Mechanical leather splitting machine

A mechanical, leather technology, applied in leather manufacturing, small raw hide/large raw hide/leather/fur processing, small raw hide/large raw hide/leather/fur mechanical processing, etc., can solve the problems of complex structure and high power consumption, and achieve The effect of reducing electricity consumption, saving energy consumption and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

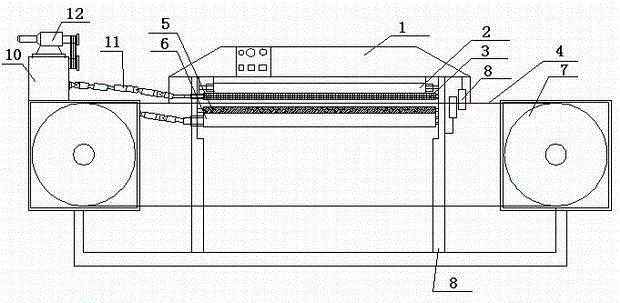

[0017] The upper part of the mechanical leather splitting machine is mainly the upper bridge frame 1 on the operation panel, and the working mechanism of the splitting machine in the middle. The rubber roller 6 has a cutter wheel 7 on the left and right sides, the pressure roller 2 is pressed tightly on the flower roller 3, the ring belt knife 4 is located between the flower roller 3 and the ring roller 5, and keeps a certain distance, and the ring belt knife 4 sets Connected to the rims of the two cutter wheels 7, the rubber roller 6 is pressed under the ring roller 5, and the lower part is the lower support body 8.

[0018] The flower roller 3 and the rubber roller 6 are respectively connected to corresponding universal joints 11, and the universal joints 11 are connected to a transmission 10, and the transmission 10 is connected to a variable frequency motor 12 through a belt.

[0019] Two emery wheels 9 are positioned at the right side of upper bridge frame 1, are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com