Ultralow-temperature cooling medium internal spraying type mechanical main shaft

A cooling medium and ultra-low temperature technology, which is applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of spindle frosting, heat insulation, sealing difficulty, cold air medium temperature is not as low as liquid nitrogen temperature, etc. , to prevent leakage and heat transfer, ensure dimensional accuracy, and meet the effects of zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

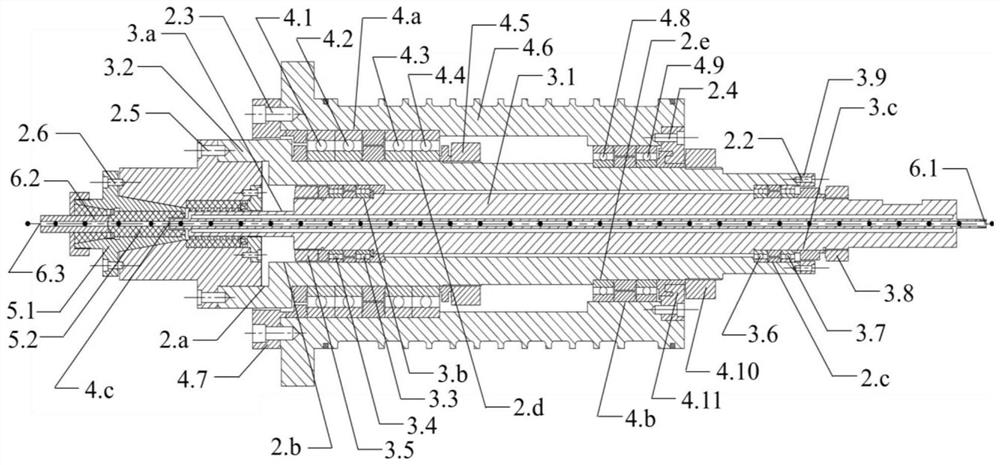

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and technical solutions.

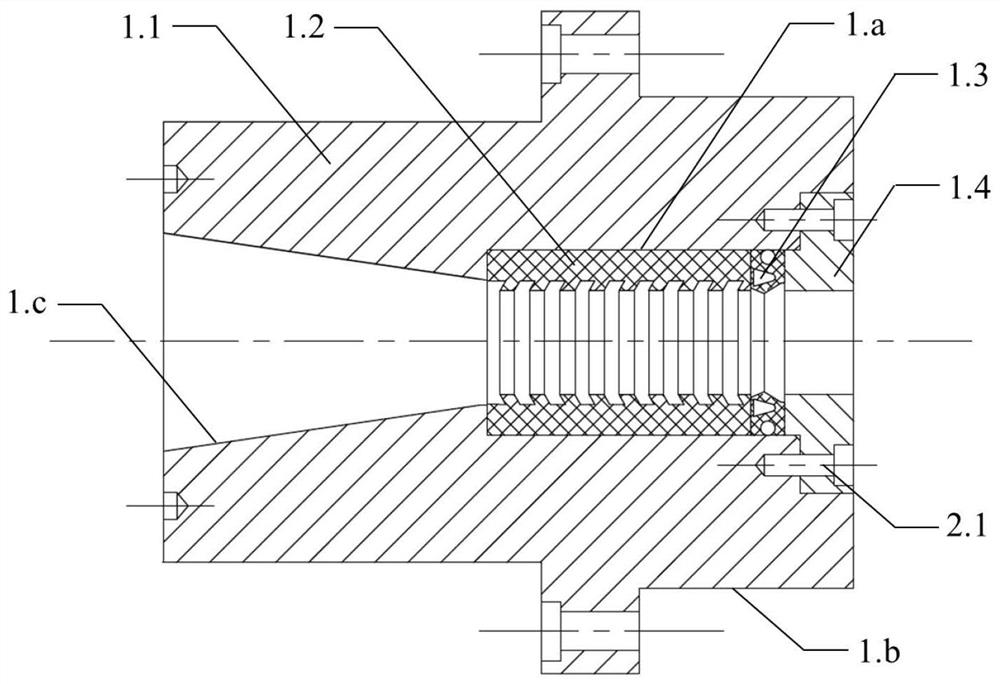

[0018] In this embodiment, the ultra-low temperature cooling medium is liquid nitrogen, the main shaft specification is BT40, the outer diameter of the main shaft housing 4.6 is 180 mm, and all bearings are angular contact ball bearings; the outer circular surface 3.a of the front end of the vacuum mandrel 3.1 is The outer diameter is 20mm, and the thermal conductivity of the vacuum mandrel 3.1 is approximately 0; the materials of the heat-insulating labyrinth seal 1.2 and the heat-insulating layer 5.2 of the handle are all modified polyimide, and the thermal conductivity is less than 0.15W / (m·K) ;Adiabatic labyrinth seal 1.2 has 9 sealing teeth in total, inner diameter 20.4mm, outer diameter 40mm, length 53mm, tooth height 3.5mm; lip seal 1.3 is made of modified polyetheretherketone, and the working temperature range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com