Machine for reassembling bearing seat of working roll with positioning function, and guarding against turning over measure

An anti-tipping, work roll technology, applied in mechanical equipment, manufacturing tools, metal processing and other directions, can solve the problems of low equipment positioning accuracy, potential safety hazards, and low automation, and achieve the elimination of potential safety hazards, high automation, and high automation. The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

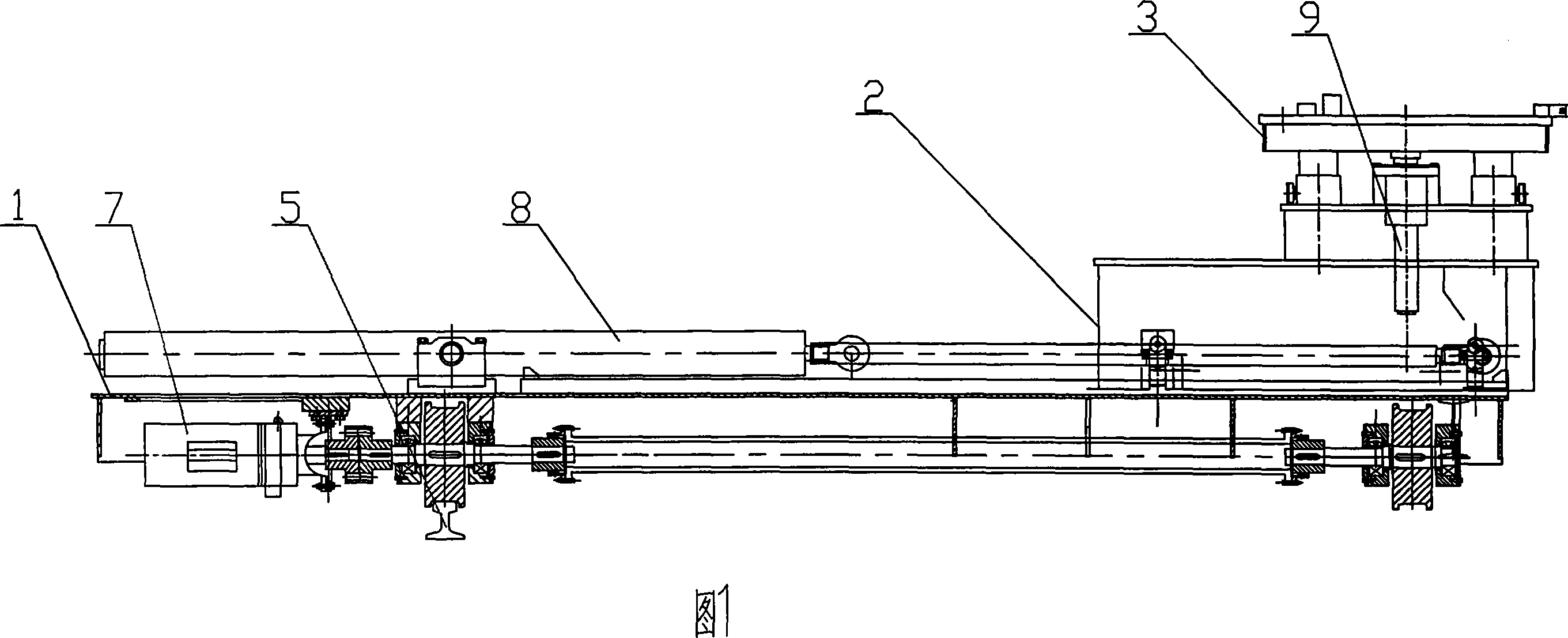

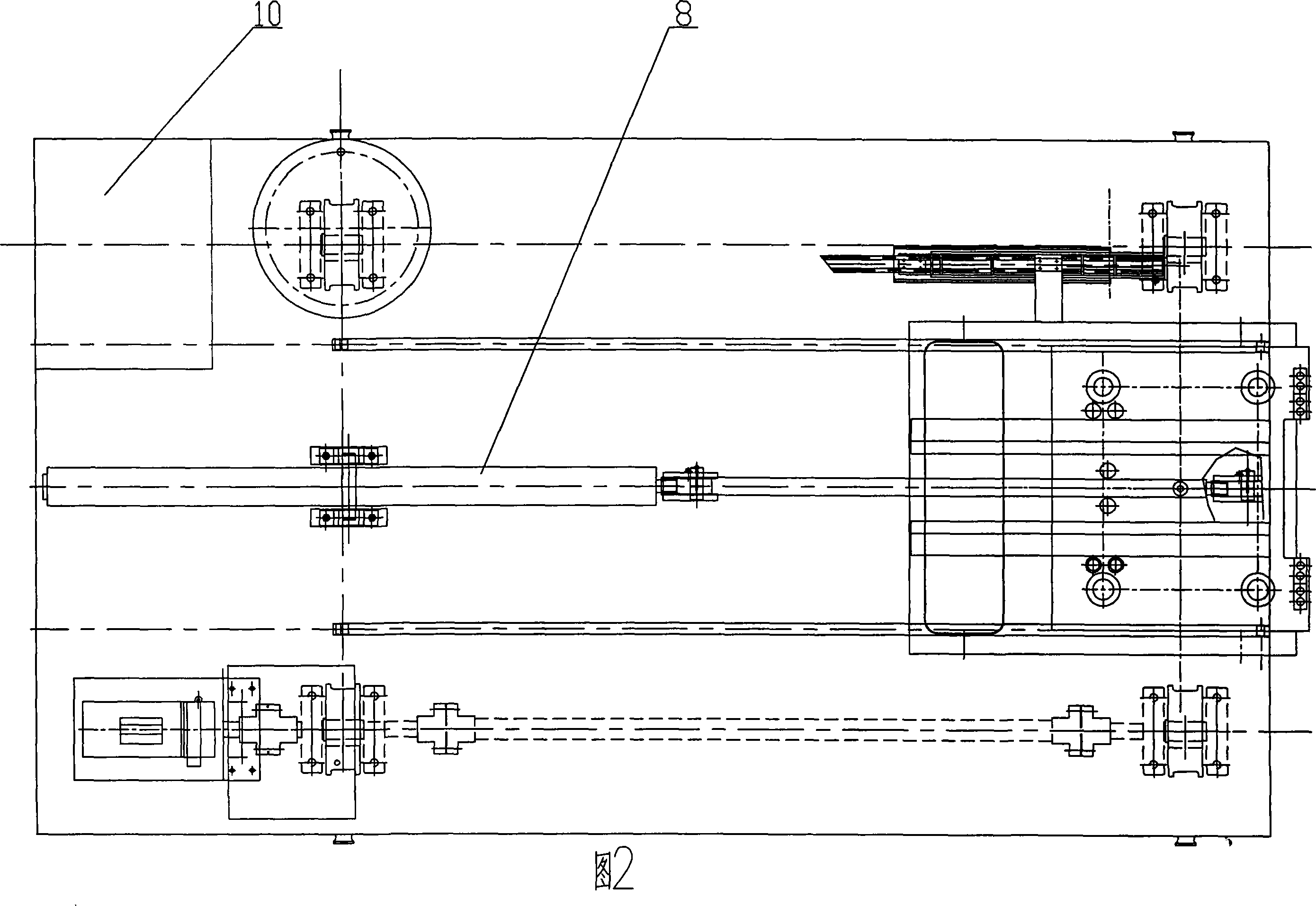

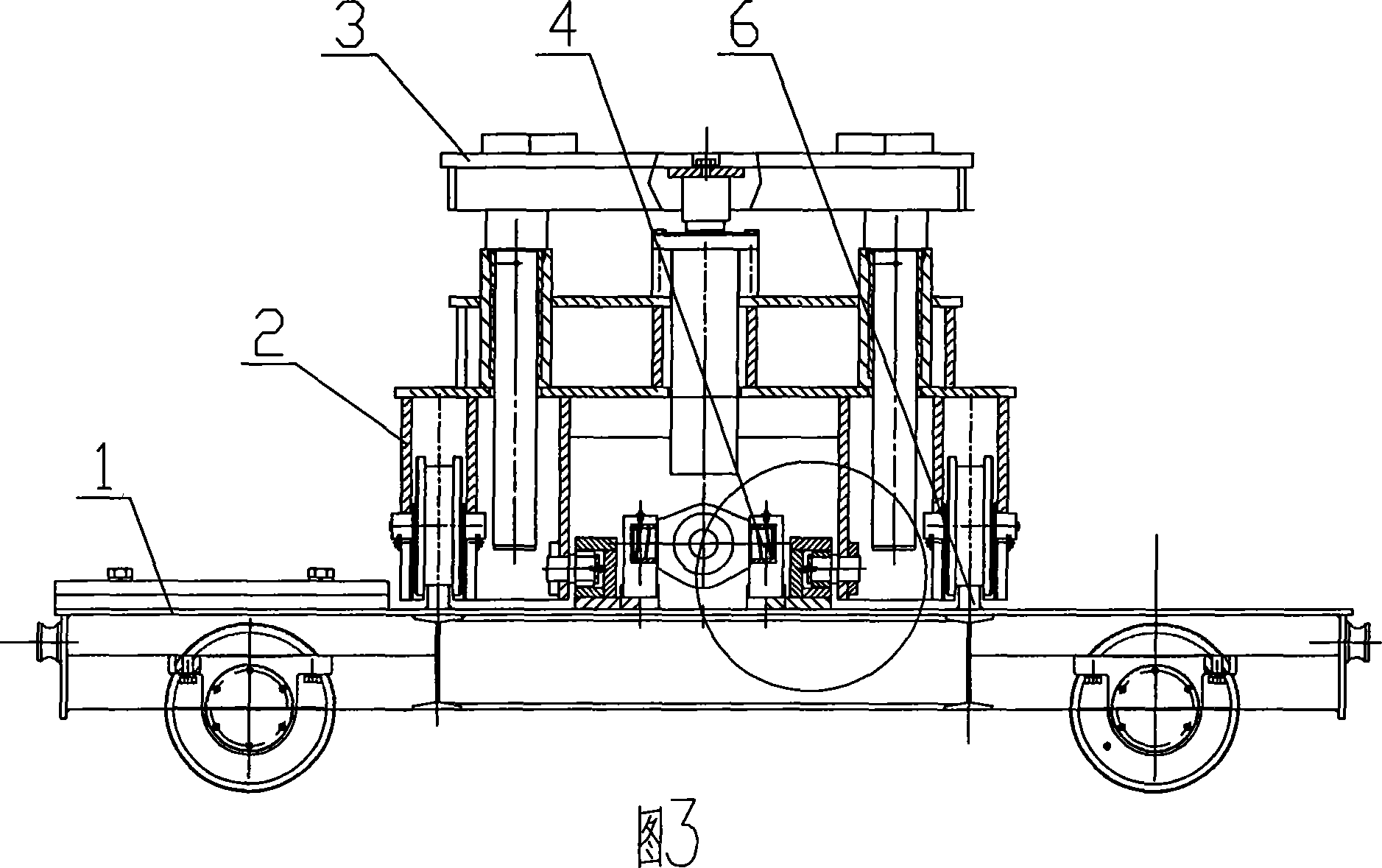

[0022] As shown in Fig. 1, Fig. 2, and Fig. 3, according to the work roll chock dismantling machine with positioning and anti-tipping measures of the present invention, it includes a base, a cart 1, a trolley 2, a lifting table 3, and an anti-tipping The device 4 is characterized in that a cart track 5 is arranged on the base, a cart 1 arranged on the cart track 5, a trolley track 6 arranged on the cart, a cart track 6 arranged on the cart The trolley 2 on the trolley, the upper lifting platform 3 on the trolley 2, the lower anti-overturning device 4, the deceleration motor 7 driving the cart, the horizontal hydraulic cylinder 8 driving the trolley, and the displacement sensor driving the lifting platform 3 Lifting hydraulic cylinder 9, an electrical console composed of an electrical control cabinet and a control panel connected with each of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com