Cutting machine special for plastic welding rods

A technology of cutting machine and welding rod, which is applied in the direction of metal processing, etc., can solve the problems of high equipment cost of flying knife cutting machine, difficulty in obtaining market recognition, and high maintenance cost, so as to improve production efficiency and economic efficiency, compact structure, The effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

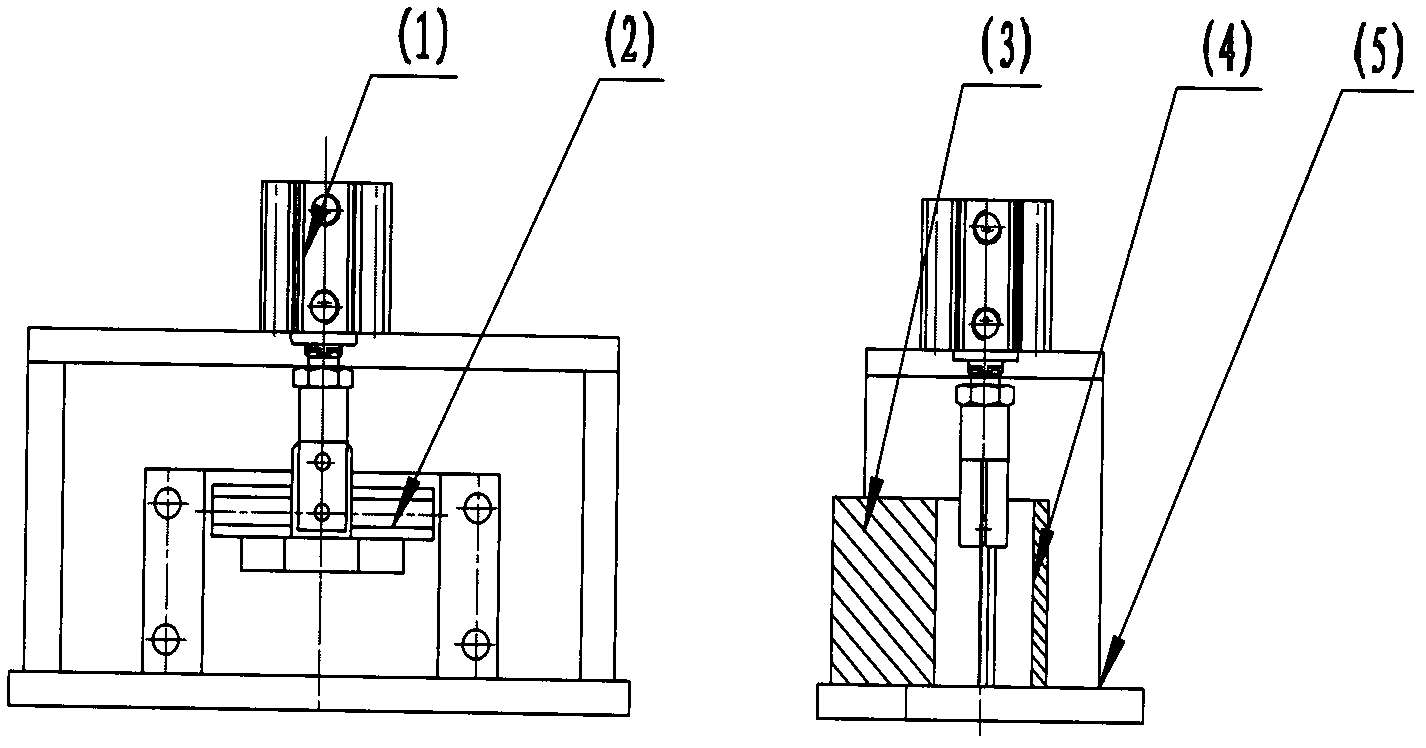

[0010] A special cutting machine for plastic welding rods consists of four parts: (1) cutting cylinder, (2) cutting blade, (3) cutting fixed knife, (4) cutting guiding device and (5) frame. The special cutting blade for plastic welding rod is made of alloy tool steel. It is a double-edged cutting type with upper and lower edges. The cutting cylinder only needs one action to complete the cutting action. The cylinder does not need to be reset, which improves the cutting speed and efficiency, and has a long service life of the cutting blade. The advantages of long, smooth incision and no burrs; when starting to cut, (1) the cutting cylinder moves first, pushing the (2) cutting blade to move under the guidance of the (4) cutting guide device, when (2) the cutting blade and (3) ) When the cutting knife is in contact, the plastic welding rod can be cut off. After cutting (1) the cutting cylinder does not need to be reset, because (2) the cutting blade is designed with double edges. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com