Dual-component silicone sealant for solar photovoltaic components and preparation method thereof

A solar photovoltaic and silicone sealant technology, applied in photovoltaic power generation, chemical instruments and methods, adhesives, etc., to achieve the effects of reducing loss, good adhesion and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

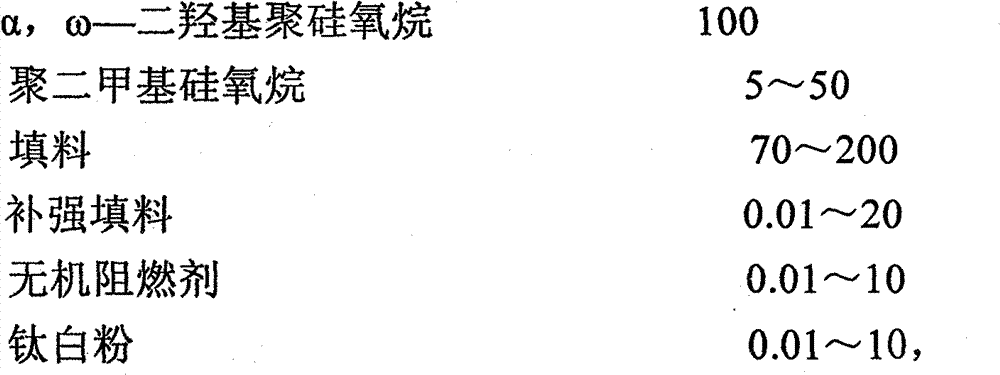

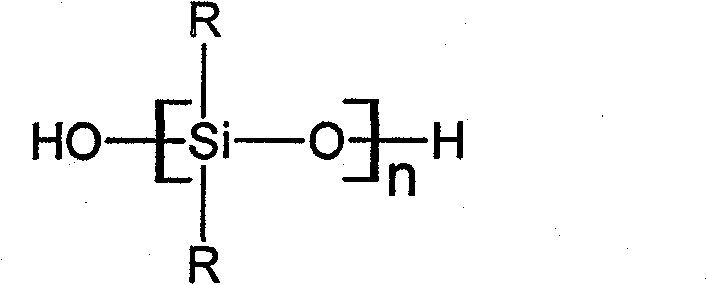

[0043] Add 100 parts of α, ω-dihydroxypolysiloxane, 5 parts of polydimethylsiloxane, 100 parts of active nano-calcium, 20 parts of fumed silica, 0.01 part of magnesium hydroxide, and 1 part of titanium dioxide into the In a high-speed mixer, dehydrate at a temperature of 90°C and a vacuum of 0.1 MPa for 4 hours, and obtain component A after cooling.

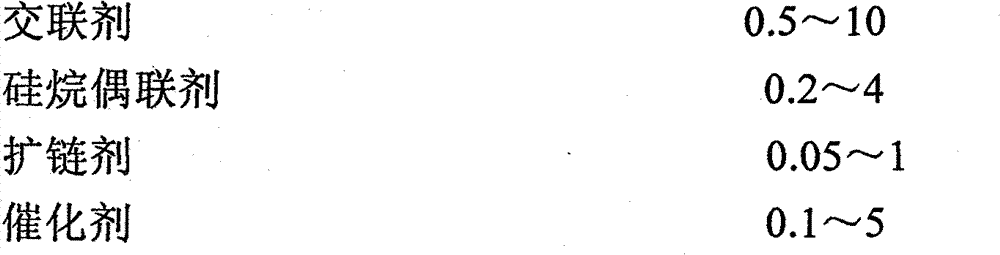

[0044] 0.5 parts of polytriethoxysiloxane, 1 part of 3-glycidylpropyltrimethoxysilane, 1 part of N-(β-aminoethyl)-α-aminopropyltrimethoxysilane, γ-ammonia Add 1 part of methyltriethoxysilane, 0.5 part of methylvinylbis(N-methylacetamido)silane, 2 parts of propyl titanate, and 1 part of dibutyltin dilaurate into a closed container, After mixing evenly, component B is prepared.

[0045] Mix the above-mentioned components A and B according to the weight ratio A:B=100:8, and defoam for 5 minutes at a vacuum degree of 0.1Mpa to obtain a two-component silicone sealant. The product performance test results are shown in Table 1.

Embodiment 2

[0047] Add 100 parts of α, ω-dihydroxy polysiloxane, 30 parts of polydimethylsiloxane, 70 parts of silicon micropowder, 10 parts of precipitated silica, 10 parts of aluminum hydroxide, and 10 parts of titanium dioxide into the high-speed In a mixer, dehydrate at a temperature of 120°C and a vacuum of 0.06MPa for 3 hours, and obtain component A after cooling.

[0048] 8 parts of methyl orthosilicate, 0.2 parts of N-(β-aminoethyl)-α-aminopropyltrimethoxysilane, 1 part of dimethylbis(N-methylacetamido)silane, titanate Add 3 parts of chelate compound and 2 parts of dioctyltin dilaurate into an airtight container, and mix well to prepare component B.

[0049] The above-mentioned components A and B are mixed uniformly according to the weight ratio A:B=100:10, and the two-component silicone sealant is obtained after defoaming at a vacuum degree of 0.08Mpa for 10 minutes. The product performance test results are shown in Table 1.

Embodiment 3

[0051] 100 parts of α, ω-dihydroxypolysiloxane, 50 parts of polydimethylsiloxane, 110 parts of silicon powder, 90 parts of superfine calcium carbonate, 1 part of zinc borate, and 0.01 parts of surface-modified fumed silica Add 0.01 part of titanium dioxide into a high-speed mixer, dehydrate at a temperature of 150°C and a vacuum of 0.09Mpa for 0.5 hours, and obtain component A after cooling.

[0052] 10 parts of ethyl orthosilicate, 0.5 parts of 3-glycidylpropyltrimethoxysilane, 1 part of γ-methacryloxypropyltrimethoxysilane, N-(β-aminoethyl)-α -2 parts of aminopropyltrimethoxysilane, 1.5 parts of γ-aminomethyltriethoxysilane, 0.05 part of methylvinylbis(N-methylacetamido)silane, 0.1 part of dibutyltin diacetate Add it into an airtight container and mix well to get component B.

[0053] The above-mentioned components A and B are mixed uniformly according to the weight ratio A:B=100:15, and the two-component silicone sealant is obtained after defoaming at a vacuum degree of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com