Hydration-resistant magnesia chrome castable for nonferrous metallurgical furnaces and preparation method thereof

A technology for waterproofing and castables, applied in the field of non-ferrous metallurgical refractories, can solve the problems of low strength and short shelf life, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Further, the present invention also provides a preparation method of the above-mentioned waterproof magnesium-chromium castable for non-ferrous metallurgical furnaces, the preparation method comprising the following steps:

[0022] 1) Breaking the magnesia-chrome block material to prepare magnesia-chrome pellets, and then classifying the pellets into magnesia-chrome sands with a particle size of 5-8mm, 3-5mm, 1-3mm and 0-1mm for later use;

[0023] 2) Select a part of magnesia-chromium sand with a particle size of 0-1 mm to prepare magnesia-chrome fine powder, add stearic acid accounting for 0.5-2% of the mass fraction, and grind it with a ball mill or Raymond machine until the particle size is 160-200 mesh;

[0024] 3) Take 15 parts of magnesia chrome sand with a particle size of 5-8 mm, 10 parts of magnesia chrome sand with a particle size of 3-5 mm, 10-15 parts of magnesia chrome sand with a particle size of 1-3 mm, magnesia-chrome fine powder and a particle size of ...

Embodiment 1

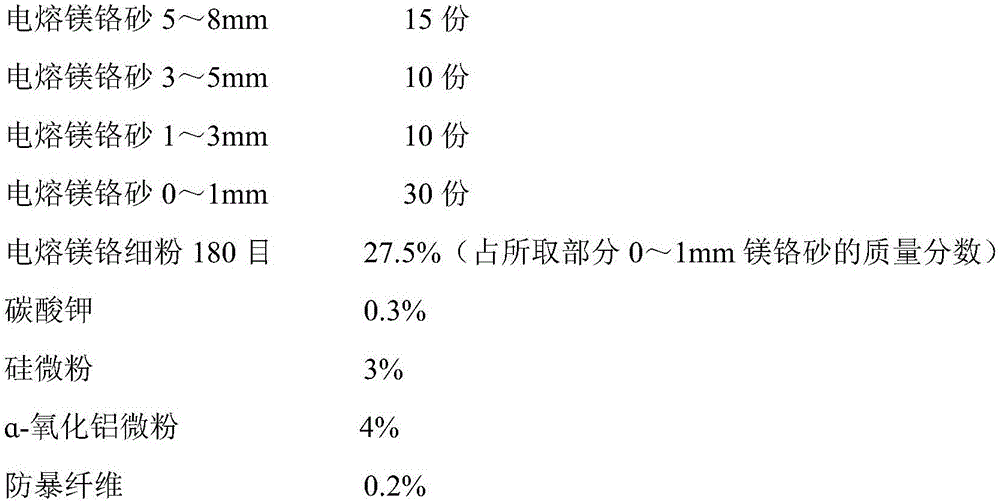

[0031] The fused magnesia-chrome block material is crushed by a crusher and then classified into magnesia-chrome sands with particle sizes of 5-8mm, 3-5mm, 1-3mm and 0-1mm, and 0.5% stearin is added to some 0-1mm magnesia-chrome sands The acid is ground into a 180-mesh fine powder by a ball mill for later use; the special waterproof magnesium-chromium castable for non-ferrous metallurgical kilns is made according to the following mass ratio:

[0032]

[0033] Put the components except potassium carbonate in a blender and stir them evenly, then pack them into 25 kg packaging bags. The potassium carbonate in the package is first dissolved in an appropriate amount of tap water, stirred together with the mixture in the large packaging bag, then poured into the part to be poured, and shaken to shape.

Embodiment 2

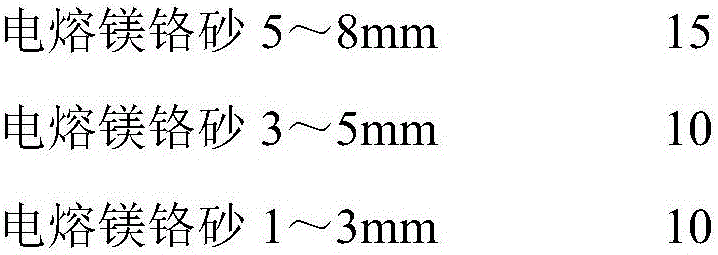

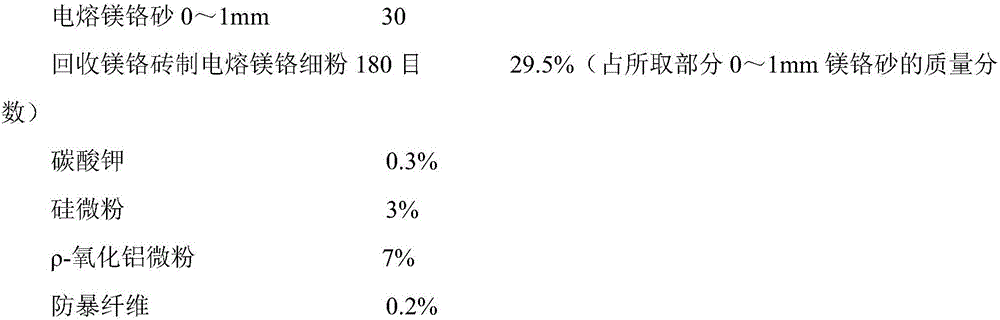

[0035]Recycled magnesia-chrome bricks are crushed by a crusher and classified into 5-8mm, 3-5mm, 1-3mm and 0-1mm granular magnesia-chrome sand, and a part of 0-1mm magnesia-chrome sand is selected and added with 2% stearic acid and ground by a ball mill. 180-mesh fine powder for use; special waterproof magnesium-chromium castable for non-ferrous metallurgical furnaces is made according to the following mass ratio:

[0036]

[0037]

[0038] Put the components except potassium carbonate in a blender and stir them evenly, then put them into 25 kg packaging bags. Potassium carbonate is packaged in a separate small package and packed together. The potassium carbonate in the package is first dissolved in an appropriate amount of tap water, stirred together with the mixture in the large packaging bag, then poured into the part to be poured, and shaken to shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com