Visual two-arm edge oiling machine

An oil edge machine, oil edge technology, applied in the trimming of leather edges, small raw hides/large raw hides/leather/fur mechanical processing, small raw hides/large raw hides/leather/fur processing, etc. Product aesthetics and other issues, to achieve efficient and accurate adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

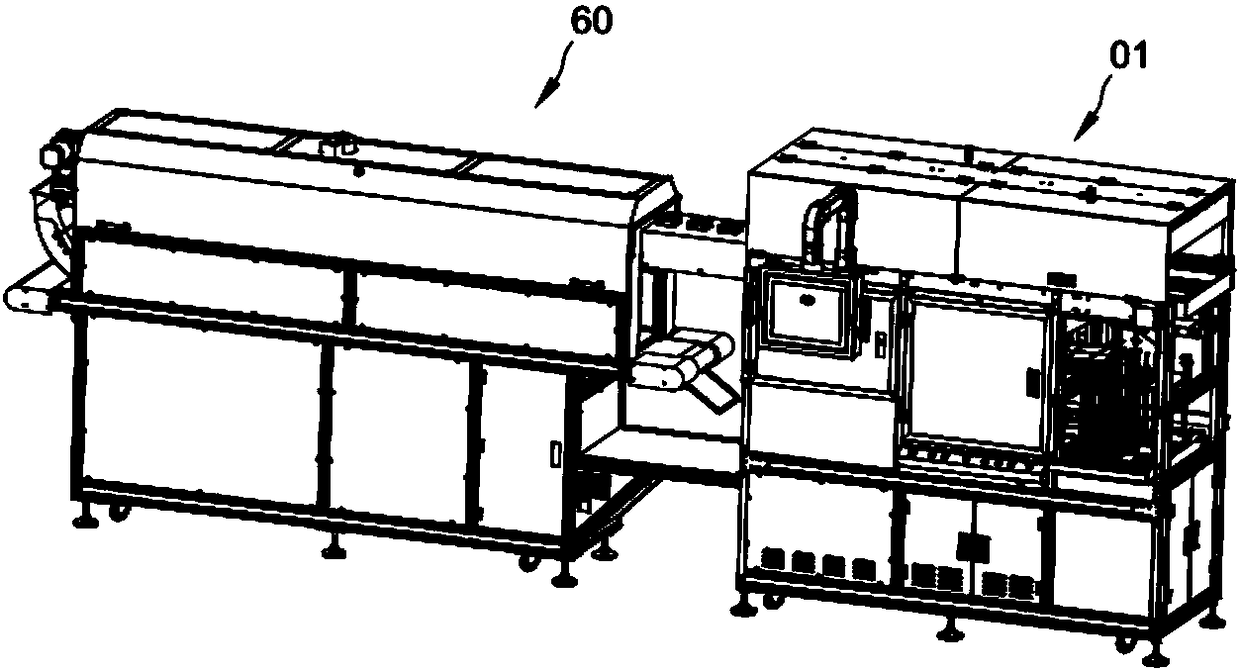

[0034] Such as figure 1 , a visual dual-arm oil edge machine, including a leather oil edge system 01 and a drying mechanism 60.

