Automatic edge scraping device for leather wallet production

A wallet, automatic technology, applied in the trimming of leather edges, small raw hides/large raw hides/leather/fur processing, small raw hides/large raw hides/leather/fur mechanical processing, etc. problems, to achieve the effect of saving consumption and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

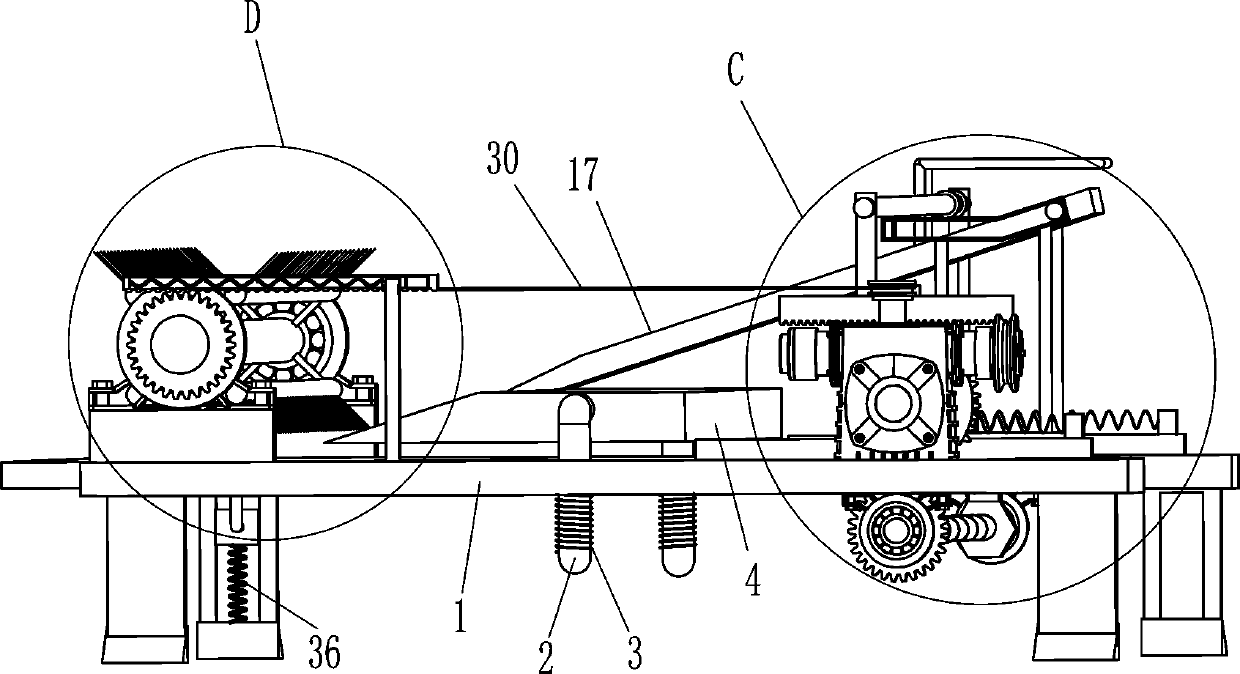

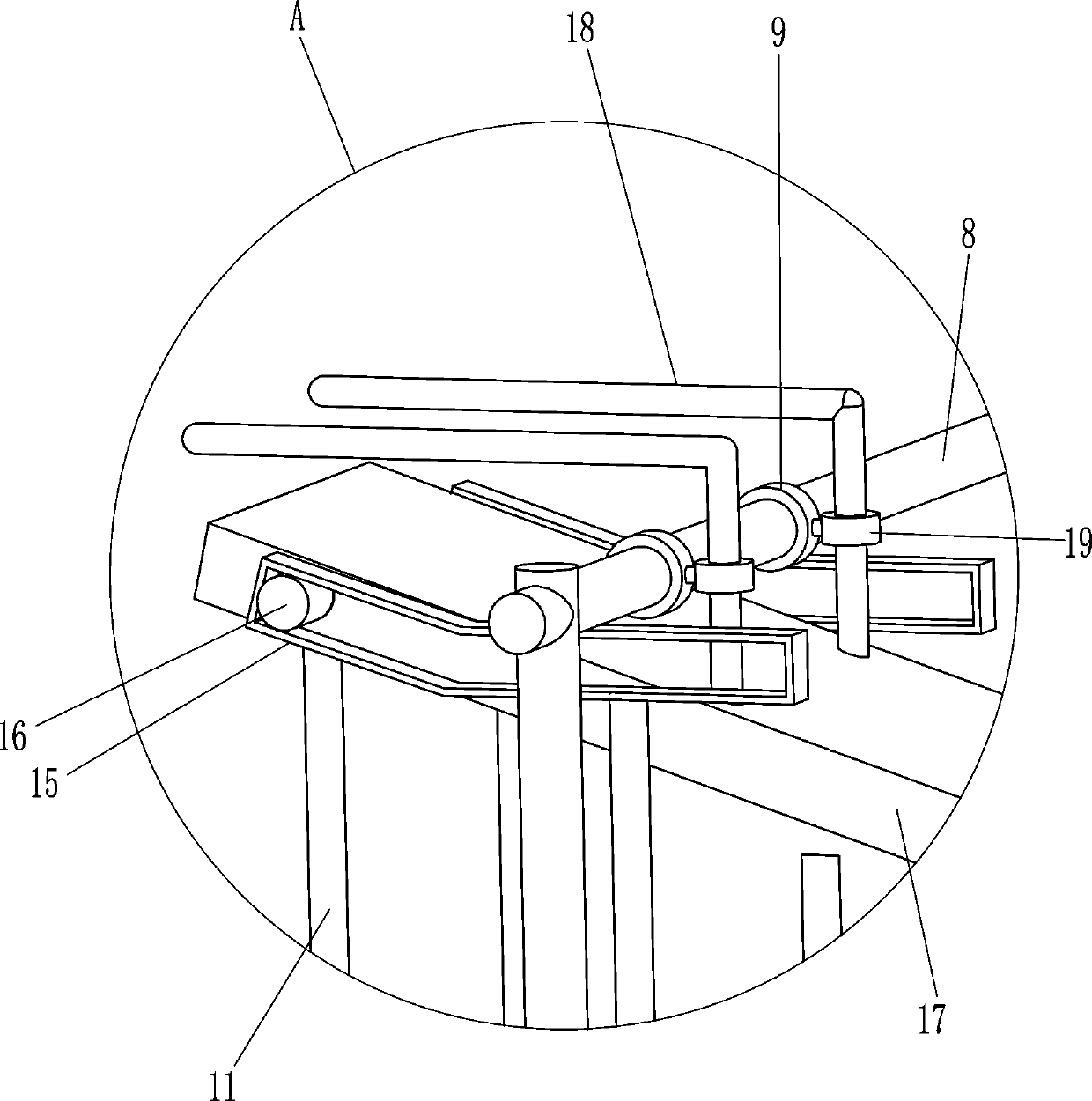

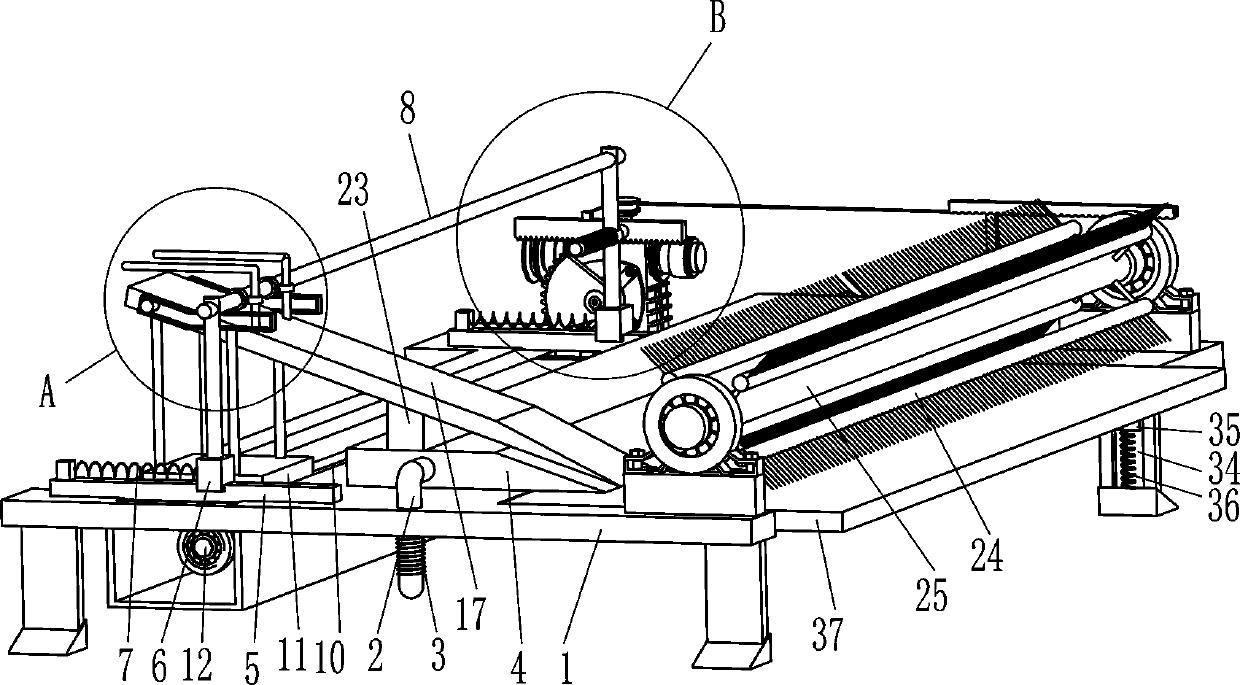

[0023] refer to figure 1 , 2 , 3, 4 and 5, an automatic shoveling device for leather wallet production, including a support plate 1, a fixed part, a sliding shoveling part, a cleaning part and a transmission part, and the middle of the support plate 1 top is provided with a lifting method Compressed fixed parts, the left side of the top of the