Spiral runner hydraulic test platform

A technology of hydraulic experiment and rotating wheel, which is applied in the direction of hydropower generation, engine components, machines/engines, etc., can solve the problems of immature hydraulic design, and achieve the effect of saving materials, reducing weight and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

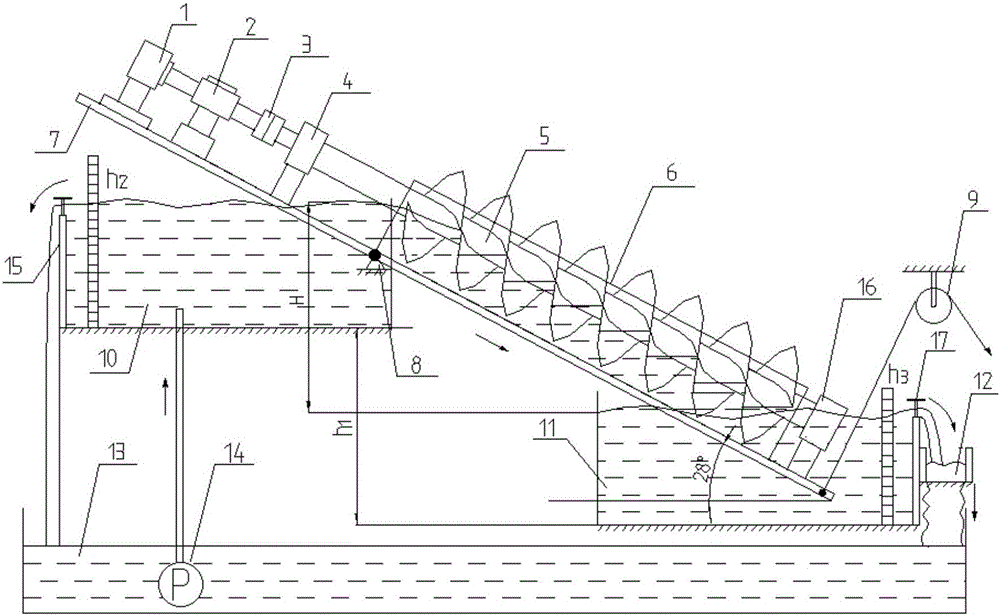

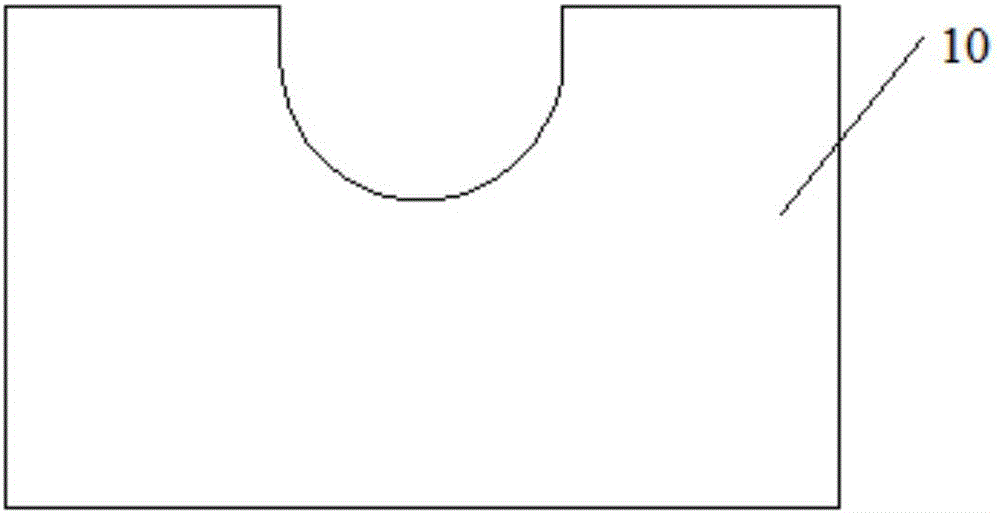

[0039] Embodiment: a kind of helical runner hydraulic generator test bench, such as figure 1 As shown, it includes a magnetic powder brake 1, a torque meter 2, a coupling 3, a bearing device A, a spiral runner 5, a semicircular groove 6, a bracket body 7, a hinge 8, a pulley 9, an upper water tank 10, a lower water tank 11, An open channel 12, a pool 13 and a water pump 14; the magnetic powder brake 1, the torque meter 2, and the spiral runner 5 are sequentially connected coaxially; A and the bearing device B are fixed in the semicircular groove 6, and keep a certain gap; the support body 7 supports the magnetic powder brake 1, the torque meter 2, the bearing device A, the bearing device B, and the semicircular groove 6; the hinge 8 is connected to the position of the support body 7 close to the entrance of the spiral runner, and the pulley 9 is connected to the lower end of the support body 7, and cooperates with each other to make the spiral runner 5 and the horizontal becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com