Ball-head cuter processing shaft vector smoothing method based on BA type five-axis numerically-controlled machine tool

A tool axis vector and CNC machine tool technology, which is applied to the tool axis vector smoothing of five-axis CNC machine tools. Fluctuation and other problems, to achieve smooth and smooth motion, avoid sudden changes, reduce angular velocity and angular acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

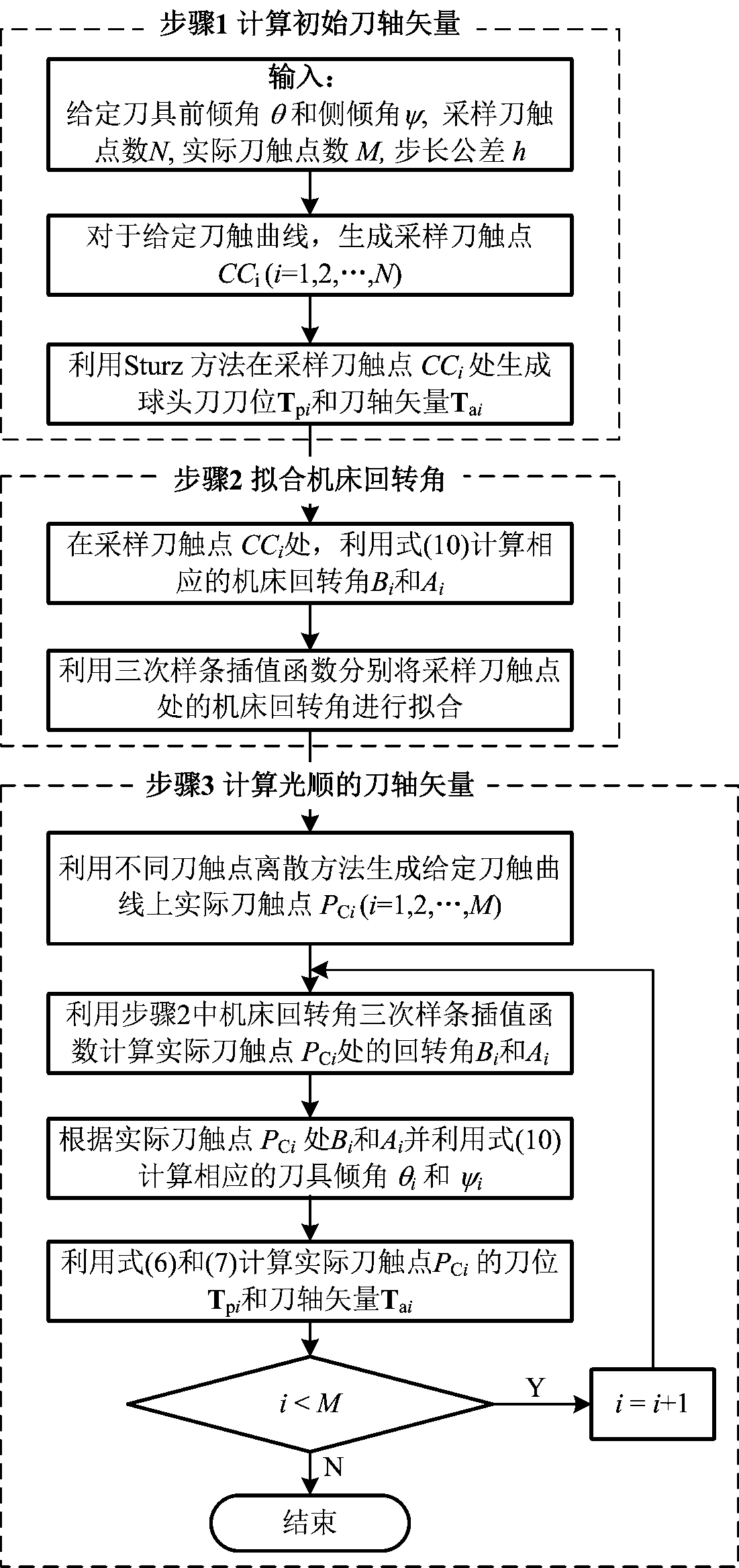

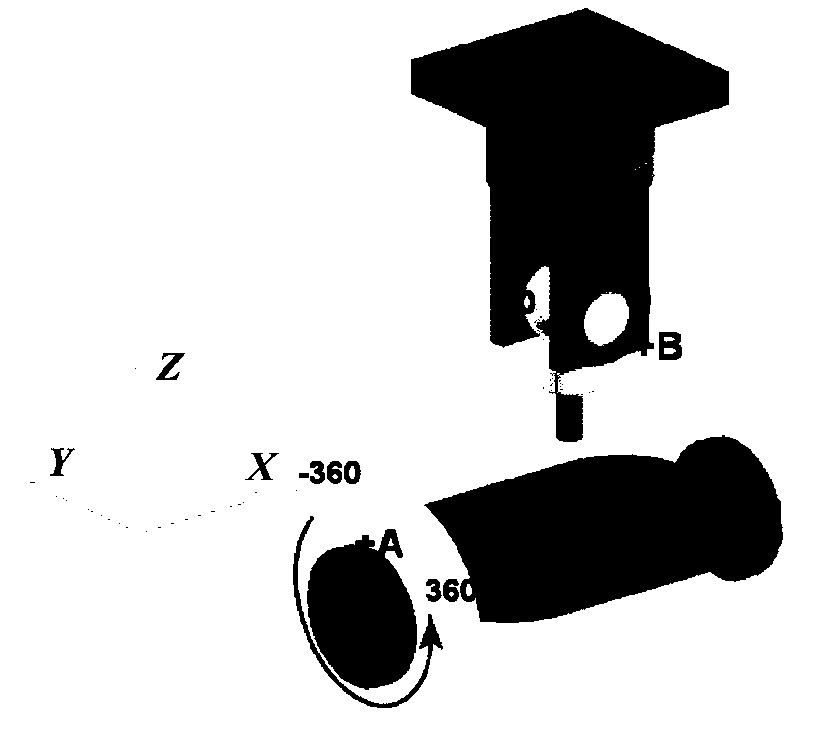

[0046] The present invention is based on a BA-type five-axis CNC machine tool ball-end cutter processing tool axis vector smoothing method, the basic process of which is as follows figure 1 As shown, its preferred specific implementation method includes:

