Automatic disassembling and assembling system for container spin lock

A container and automatic technology, applied in the field of automation systems, can solve problems such as low accuracy, high cost, and large equipment, and achieve the effects of improving unloading efficiency, large fault tolerance, and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

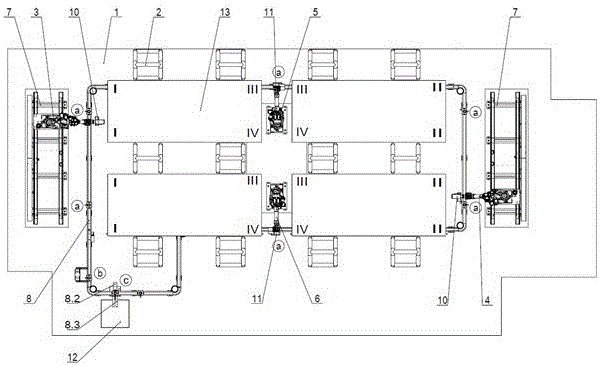

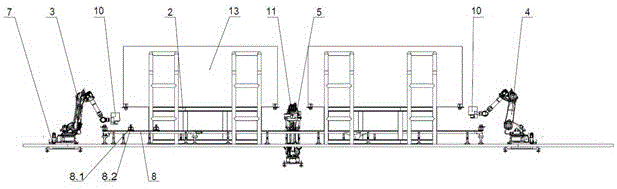

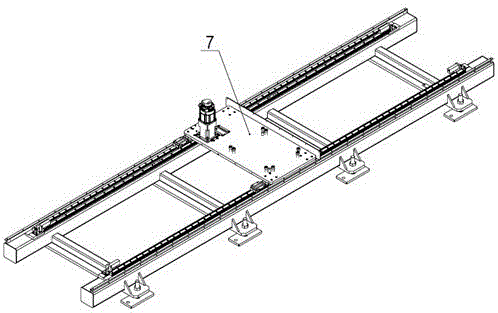

[0037]The automatic unloading system of the container fixed twist lock of the present invention is mounted on the transfer platform 1 of the quay bridge, and the system equipment is carried out as follows according to the space of the transfer platform 1 figure 1 layout shown. The system includes container parking platform 2; four industrial robots (including end robot Ⅰ 3 and end robot Ⅱ 4, middle robot Ⅲ 5 and middle robot Ⅳ 6); two robot walking mechanisms 7 (only one central robot is set , it is necessary to add a robot walking mechanism 7) in the middle; fix the twistlock transportation line body 8; clamp I 10, clamp II 11.

[0038] figure 1 , figure 2 It is illustrated with four complicated 20-foot container unloading twistlocks, wherein the 20-foot container 13 is parked on the container parking platform 2, and the container parking platform 2 adopts four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com