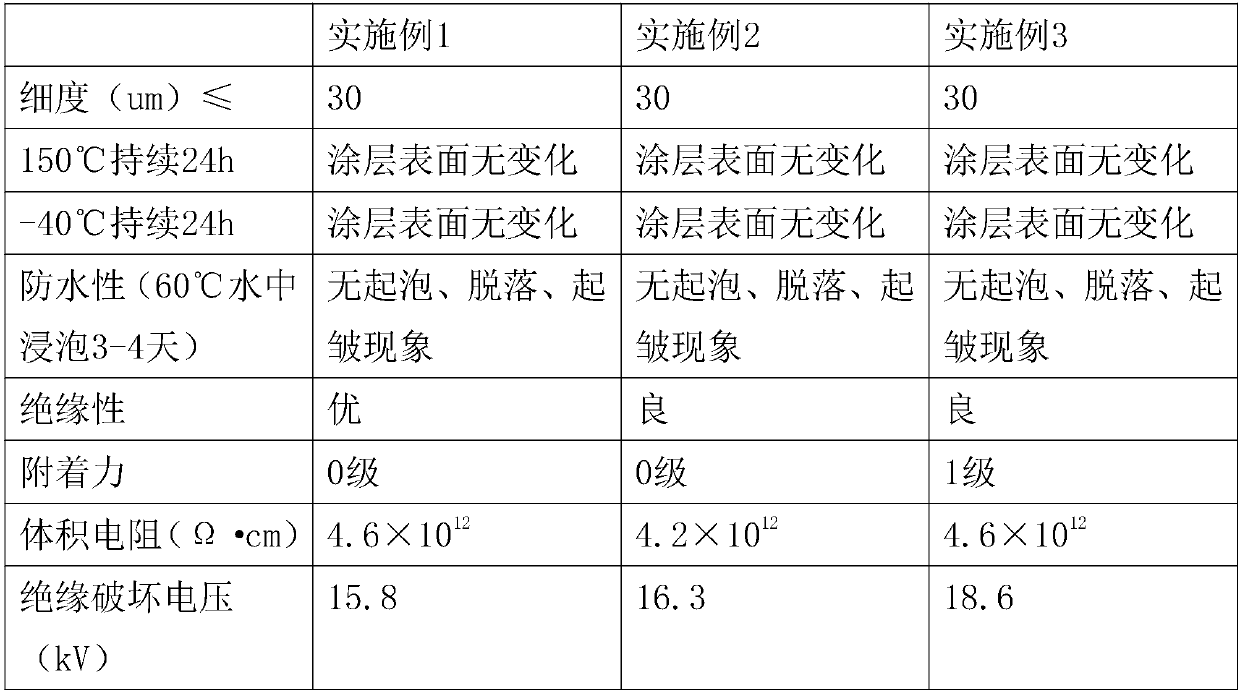

Examples

Embodiment 1

[0025] A coating for an electric vehicle shell, prepared from the following raw materials: 20 parts by weight of quartz powder, 20 parts by weight of vinyl acetate-vinyl chloride copolymer, 6 parts by weight of talcum powder, 6 parts by weight of ceramic microbeads, propylene glycol methyl ether acetic acid 6 parts by weight of ester, 6 parts by weight of nano-scale aluminum oxide, 4 parts by weight of stearic acid file, 4 parts by weight of aluminum-doped zinc oxide, 20 parts by weight of calcium stearate, 20 parts by weight of chlorophyll, 15-25 parts by weight of graphite, 6 parts by weight of guar gum ether, 6 parts by weight of chlorinated paraffin, 6 parts by weight of abaca fiber, 6 parts by weight of filler, 3 parts by weight of nonionic surfactant, 3 parts by weight of curing agent, 3 parts by weight of silicone modified polyurethane .

[0026] The filler is magnesium silicate.

[0027] The curing agent is a polyamide epoxy curing agent.

[0028] The nonionic surfac...

Embodiment 2

[0036] A coating for an electric vehicle shell, prepared from the following raw materials: 15 parts by weight of quartz powder, 15 parts by weight of vinyl acetate-vinyl chloride copolymer, 4 parts by weight of talcum powder, 4 parts by weight of ceramic microbeads, propylene glycol methyl ether acetic acid 4 parts by weight of ester, 4 parts by weight of nano-scale aluminum oxide, 3 parts by weight of stearic acid file, 3 parts by weight of aluminum-doped zinc oxide, 15 parts by weight of calcium stearate, 15 parts by weight of chlorophyll, 15 parts by weight of graphite, guar 5 parts by weight of gum ether, 5 parts by weight of chlorinated paraffin, 5 parts by weight of abaca fiber, 5 parts by weight of filler, 2 parts by weight of nonionic surfactant, 2 parts by weight of curing agent, and 2 parts by weight of silicone modified polyurethane.

[0037] The filler is an equal combination of magnesium silicate and china clay.

Embodiment 3

[0047] A coating for an electric vehicle shell, prepared from the following raw materials: 25 parts by weight of quartz powder, 25 parts by weight of vinyl acetate-vinyl chloride copolymer, 7 parts by weight of talcum powder, 7 parts by weight of ceramic microbeads, propylene glycol methyl ether acetic acid 7 parts by weight of ester, 7 parts by weight of nano-scale aluminum oxide, 5 parts by weight of stearic acid file, 5 parts by weight of aluminum-doped zinc oxide, 25 parts by weight of calcium stearate, 25 parts by weight of chlorophyll, 25 parts by weight of graphite, guar 7.5 parts by weight of gum ether, 7.5 parts by weight of chlorinated paraffin, 7.5 parts by weight of abaca fiber, 7.5 parts by weight of filler, 4 parts by weight of nonionic surfactant, 4 parts by weight of curing agent, and 4 parts by weight of silicone modified polyurethane.

[0048] The filler was a combination of equal amounts of magnesium silicate, china clay, silica and kaolin.

[0049] The curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com