Automatic cheese discharging machine

A kind of package yarn, automatic technology, applied in textile processing machine accessories, textile and papermaking, textile material processing and other directions, can solve the problem that the package yarn is loaded on the insertion rod in the middle, cannot guarantee the safety of the operator, and the unloading efficiency is low, etc. problem, to achieve the effect of convenient and fast cage loading, convenient cage loading, and high yarn unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

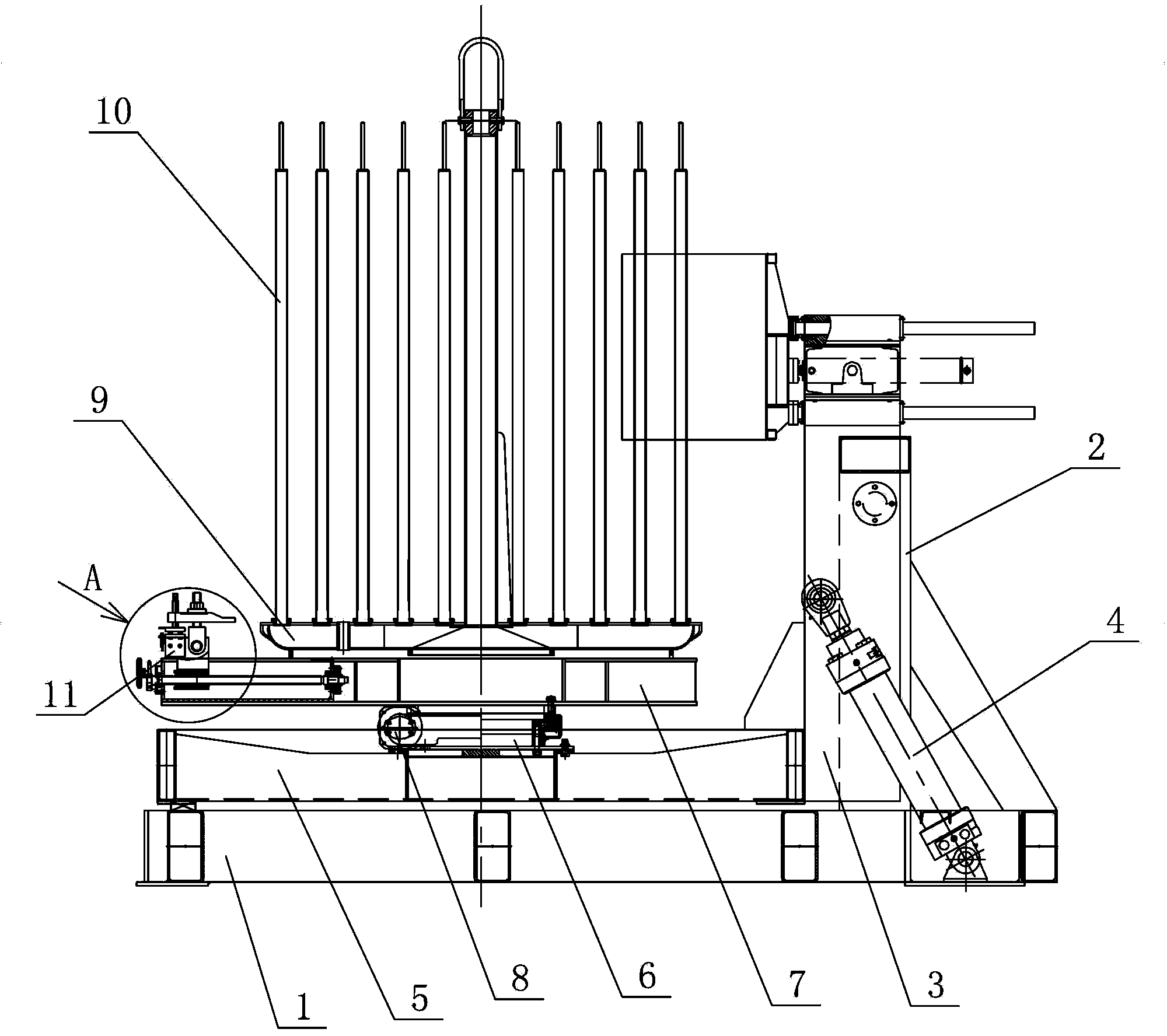

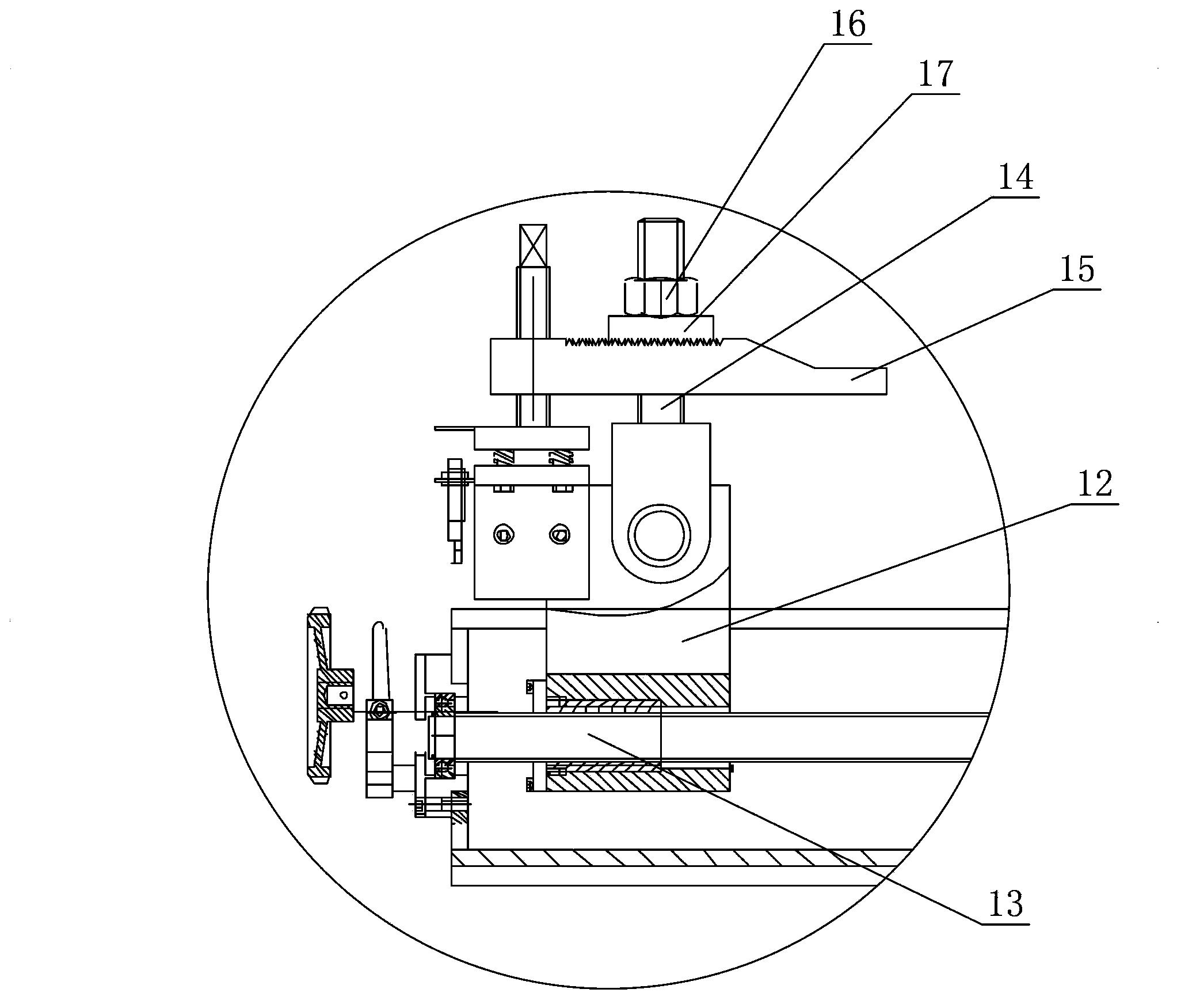

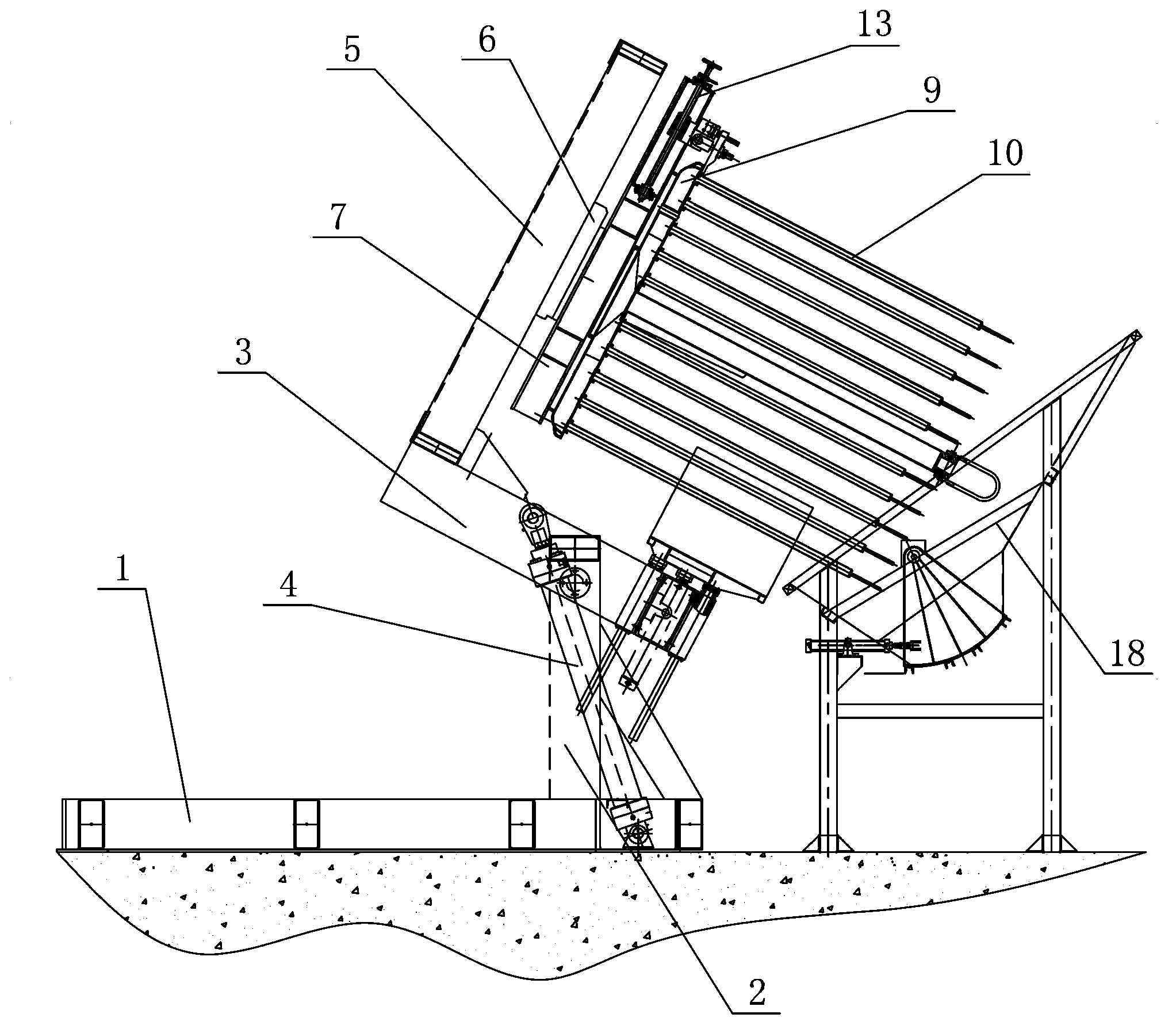

[0016] see Figure 1 to Figure 3 As shown, in this embodiment, an automatic cheese unloading machine includes a base 1, a fixed support 2 is vertically arranged on the base 1, and an overturning support 3 that can be turned over along the outside of the fixed support 2 is hinged. A drive cylinder 4 is installed on the overturn bracket 3, one end of the drive cylinder 4 is hinged on the base 1, the other end is hinged on the overturn bracket 3, and the bottom of the overturn bracket 3 is vertically connected to the overturn base 5 to one side, The turning base 5 is connected to the sarong fixing seat 7 through the rotary disc 6, and the rotary disc 6 is driven to rotate by the drive motor 8, and four sets of locking parts 11 for fixing the sarong are evenly distributed on the sarong fixing seat 7. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com