Milling cutter replacement device

A technology for milling cutters and milling cutter shafts, which is applied to milling cutters, positioning devices, milling machine equipment, etc., can solve the problems of affecting work efficiency, increasing radiation hazards for operators, and numerous steps, so as to improve work efficiency, reduce radiation hazards, The effect of reducing the chance of entering the hot chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

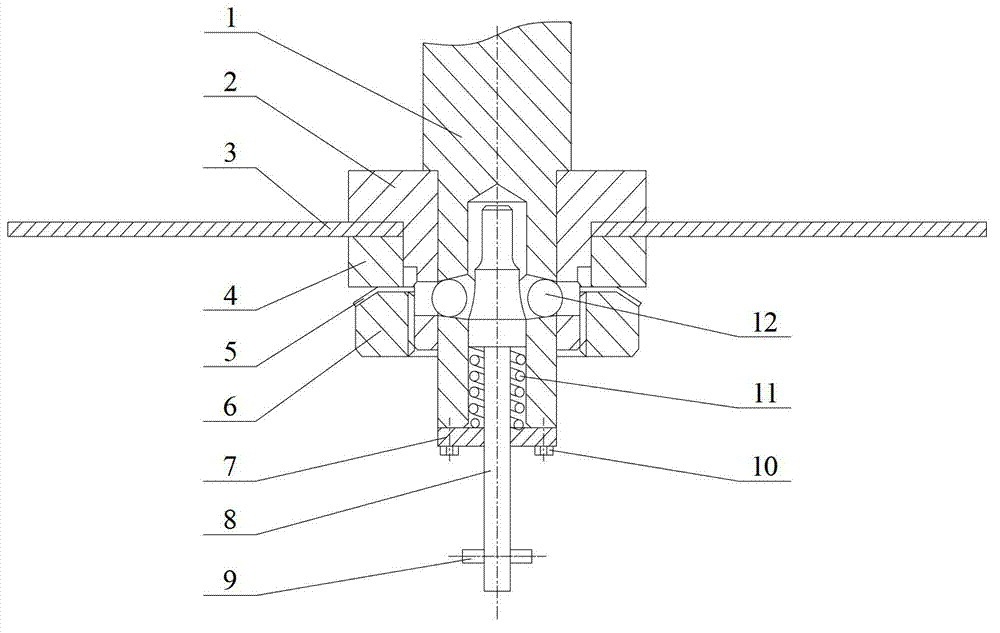

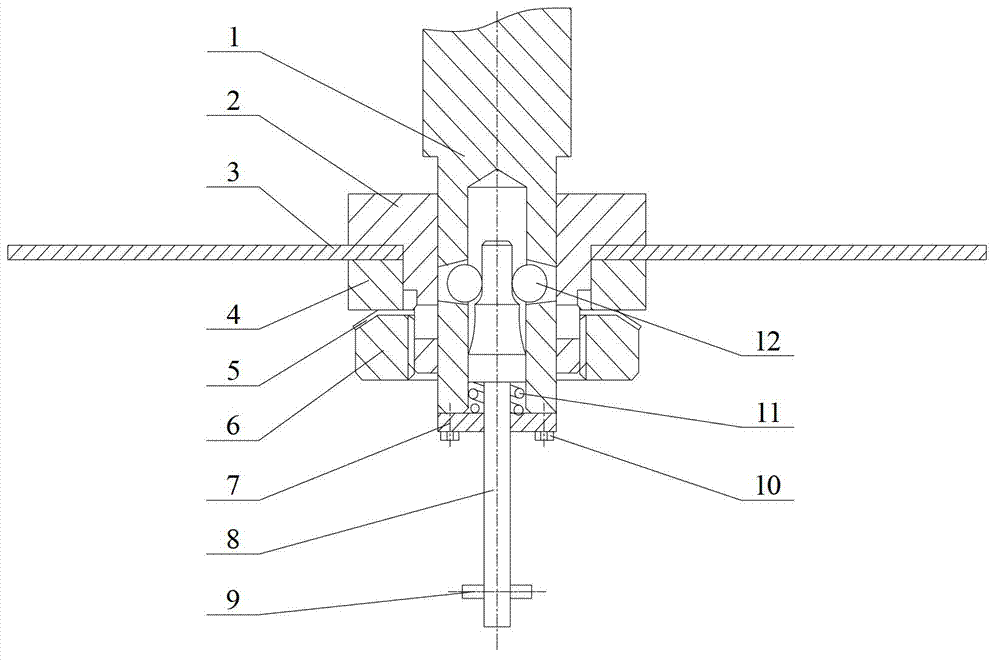

[0023] According to the milling cutter replacement device of the present invention, a plurality of first through holes are arranged on the milling cutter shaft along the radial direction, and the milling cutter seat on which the milling cutter is clamped is provided with holes corresponding to the first through holes. The second through hole, through the combination and separation of the steel ball and the first and second through holes, completes the fixing and loosening of the milling cutter seat and the milling cutter shaft, thereby realizing the rapid replacement of the milling cutter. The invention has a simple structure, can use the manipulator in the hot chamber to perform long-distance replacement, minimizes the probability of personnel entering the hot chamber, reduces radiation hazards, and improves work efficiency.

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com