Seam pressing device for bag processing

A technology of edge pressing device and luggage, applied in application, trimming of leather edges, mechanical processing of small raw hides/large raw hides/leather/fur, etc., can solve problems such as increasing defective rate, affecting processing efficiency, etc. performance, improve processing efficiency, and the adjustment process is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

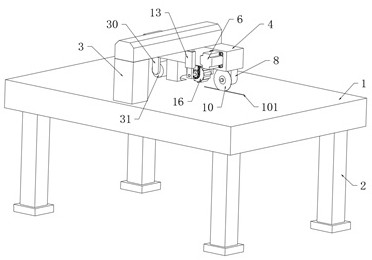

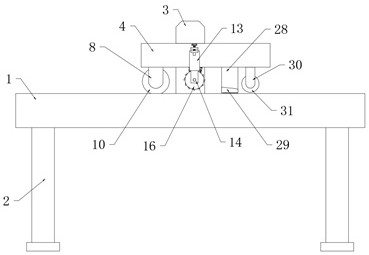

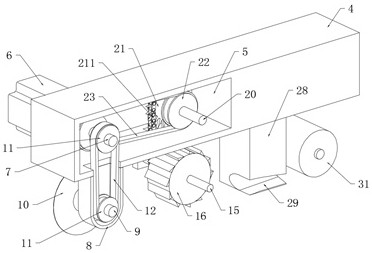

[0027] Refer Figure 1-7 Slotted blank processing means for luggage, comprising a console, the console 1 is fixedly connected to the bottom of the root support feet plurality 2, the welding end console 1 is an L-shaped bracket 3, the bracket 3 away from the operation 1 is fixedly connected to an end station mounting box 4, defines a cavity 5, the bottom tank wall mounting box 4 is fixedly connected to the transmission box 8, the inner space of the transmission case 8 communicates with the cavity 5, the transmission box 8 located in the installation box 4 on the inner wall sides of the bottom of a first rotary shaft rotatably connected through a bearing 9, the first end of the rotary shaft 9 extends to the outer case 8 and the gear coaxially fixedly connected with a slotted knife 10, the console 1 is positioned directly below opening seam ripper 10 a first position defines a cutting groove 101, the installation box 4 and the transdermal device equipped with shovel means blank, the c...

Embodiment 2

[0033] Refer Figure 8-9 , Located on both sides of the console 1 on the position of the mounting box 4 defines two parallel and equal-length guide grooves 32, each rolling guide groove 34 connecting the two pulleys 32, four upper pulley 34 fixedly connected with a common moving plate 33, slit blade 10 is located defines a location of a second cutting grooves 35, 35 located on respective sides of the second cutting grooves on the moving plate 33 defines a pair of moving slots 36, two pairs of grooves 36 are positioned on the moving plate 33 moves both ends of the moving plate 33, the movement of each slide groove 36 is connected to the mobile rod 37, the upper end of each movement of the rod 37 are fixedly connected to a top plate 38, the slide 37 together two moving rods 36 within each pair of moving slots is connected to a crosspiece 39, each movement of the rod 37 and the sleeve 38 is provided with a bottom surface of the top plate 39 and an upper crosspiece 40 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com