In-mold material taking oblique arm type mechanical arm

A manipulator and oblique arm technology, which is applied in the field of in-mold oblique arm manipulators, can solve the problems of low overall efficiency, high mold structure requirements, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

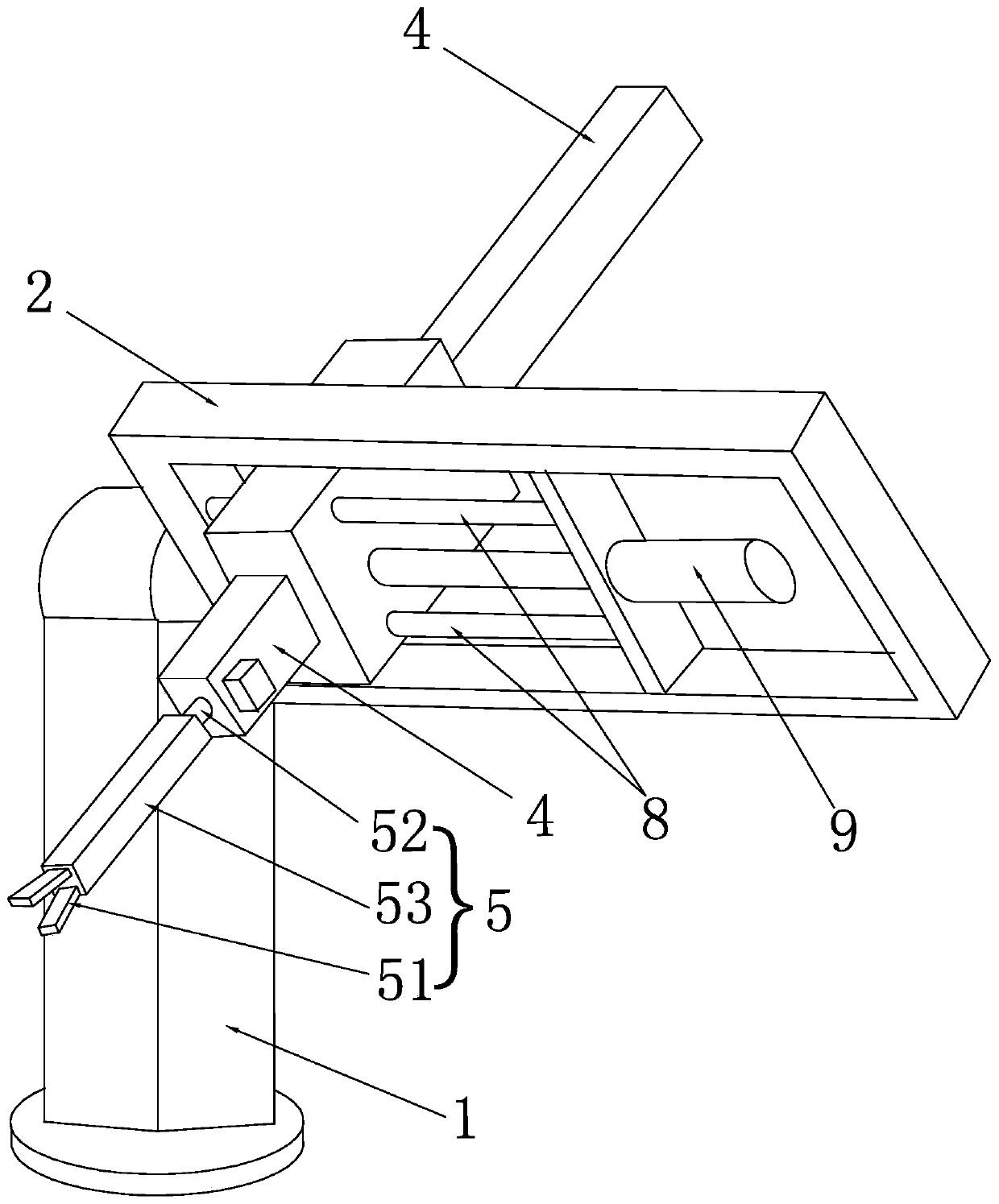

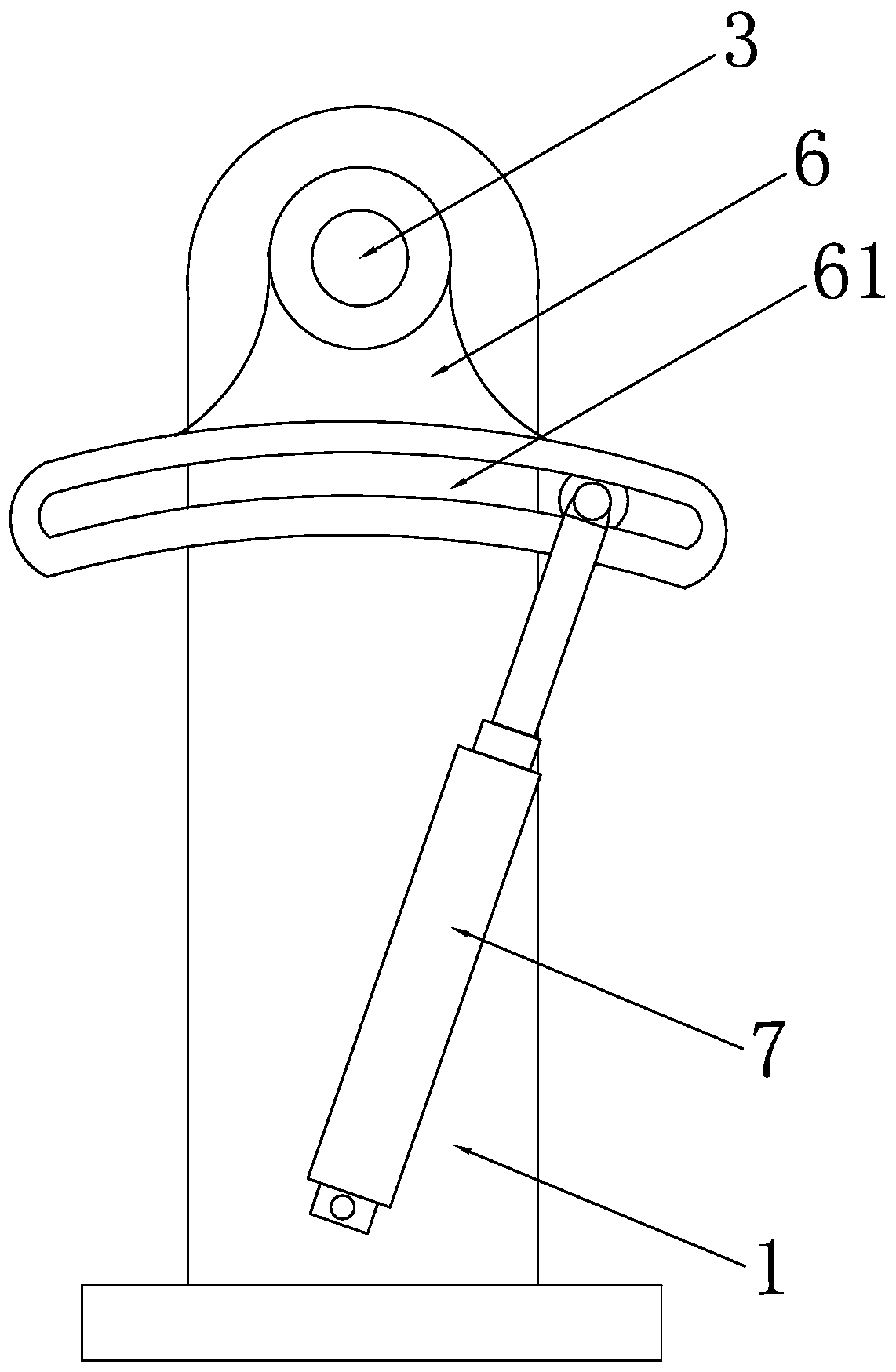

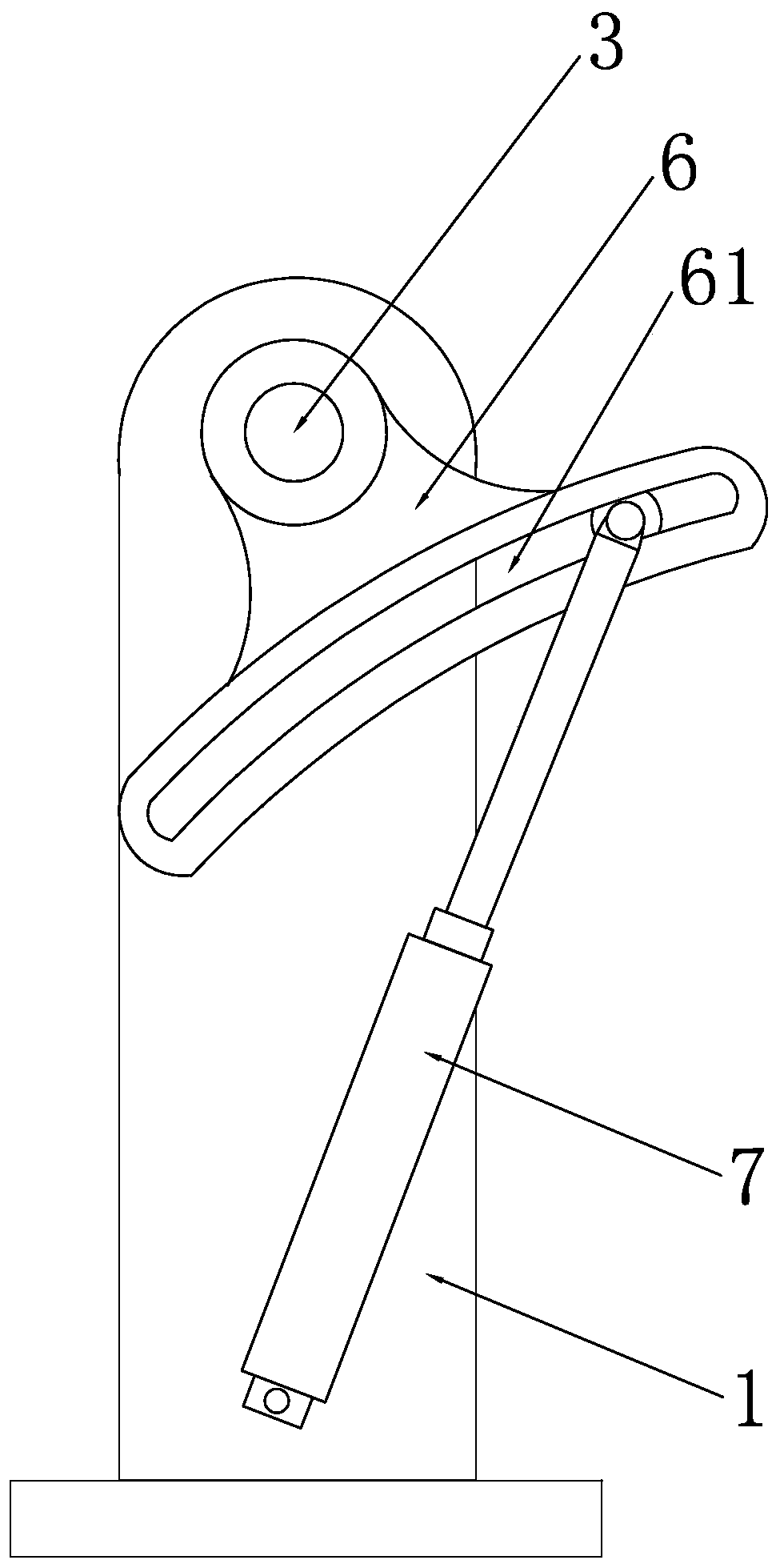

[0019] see figure 1 and figure 2 , an oblique-arm manipulator for in-mold retrieval of the present invention includes a support 1, an overturning table 2 and a gripper assembly 5, the overturning table 2 is provided with a rotating shaft 3, and the rotating shaft 3 is rotatably mounted on the support 1 through a bearing In the upper part, the turning table 2 can turn around the rotation axis 3 relative to the support 1.

[0020] like figure 1 As shown, the turning platform 3 is also provided with a swing arm support that can move along the parallel direction of the rotating shaft 3. The swing arm support is provided with a swing arm 4, and the swing arm 4 can move along its own length direction. The length direction is perpendicular to the rotation axis 3. Two guide rods 8 all parallel to the rotation axis 3 are arranged on the turning platform 2. The swing arm bracket is slidably installed on the two guide rods 8. The power part 9 on the top is driven to drive the swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com