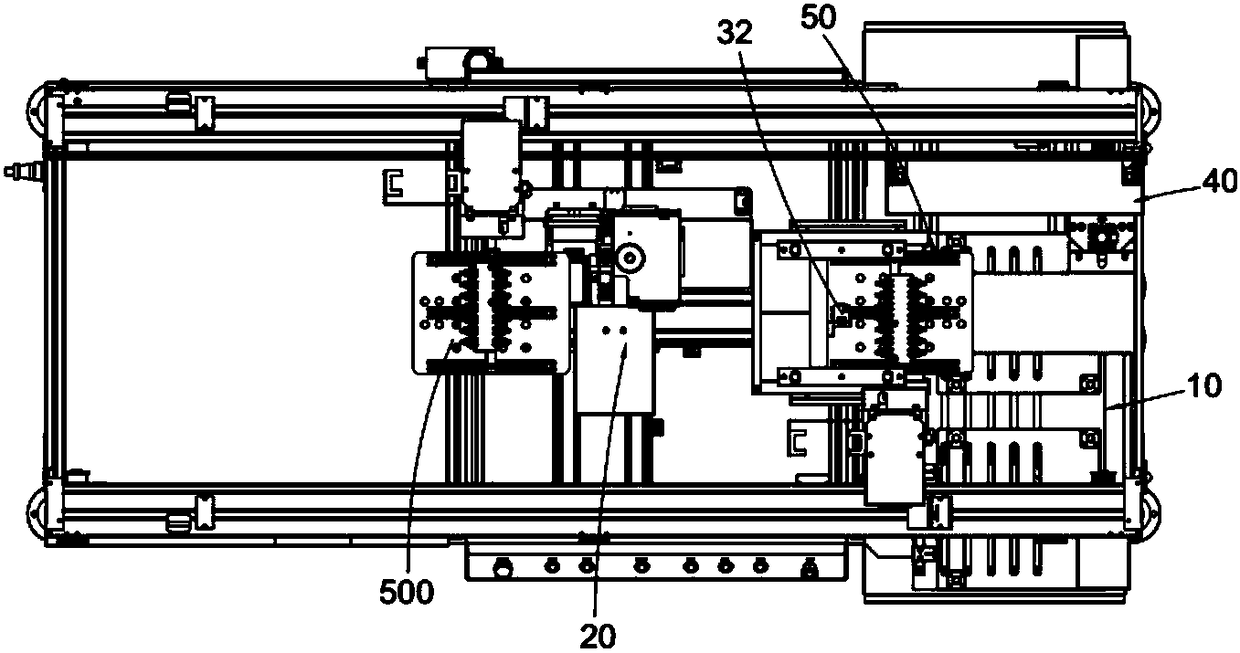

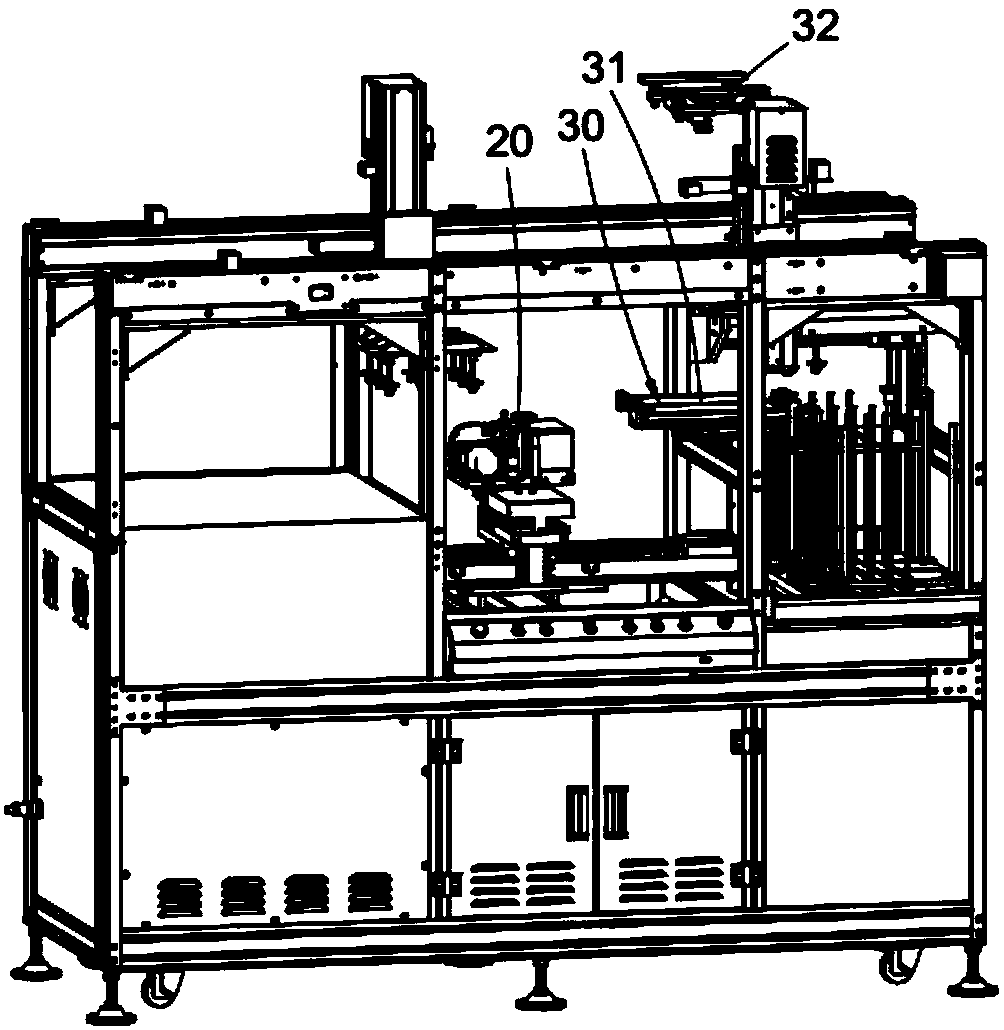

[0035] combine Figure 2 to Figure 4 , The leather oil edge system 01 includes a feeding mechanism 10, an oil edge mechanism 20, and a leather conveying system that goes back and forth between the feeding mechanism and the oil edge mechanism.

[0036] Such as Figure 5 The feeding mechanism 10 includes two laterally adjacent feeding sub-mechanisms 11, the feeding mechanism is installed on the feeding mechanism driving device 12, and the feeding mechanism driving device drives the feeding mechanism to move laterally.

[0037] The first material feeding sub-mechanism of the feeding mechanism stacks leather materials up and down. Driven by the driving device of the feeding mechanism, the first material feeding sub-mechanism comes to the bottom of the leather material conveying system, and the leather material conveying system puts the leather materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com