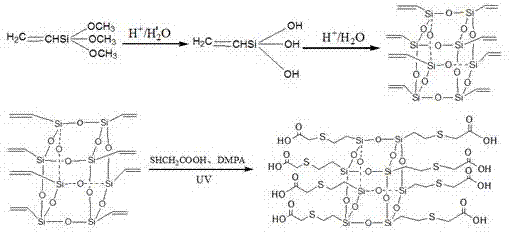

Water-soluble octacarboxyl silsesquioxane tanning agent prepared by mercaptan-alkene click chemistry process and method thereof

A technology of silicone tanning agent and silsesquioxane, which is applied in the field of water-soluble octacarboxysilsesquioxane tanning agent to achieve the effects of high speed, good water solubility and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 33mL of vinyltrimethoxysilane into a 1000mL three-necked flask at 35°C, then add 337mL of acetone, and place in a water bath equipped with a condenser and a heating stirrer. Slowly add the diluted hydrochloric acid into the flask, reflux and stir at 35°C for 40h, wash the product with 66mL of absolute ethanol for 3 times after the reaction, and then vacuum-dry it at 45°C for 48h to obtain white powdery cage-type Vinyl silsesquioxane; then dissolve the cage-type octavinyl silsesquioxane with an appropriate amount of dichloromethane, and wait for the solvent to evaporate for a certain period of time to form a homogeneous saturated solution and crystallize a white solid.

[0045] Weigh 0.2132g of cage-type octavinylsilsesquioxane and 0.2764g of mercaptoacetic acid and dissolve them in dichloromethane to form a colorless, transparent and clear solution. Then add 0.0048g of 1wt% photoinitiator benzoin dimethyl ether, place it in a conical flask, irradiate for 5min under ...

Embodiment 2

[0047]Add 45mL of vinyltrimethoxysilane into a 1000mL three-necked flask at 45°C, then add 337mL of acetone, and place in a water bath equipped with a condenser and a heating stirrer. Slowly add diluted hydrochloric acid into the flask, reflux and stir at 45°C for 40h, after the reaction, wash the product with 66mL of absolute ethanol for 3 times, and then vacuum-dry it at 45°C for 48h to obtain a white powdery cage Vinyl silsesquioxane; then dissolve the cage-type octavinyl silsesquioxane with an appropriate amount of dichloromethane, and wait for the solvent to evaporate for a certain period of time to form a homogeneous saturated solution and crystallize a white solid.

[0048] Weigh 0.2132g of vinyl silsesquioxane and 0.2764g of mercaptoacetic acid and dissolve them in dichloromethane to form a colorless transparent clear solution. Then add 0.0048g of 1wt% photoinitiator benzoin dimethyl ether, place it in a conical flask, irradiate for 5min under an ultraviolet lamp, and ...

Embodiment 3

[0050] Add 33mL of vinyltrimethoxysilane into a 1000mL three-neck flask at 40°C, then add 337mL of acetone, and place in a water bath equipped with a condenser and a heating stirrer. Slowly add diluted hydrochloric acid into the flask, reflux and stir at 35°C for 40h, after the reaction, wash the product with 66mL of absolute ethanol three times, and then vacuum-dry at 45°C for 48h to obtain a white powdered cage Vinyl silsesquioxane; then dissolve the cage-type octavinyl silsesquioxane with an appropriate amount of dichloromethane, and wait for the solvent to evaporate for a certain period of time to form a homogeneous saturated solution and crystallize a white solid.

[0051] Weigh 0.2132g of cage-type octavinylsilsesquioxane and 0.2764g of mercaptoacetic acid and dissolve them in dichloromethane to form a colorless, transparent and clear solution. Then add 0.0048g of 1wt% photoinitiator benzoin dimethyl ether, place it in a conical flask, irradiate for 5min under an ultravi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com