Car first template exemplar shaping method

A molding method and prototype technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of affecting the supporting strength of the prototype, insufficient supporting strength of the prototype, vibration and loosening of the gypsum layer, etc., to reduce costs and improve Adhesion performance, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

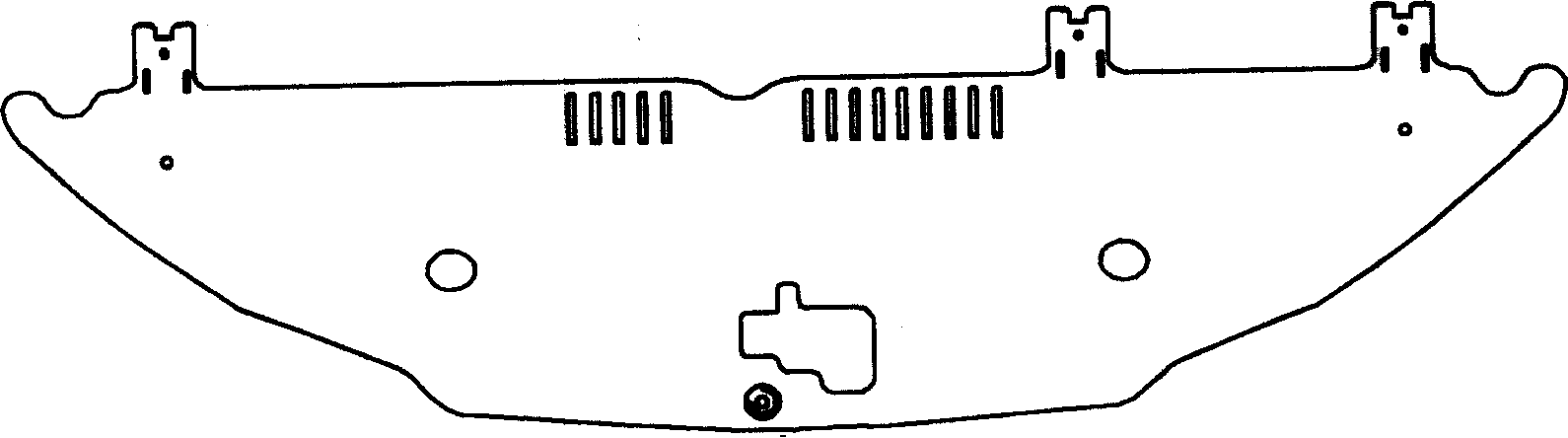

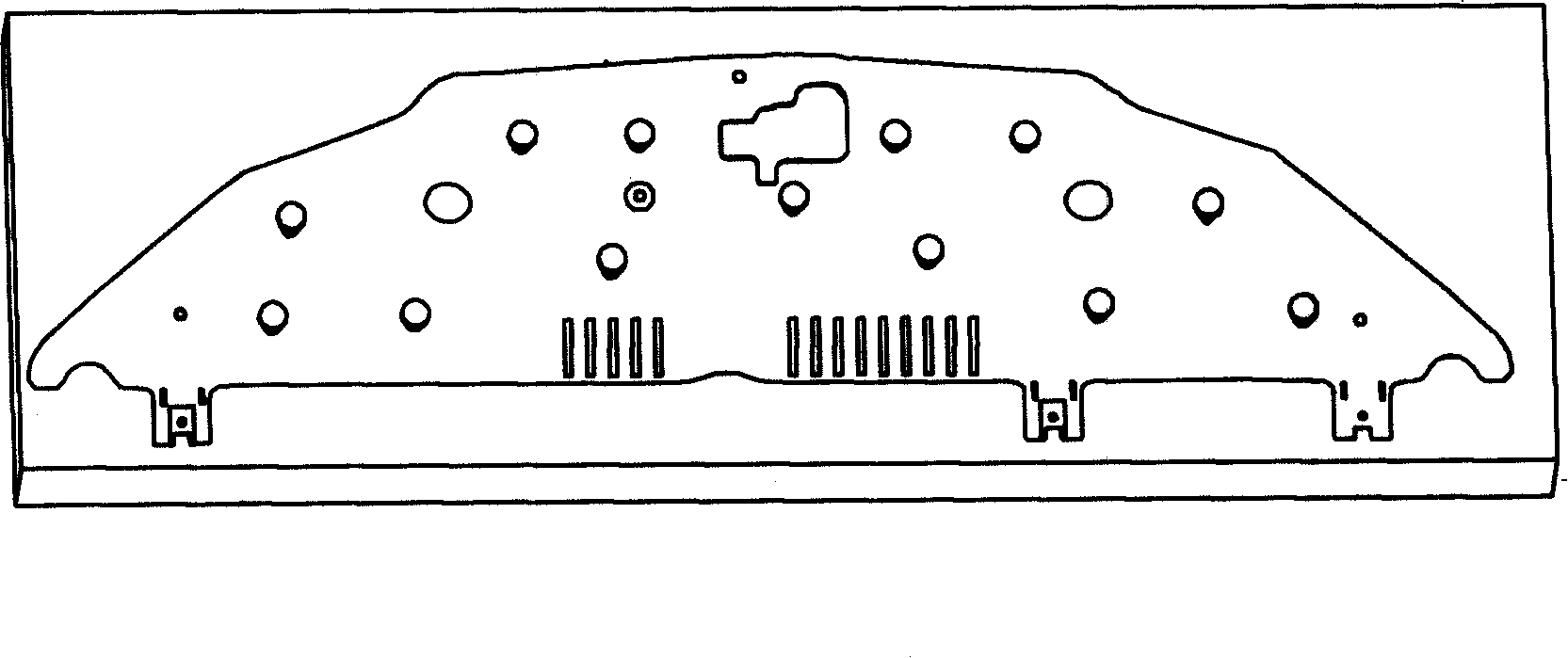

[0029] for processing figure 1 The shown 1310mm × 340mm × 3mm engine compartment cover front trim adopts an embodiment of the method of the present invention, and the method includes the following steps:

[0030] a. First cut the blank to form the workpiece, and process the back of the sample on the workpiece;

[0031] b. Bond a plurality of formed T-shaped round piles in the processing and forming area on the back of the sample, the vertical end of the T-shaped round pile is bonded to the forming area of the blank, and the upper end surface of the horizontal part corresponds to the back of the blank;

[0032] c. Fill the remaining area with gypsum and scrape it off;

[0033] d. The front of the blank after the gypsum is shaped;

[0034] e. Remove the T-shaped round pile and plaster;

[0035] The material of the blank in step a can be CNC machining materials such as ABS, POM, PC, PA, metal, etc., preferably ABS.

[0036] The T-shaped round pile in the step b is bonded wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com