Method for trimming cow leather

A technology for trimming and leather, applied in the field of cow leather production technology, can solve the problems of the influence of the integrity of the leather and the yield of the finished leather, the number of times of trimming the blank leather, and the high requirements of the operator, so as to avoid repeated trimming operations. , The effect of reducing leather width and technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

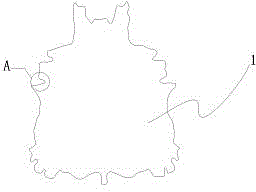

[0023] As the wet-blue leather 1 of crust leather, the limbs, head and tail, belly and girdle, fringes, sharp corners, and holes waiting for trimming position A all need to be trimmed, such as figure 1 shown.

[0024] A method for trimming cow leather, comprising the following process steps:

[0025] 1. Prepare the wet blue leather, and carry out conventional squeezing, stretching, and shaving treatments on the wet blue leather, and the shaved thickness is controlled at 1.00-1.05mm;

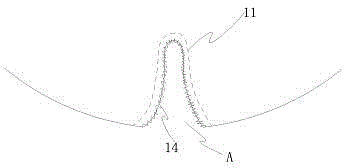

[0026] 2, sewing: by sewing machine, the collagen fiber thread with intensity greater than 6 gram deniers is used as suture 14 to carry out the sewing operation that the pin code density is 5 needles / cm at position A to be trimmed in wet blue leather, and described sewing operation is Overlock sewing along the edge track of the position A of the wet-blue leather to be trimmed, such as image 3 As shown, the suture 14 locks the edge of the position A of the wet blue leather to be trimmed, which ...

Embodiment 2

[0050] A cowhide trimming method, the overall process steps are completely consistent with the embodiment 1, the difference is that the stitch density of the sewing operation is 6 stitches / cm.

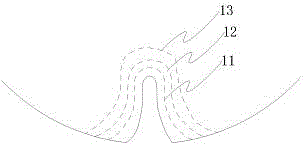

[0051] Compared figure 2 , image 3 , Figure 4 The schematic diagram of trimming structure in figure 2 After adopting the existing technology to trim the position A of the wet blue leather to be trimmed, after repeatedly passing through the trimming line 11 for the first time, the trimming line 12 for the second time, and the trimming line 13 for the third time, the wet blue leather to be trimmed The trimming opening at position A is getting bigger and bigger, the trimming range is large, the integrity of the wet blue leather is low, and the overall stretch will be reduced in a large area, resulting in a lot of waste of leather materials; and image 3 , Figure 4 After the cowhide trimming method described in Embodiment 1 and Embodiment 2 of the present invention is used to trim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com