[0047] Step A, establishing the relational equation between the tool axis vector of the ball-end cutter and the design variable of the cutter position. Described step A specifically is:

[0048] (1) The relationship equation between the tool axis vector of the ball head cutter and the design variable of the cutter position in the local coordinate system

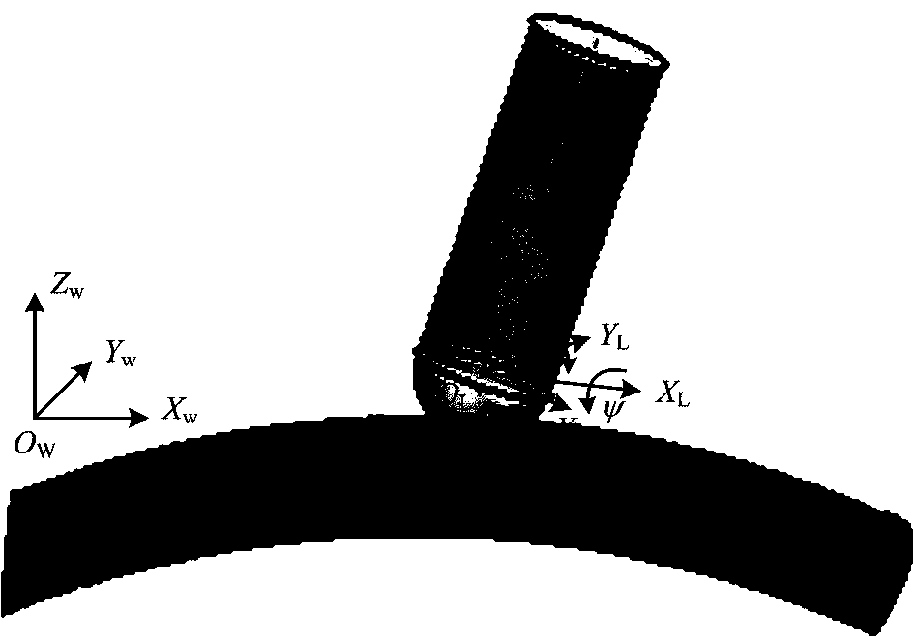

[0049] like figure 1 As shown, let the ball-end cutter process the complex surface S: r(u,v), P cc (u cc ,v cc ) is any point on the surface, n cc is the unit normal vector of the point, O w x w Y w Z w is the workpiece coordinate system. Let r be the radius of the ball nose cutter, O L is the origin of the local coordinate system, in and point O L and P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com