Adjustable leatherworking edge pressing device

A hemming device and adjustable technology, applied in raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather/fur mechanical treatment, etc., can solve the problem of leather or fur Few cloth processing directions, poor practicability, and large limitations, etc., to achieve the effect of simple structure, strong practicability, and good cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

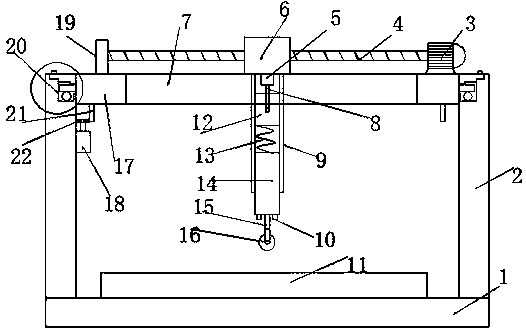

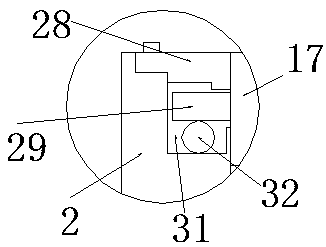

Embodiment 1

[0020] see Figure 1~2 , in the embodiment of the present invention, an adjustable leather processing edge pressing device includes a base 1, a working plate 11 is placed in the middle of the upper end of the base 1, and a support plate 2 is symmetrically provided on both sides of the upper end of the base 1, and the support plate 2 The upper end is provided with a supporting frame, and the middle of the supporting frame is connected with a rotating seat 17 through a rotating mechanism 20. The rotating seat 17 is provided with a horizontal chute hole 7, and the upper end of the rotating seat 17 where the horizontal chute hole 7 is located slides and is provided with a horizontal slider 6. The horizontal slider 6 is connected and fixed with the rotating seat 17 through a horizontal transmission mechanism. The lower end of the horizontal slider 6 is connected to the pressure rod 15 through a lifting mechanism. The lower end of the pressure rod 15 is provided with a pressure rolle...

Embodiment 2

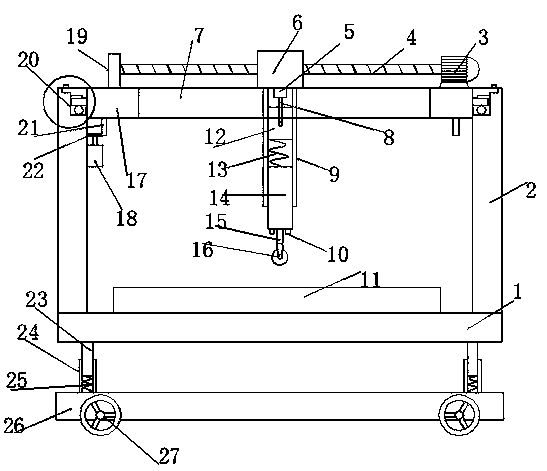

[0026] see image 3 The difference from Embodiment 1 is that a buffer mechanism is provided below the base 1, the buffer mechanism includes a buffer seat 26, and the left and right sides of the buffer seat 26 are provided with rollers 27 for easy device handling, and the rollers 27 are self-locking rollers , the two sides of the upper end of the buffer seat 26 are symmetrically provided with buffer sleeves 24, the upper end of the buffer sleeve 24 slides and is provided with a buffer rod 23, the upper end of the buffer rod 23 is connected and fixed with the lower end of the base 1, and the buffer sleeve 24 is internally provided with a buffer spring 25, the buffer spring 25 connects and fixes the buffer rod 23 and the buffer sleeve 24, and the setting of this buffer mechanism greatly improves the shock resistance of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com