Environment-friendly high fire-retardant melting sealed double-wall pipe

A double-wall pipe, high flame retardant technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of low quality, poor flame retardant effect and high cost of double-wall pipes, and achieve significant economical benefits. Benefits and environmental protection benefits, low longitudinal shrinkage, good shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

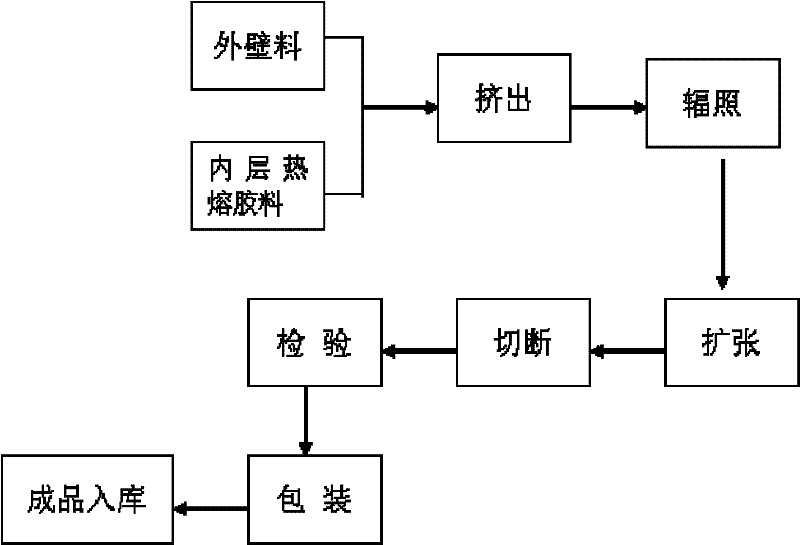

[0019] The preparation process of the double-wall pipe is as follows:

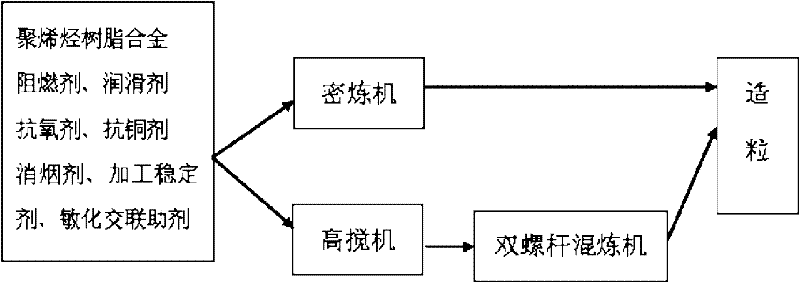

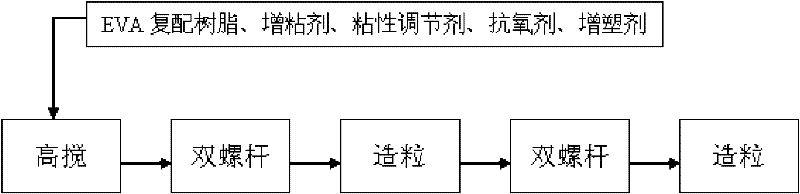

[0020] (1) Preparation of the outer wall material of the flame retardant double-wall pipe: the proportion of each component of the raw materials, according to the mass fraction: poly-polyolefin mixed resin 40-45 parts, flame retardant 50-58 parts, lubricant 1-2 parts, antioxidant 1-2 parts of anti-copper agent, 0.5 parts of anti-copper agent, 2-3 parts of smoke suppressant, 2 parts of processing stabilizer, 2 parts of sensitizing cross-linking auxiliary; the polyolefin mixed resin is EVA630, EVA421, EVA28-3 The polyolefin mixed resin obtained by melt blending with EVA220 four kinds of polyolefin materials; the components of the raw materials are added to the internal mixer according to the proportion or added to the twin-screw mixer after being stirred by a high-speed mixer, at 160± Under the temperature condition of 10 ℃, after full stirring and mixing, the screw speed is 100-125 rpm, and the mixing tempe...

Embodiment 1

[0042] The preparation process of the double-wall pipe is as follows:

[0043] (1) Prepare the outer wall material of the flame-retardant double-walled pipe: the proportion of each component of the raw materials, according to the parts by mass: 40 parts of polyolefin mixed resin, 50 parts of flame retardant, 1 part of paraffin, and 1010 (four (β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid) pentaerythritol ester) 1 part, anti-copper agent: hydroxy-terminated polybutadiene acrylonitrile liquid rubber MDA-10240.5 parts, smoke suppressant: zinc borate 2 parts, processing stabilizer: rare earth composite stabilizer (REC series, such as REC-LS-A or REC-LS-B commonly sold in the market) 2 parts, sensitizing cross-linking aid: 2 parts trimethylolpropane TMP Described polyolefin mixed resin is the polyolefin mixed resin obtained by melt blending four kinds of polyolefin materials of EVA630, EVA421, EVA28-3 and EVA220; The polyolefin mixed resin in step (1) is to be by weight pe...

Embodiment 2

[0056] The preparation process of the double-wall pipe is as follows:

[0057] (1) Prepare the outer wall material of the flame-retardant double-wall pipe: the proportion of each component of the raw materials, according to the parts by mass: 45 parts of polyolefin mixed resin, 58 parts of flame retardant, 2 parts of paraffin, and 1010 parts of antioxidant (tetra(β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid) pentaerythritol ester) 2 parts, anti-copper agent: 0.5 part of hydroxyl terminated polybutadiene acrylonitrile liquid rubber MDA-1024, smoke suppressant: zinc borate 3 parts, processing stabilizer: 2 parts rare earth composite stabilizer (REC-LS-D or REC-LS-F), sensitizing crosslinking aid: 2 parts trimethylolpropane TMP; the polyolefin mixed resin is The polyolefin mixed resin obtained by melt-blending four kinds of polyolefin materials of EVA630, EVA421, EVA28-3 and EVA220; the polyolefin mixed resin in step (1) is to be by weight percentage: EVA63025%, EVA421 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com