A functional masterbatch for strengthening and toughening polylactic acid fiber, preparation method thereof, and strengthening and toughening polylactic acid material

A polylactic acid fiber, reinforcement and toughening technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, final product manufacturing, etc., can solve the problems that cannot be reinforced and toughened with polylactic acid fiber, poor fiber spinnability, etc., to prevent agglomeration , help depolymerization, improve the effect of processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

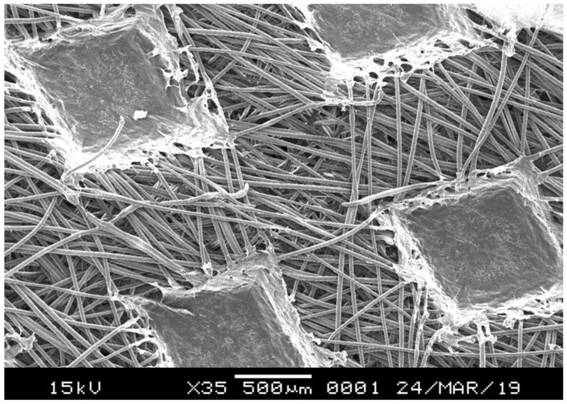

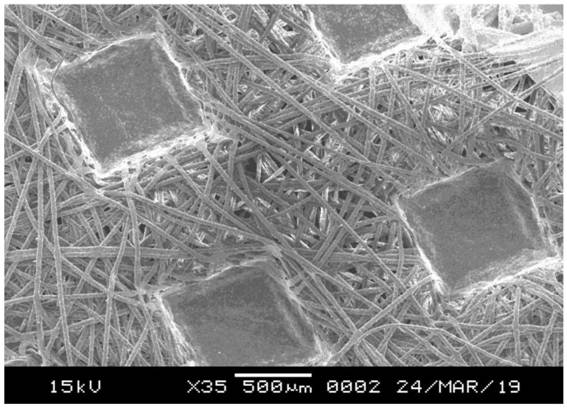

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of a functional masterbatch for strengthening and toughening polylactic acid fibers, comprising the following steps:

[0031] The inorganic mineral powder is mixed with a surface modifier, and surface modification is carried out to obtain a modified inorganic mineral powder; the surface modifier is at least one of a silane coupling agent, a titanate coupling agent and an aluminate coupling agent ;

[0032] Mixing the modified inorganic mineral powder with a dispersant, and performing pre-dispersion treatment to obtain pre-dispersed modified inorganic mineral powder;

[0033] The pre-dispersed modified inorganic mineral powder is mixed with polylactic acid resin, modifier, antioxidant and stabilizer and then plasticized, kneaded, extruded and granulated in turn to obtain polylactic acid for strengthening and toughening. The functional masterbatch of fiber; the modifier is ethylene-vinyl acetate copolymer, random polypropylene,...

Embodiment 1

[0062] Put 60 parts of 4500-mesh calcite powder in a high-speed mixer, heat up to 110°C, and at the same time, start stirring, first stir at 490rpm for about 1 minute, and then stir at 980rpm for 3 minutes, drain water, and then use The spraying method is in a high-speed stirring state, adding 1.5 parts of pyrophosphoric acid type monoalkoxy titanate (the trade name of Yizheng Tianyang Chemical Co., Ltd. is TM- 38s), continue to stir and heat at 110 ° C with a rotating speed of 980 rpm for 10 min to obtain a modified calcite powder with an activation degree of 100%;

[0063] The modified calcite powder is placed in a high-speed mixer, and 5 parts of low-molecular-weight ethylene-vinyl acetate copolymer wax (EVA wax) are added (molecular weight is 2300, product of Qingdao Zhongsu High-tech Materials Co., Ltd., and the trade name is EVAWax 400), Heating to 110°C, pre-dispersing at 980 rpm for 10 min, and then cooling to room temperature to obtain pre-dispersed modified calcite p...

Embodiment 2

[0066] Put 65 parts of 4000 mesh calcite powder in a high-speed mixer, heat it up to 110°C, stir at 490rpm for 1 minute, then stir at 980rpm for 3 minutes, drain the water, and then use the spray method to stir at a high speed. Next, add 2 parts of isopropyl tristearate titanate (the trade mark of Nanjing Aocheng Chemical Co., Ltd. is AC-100) after diluting with isopropanol as the diluent according to the mass ratio of 1: 1, continue at 110 ℃ with Stir and heat at 980rpm for 10min to obtain modified calcite powder with an activation degree of 100%;

[0067] The modified calcite powder was placed in a kneader, and 5 parts of low molecular weight polypropylene wax (product of Qingdao Zhongsu High-tech Materials Co., Ltd., trade mark H-525) was added, heated to 110 ° C, and carried out at a rotating speed of 980 rpm. Pre-dispersed for 10 min, then cooled to room temperature to obtain pre-dispersed modified calcite powder;

[0068] The pre-dispersed modified calcite powder and 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com