Chromium-free tanning agent and preparation method thereof

A chrome-free tanning agent and solvent technology, applied in the field of chrome-free tanning agent and its preparation, can solve the problems of ecological environment damage, complicated tanning process, limited chrome resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

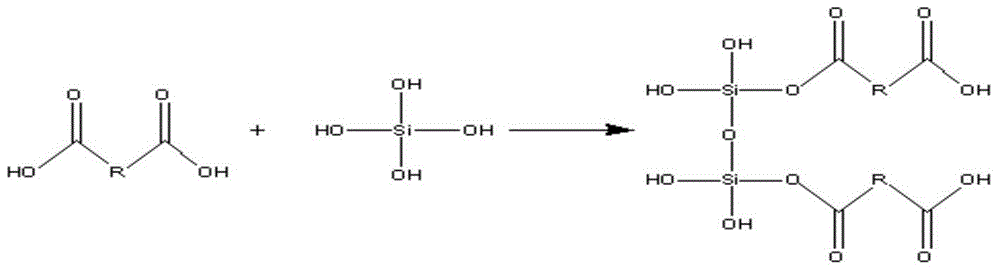

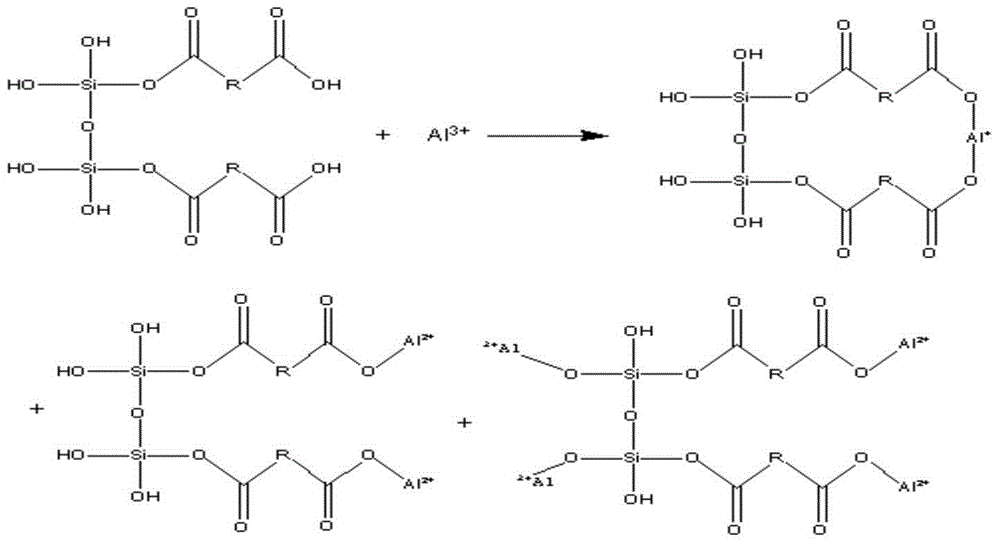

Method used

Image

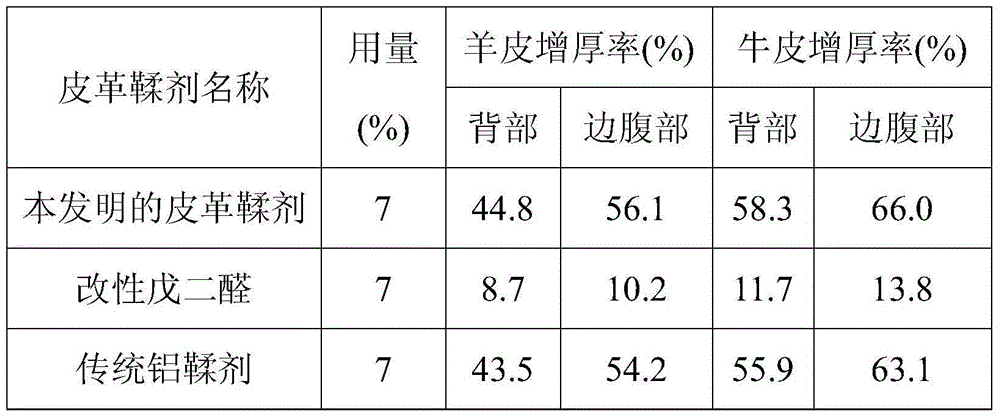

Examples

Embodiment 1

[0028] A preparation method of chrome-free tanning agent, comprising the following steps:

[0029] Add 10 parts of sodium silicate to 100 parts of soft water, then add dropwise to the solution prepared by 10 parts of sulfuric acid, 10 parts of acetic acid, 5 parts of citric acid, 5 parts of lactic acid and 100 parts of water, and then add to the above The solution prepared by adding 50 parts of aluminum trichloride and 100 parts of water is added dropwise to the solution after the dropwise addition. After the dropwise addition is completed, the tanning agent solution is obtained. The tanning agent solution is spray-dried with an air volume of 80% and an air inlet temperature of 120°C. The feed rate is 10mL / min, and the chrome-free tanning agent product is obtained, which is stored dry, and the stated parts are parts by mass.

Embodiment 2

[0031] A preparation method of chrome-free tanning agent, comprising the following steps:

[0032] Add 10 parts of ethyl silicate to 100 parts of ethanol, and then dropwise into In the solution, then in the solution that above-mentioned dripping is finished, add the solution that 50 parts of aluminum trichlorides and 100 parts of waters are prepared drop by drop, promptly get tanning agent solution after dropping, the tanning agent solution is spray-dried air volume 80%, The air inlet temperature is 180°C, and the feed rate is 10mL / min, to obtain a chrome-free tanning agent product, which is stored in a dry place, and the stated parts are parts by mass.

Embodiment 3

[0034] A preparation method of chrome-free tanning agent, comprising the following steps:

[0035] Add 100 parts of sodium silicate to 50 parts of soft water, and then dropwise add it to the In the prepared solution, then add dropwise the solution prepared by 10 parts of aluminum trichloride and 20 parts of water to the solution that has been added dropwise. After the dropwise addition is completed, the tanning agent solution is obtained, and the tanning agent solution is spray-dried with an air volume of 100 %, the air inlet temperature is 120°C, and the feed rate is 10mL / min, and the chrome-free tanning agent product is obtained, which is stored dry, and the stated parts are parts by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com