Horizontal well drilling fluid for protecting coal bed gas reservoir

A technology for horizontal wells and coalbed methane, applied in the field of horizontal well drilling fluids, can solve the problems of solid phase blockage of fine coal dust, low salinity of clear water, hydration expansion of clay minerals, etc., to reduce blockage damage, strong interface activity, The effect of strong flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

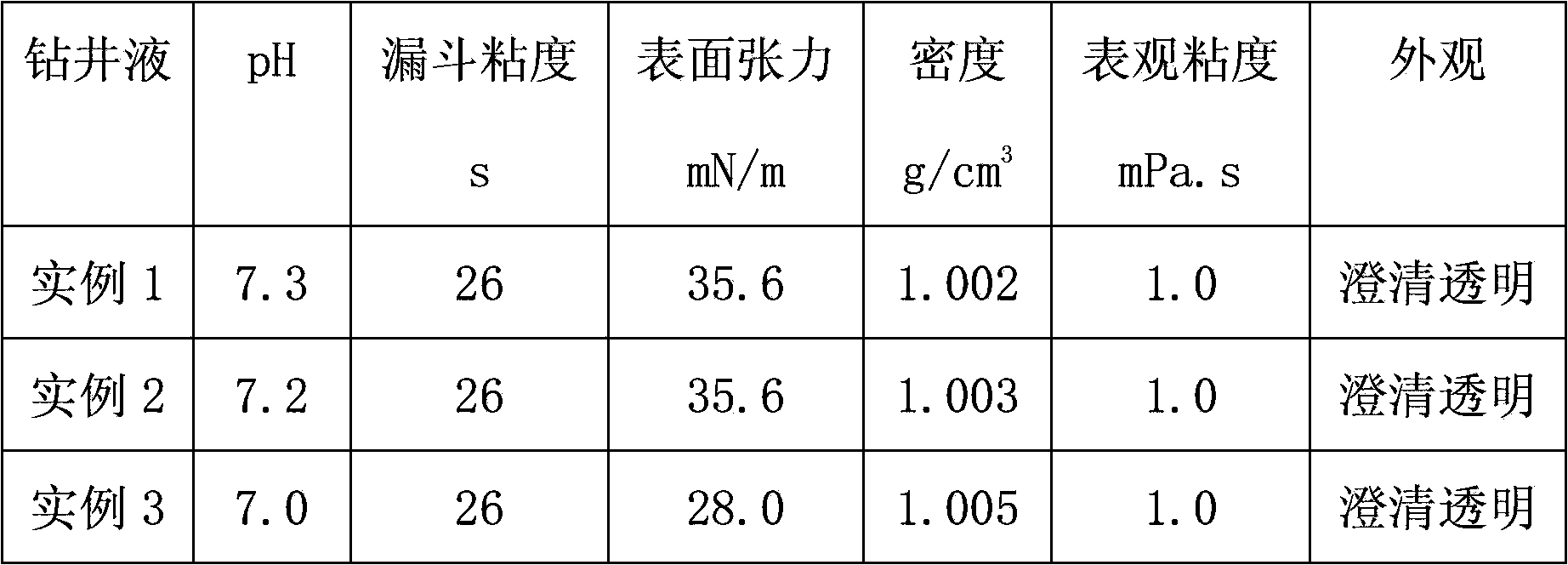

Embodiment 1

[0023] A kind of horizontal well drilling fluid for protecting the coalbed methane reservoir provided by the present invention, the weight percentage of each component is based on the weight of 100% water, and the percentage of each additive accounting for the weight of water is:

[0024] Anti-swelling agent: 0.2%; drainage aid: 0.05%; anti-scaling agent: 0.001%; flocculant: 0.2%.

[0025] Preparation method: Since the above-mentioned additives are small molecular or low molecular chemical substances, the dissolution is relatively fast and the preparation is simple. All the components are fully dissolved in water and then mixed.

Embodiment 2

[0027] A kind of horizontal well drilling fluid for protecting the coalbed methane reservoir provided by the present invention, the weight percentage of each component is based on the weight of 100% water, and the percentage of each additive accounting for the weight of water is:

[0028] Anti-swelling agent: 0.3%; drainage aid: 0.05%; anti-scaling agent: 0.003%; flocculant: 0.5%.

[0029] Preparation method: Since the above-mentioned additives are small molecular or low molecular chemical substances, the dissolution is relatively fast and the preparation is simple. All the components are fully dissolved in water and then mixed.

Embodiment 3

[0031] A kind of horizontal well drilling fluid for protecting the coalbed methane reservoir provided by the present invention, the weight percentage of each component is based on the weight of 100% water, and the percentage of each additive accounting for the weight of water is:

[0032] Anti-swelling agent: 0.5%; drainage aid: 0.1%; anti-scaling agent: 0.005%; flocculant: 0.4%.

[0033] Preparation method: Since the above-mentioned additives are small molecular or low molecular chemical substances, the dissolution is relatively fast and the preparation is simple. All the components are fully dissolved in water and then mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com