support plate 1 is provided with a sliding shoveling part for shoveling by sliding. Parts, the sliding shoveling part is provided with a transmission part that performs intermittent transmission by sliding, and the transmission part cooperates with the sliding shoveling part.

[0024] refer to figure 1 , the fixed part includes an L-shaped guide rod 2, a first spring 3 and a pressure plate 4, and the front and rear sides of the top of the support plate 1 are slidingly provided with an L-shaped guide rod 2, and the L-shaped guide rod 2 is connected to the support plate 1 There is a first spring 3, and the first spring 3 is sleeved on t...

Embodiment 2

[0034] On the basis of embodiment 1, refer to image 3 , 4 And 6, in order to make the device more convenient and practical, it also includes a pulley 29, a pull wire 30, a second slider 31, a second rack 32, a fourth spring 321 and a second full gear 33, and the top of the reduction motor 21 is fixed by screws There is a pulley 29, the first tooth bar 27 rear side is connected with a backguy 30, the back side of the top of the support plate 1 is connected with a second slider 31 through a pole, the second slider 31 is slidably provided with a second tooth bar 32, the second A fourth spring 321 is connected between the second rack 32 and the second slider 31, the pull wire 30 is connected to the second rack 32 around the pulley 29, the rear side of the rotating shaft 25 is provided with a second full gear 33, and the second full gear 33 meshes with the second rack 32.

[0035] refer to figure 1 , also includes a third slider 35, a fifth spring 36 and a placement plate 37, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com