Novel automatic edge dyeing machine and edge dyeing method thereof

An oil edge machine, automatic technology, applied in the trimming of the edge of leather goods, small raw leather/big raw leather/leather/fur mechanical treatment, small raw leather/big raw leather/leather/fur treatment, etc., can solve the problems affecting product qualification rate, Difficult to ensure smoothness, uneven oiling and other problems, to achieve the effect of accurate and reliable positioning, sensitive response and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

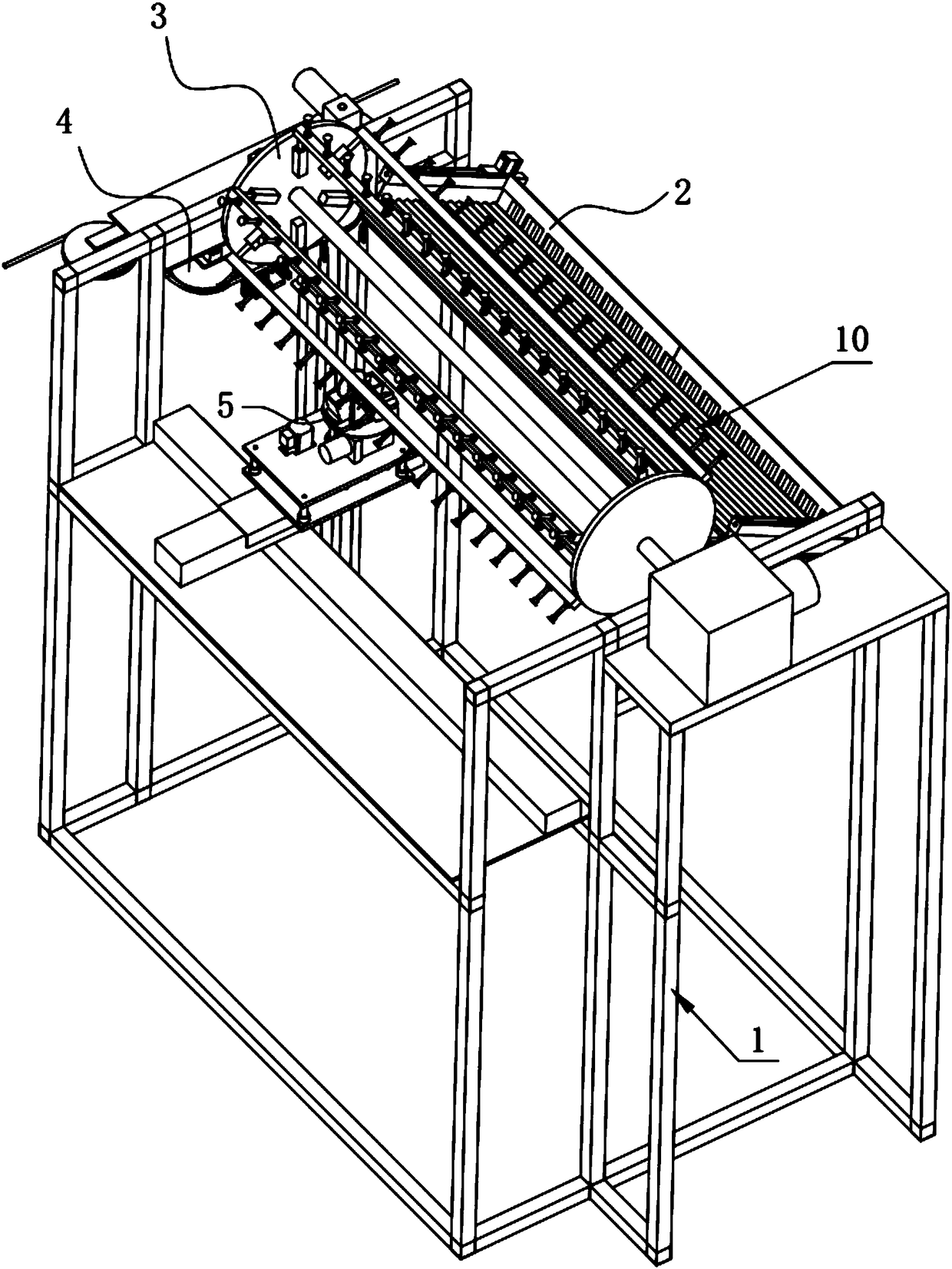

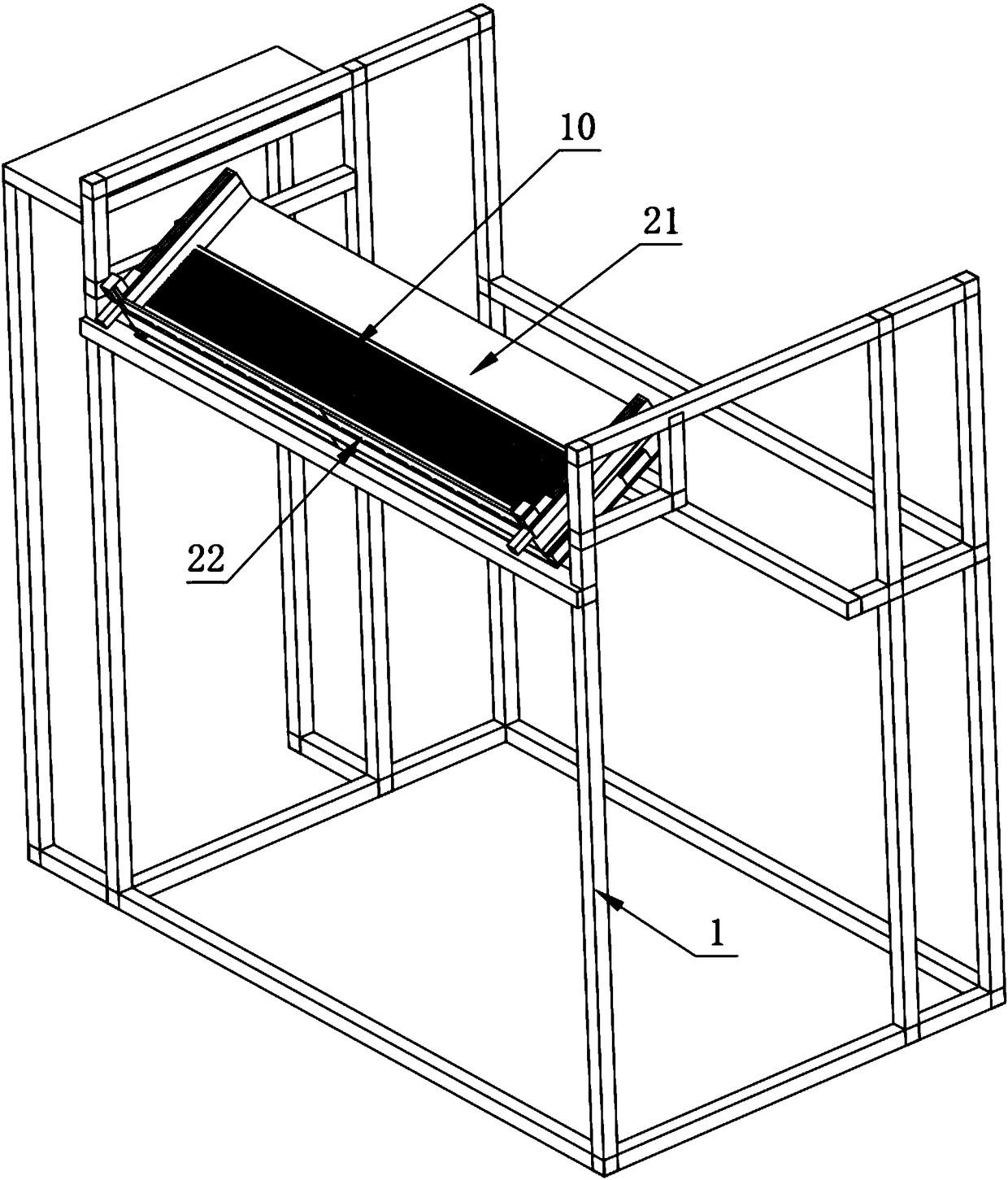

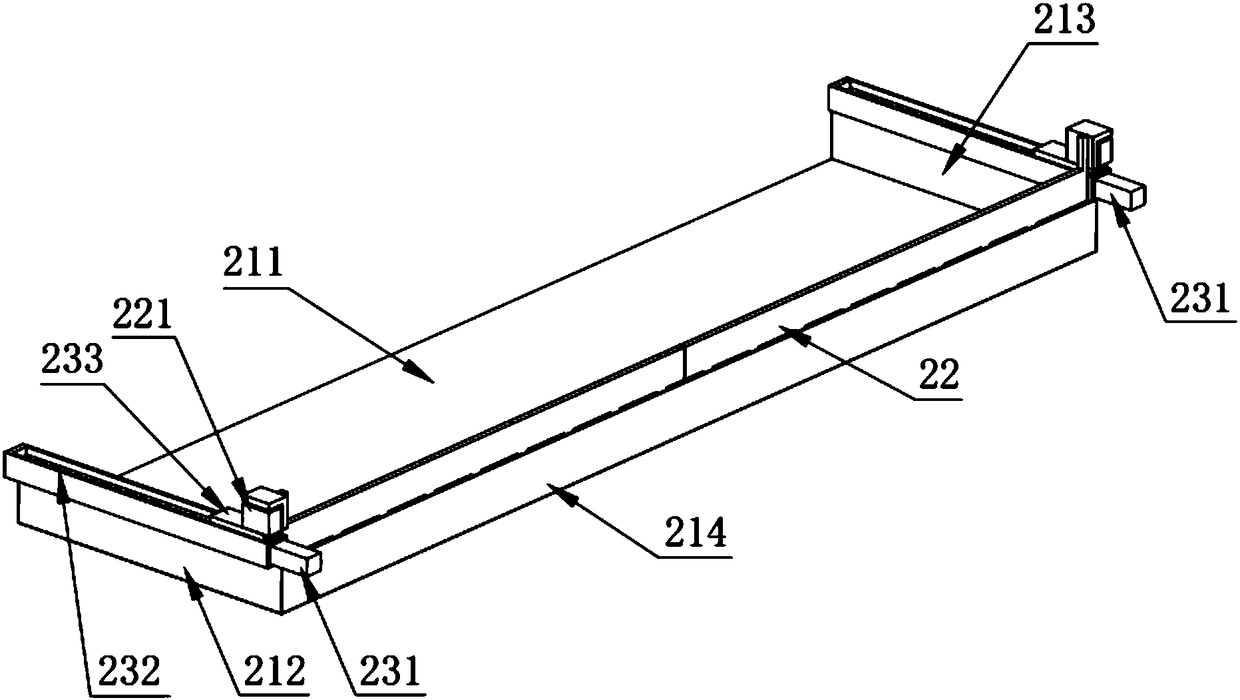

[0046] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 14 ,

[0047] A new type of automatic oil edge machine, comprising a frame 1, on which a feeding mechanism 2, a material retrieving mechanism 3, an oil edge mechanism and a material retrieving and drying mechanism 4 are arranged. On the frame 1, a charging rack 21 for placing the leather material 10 to be oiled, and a feeding mechanism is installed on the charging rack 21;

[0048] The material retrieving mechanism includes a rotating disk mounted on the frame 1, the rotating disk is provided with several retrieving rods 36, and several retrieving nozzles 37 for absorbing leather materials are installed on the retrieving rod 36;

[0049] The oil edge mechanism includes an oil edge machine head 5 that is arranged on the frame, and the oil edge machine head is provided with a drive motor that can drive it to rotate along the leather...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com