Container polyvinyl chloride powder logistics system

A polyvinyl chloride powder material and logistics system technology, which is applied to the types of packaging items, special packaging items, and conveying bulk materials, can solve problems such as low efficiency and complex links in the container logistics system, and achieve improved efficiency, improved shipping efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

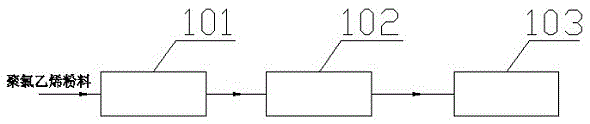

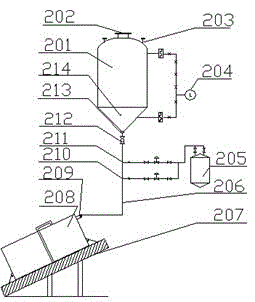

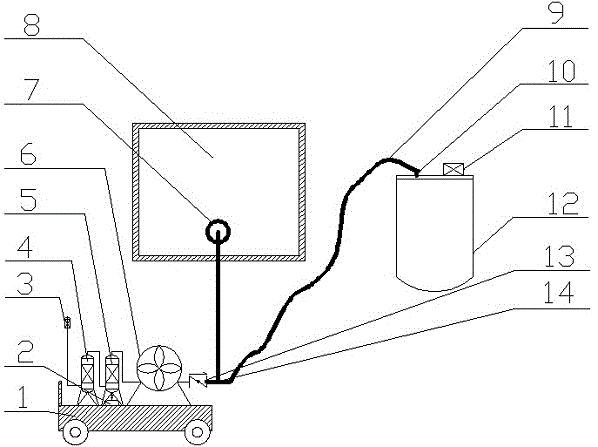

[0043] Refer to attached Figure 1-4 , a container polyvinyl chloride powder logistics system, including 3 links:

[0044] The first link is the filling link 101. The polyvinyl chloride powder from the packaging silo enters the filling device, and the polyvinyl chloride powder is filled in the container through the filling device, and the dust generated during the filling process is dedusted through the container device removal;

[0045] The second link is the transfer link 102. After the container is filled, it is transported to the place where the railway container is shipped by a pallet truck, and then loaded on a railway container assembly platform for shipment by train, and then transported to the user's site by a pallet truck;

[0046] The third link is the unloading link 103 at the user's site. When the container arrives at the user's site, the powder in the container is directly transported into the user's silo through the unloading device. After the unloading is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com