Unhairing machine

A technology for a hair removal machine and a frame, which is applied in the field of hair removal machines, can solve the problems of easy corrosion of raw hides, pollution of the environment, easy production of industrial waste water, etc., and achieves the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

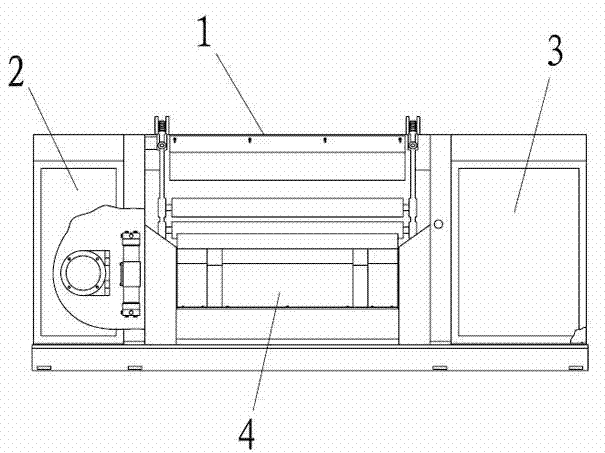

[0035] Embodiment 1: as figure 1 As shown, a hair removal machine includes a frame 1, a hydraulic system 2 located on one side of the frame 1, an electrical cabinet 3 located on the other side of the frame 1, and a transmission mechanism 4 located in the middle of the frame 1.

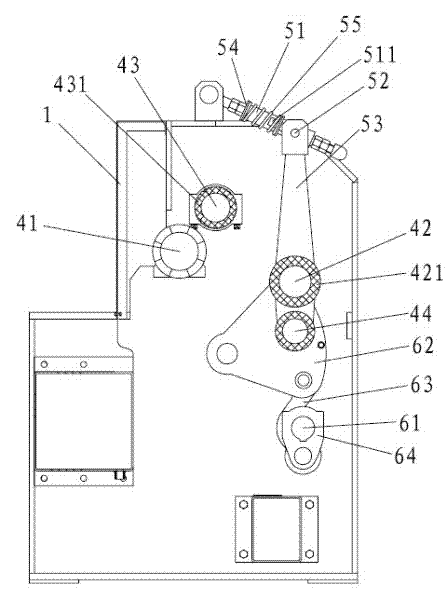

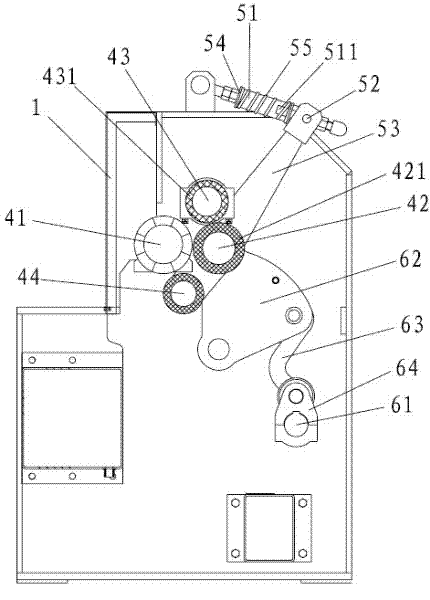

[0036] Such as Figures 2 to 3As shown, the transmission mechanism 4 includes an elastic compensation structure and a feed structure. The elastic compensation structure includes a slide bar 51 with one end hinged on the top of the frame 1 and having a chute 511, on the slide bar 51 and close to the slide bar 51 and the machine. A limit plate 54 is fixed at the hinge of the frame 1, a sliding column 52 is slidably connected in the chute 511, and a spring 55 that is always in a compressed state and is sleeved outside the slide bar 51 is arranged between the sliding column 52 and the limiting plate 54. The column 52 is hinged with one end of the connecting plate 53; the feed structure includes a synchron...

Embodiment 2

[0044] Embodiment 2: The difference from Embodiment 1 is that there are 6 left-handed threaded knife bands 412 and right-handed threaded knife bands 413 .

Embodiment 3

[0045] Embodiment 3: The difference from Embodiment 1 or 2 is that there are seven left-handed threaded knife bands 412 and right-handed threaded knife bands 413 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com