Flanging press system and flanging press method thereof

A technology of edge pressing and pressing plate, applied in the trimming of leather edges, mechanical processing of small raw hides/large raw hides/leather/fur, small raw hides/large raw hides/leather/fur processing, etc. Long time and other problems to achieve the effect of reducing processing time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

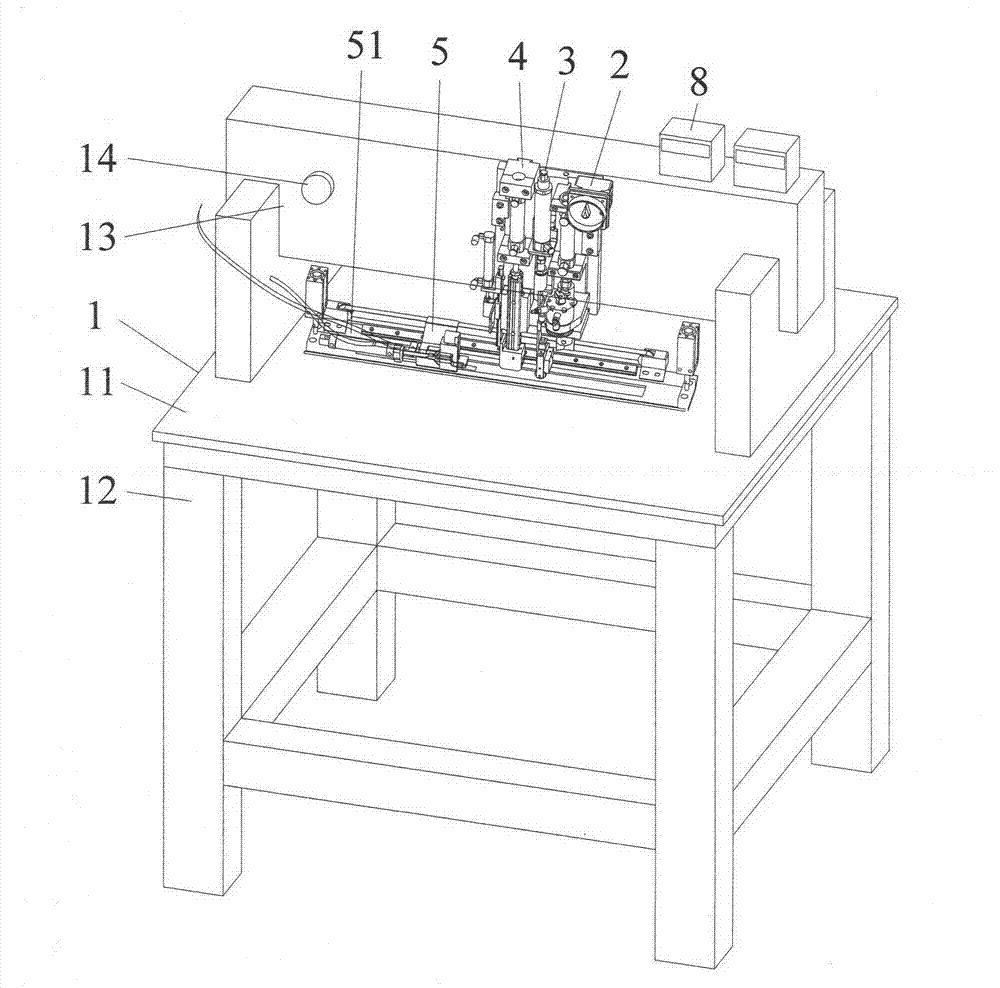

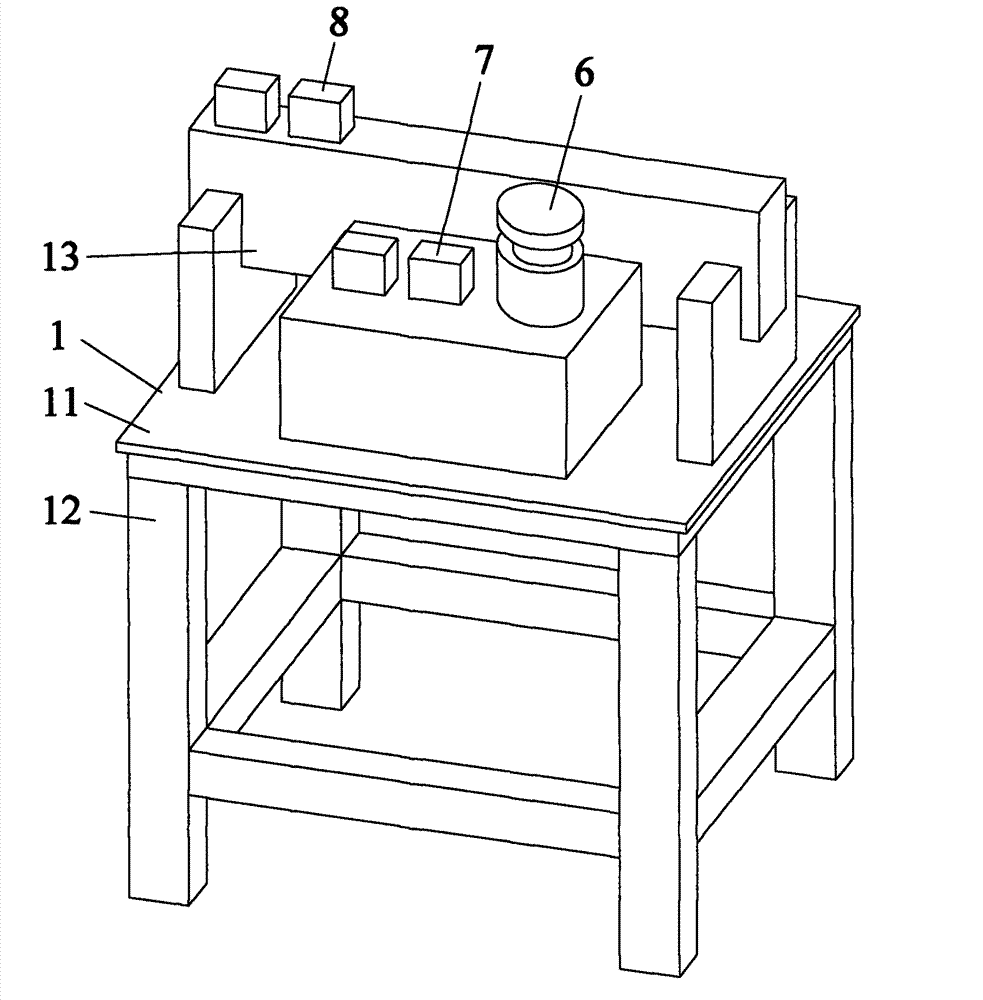

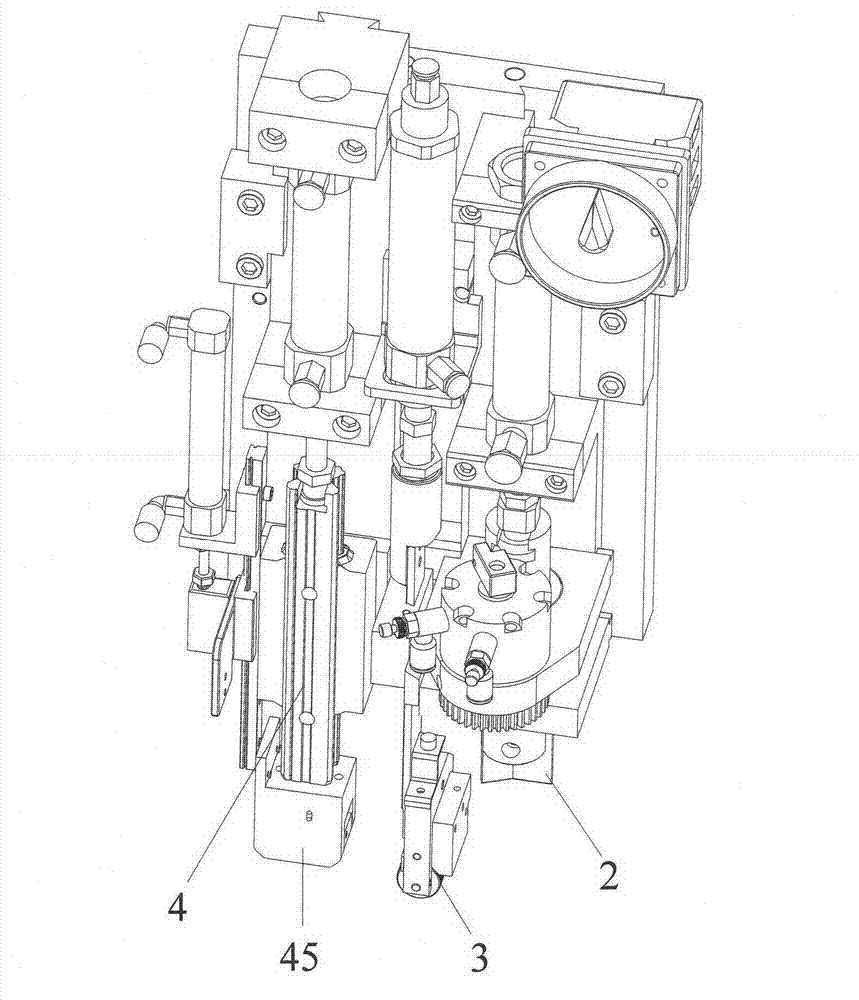

[0027] Please refer to Figure 1-5 , the folding and pressing system includes a gantry 1, a punching device 2, a gluing device 3, a hammer edge device 4, a flying knife loose-leaf folding device, a paper-cutting and pulling device 5, a glue tank 6, a heating element 7, Temperature control table 8, transmission device and computer control device.

[0028] The gantry 1 includes a table top 11 and four supporting feet 12 , a system installation seat 13 is provided in the middle of the upper surface of the table top 11 , and a control switch 14 is provided on the front side wall of the system installation seat 13 .

[0029] The punching device 2 is located on the front side of the system mounting base 13, the punching device 2 is mounted on the system mounting base 13 movable up and down, and the upper part of the punching d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com