Smooth edge cutting equipment for leather

A technology of trimming and leather, which is applied in the field of smooth trimming equipment, can solve the problems of lower production efficiency and different degrees of thinning, so as to reduce the probability of problems, reduce the problem of uneven edges, and improve the beauty management. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

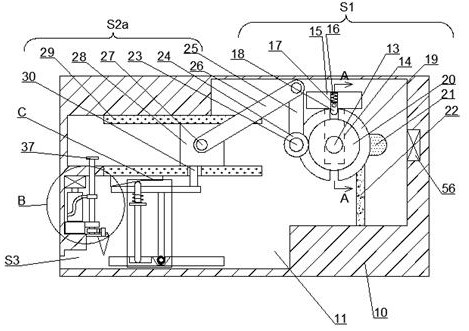

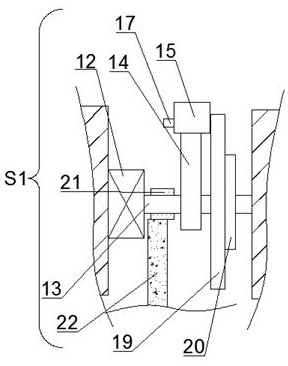

[0023] Such as Figure 1-7 Shown, a kind of smooth trimming equipment for leather, comprises frame (10), and described frame (10) interior is provided with main chamber (11), and described main chamber (11) is provided with by motor An intermittent motion device (S1) capable of making the main shaft gear (20) stop for half a circle after every half circle as the main force. The intermittent movement device (S1) can realize the intermittent action through the ingenious mechanical structure, thereby greatly reducing the control cost of the equipment and improving the reliability of the equipment operation.

[0024] The main chamber (11) is also provided with an oblique motion module (S2a) driven by the intermittent motion device (S1) to make the connecting pin (30) obliquely move, and the main chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com