Crankshaft type high-pressure cleaning pump

A technology for high-pressure cleaning of pumps and crankshafts, applied in pumps, multi-cylinder pumps, liquid variable capacity machinery, etc., can solve problems such as damage to related components, short service life, and no product launch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

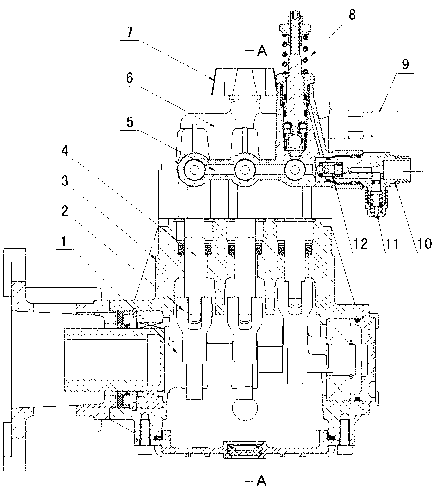

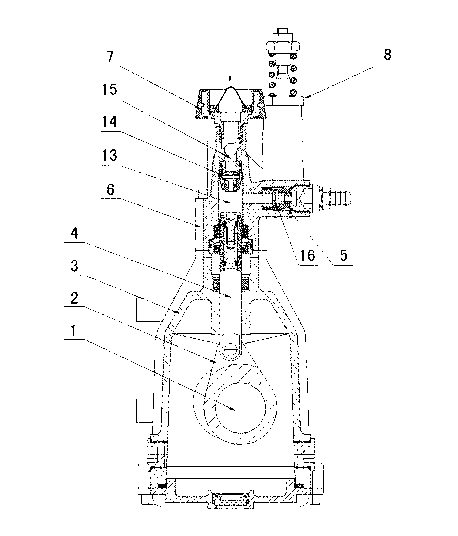

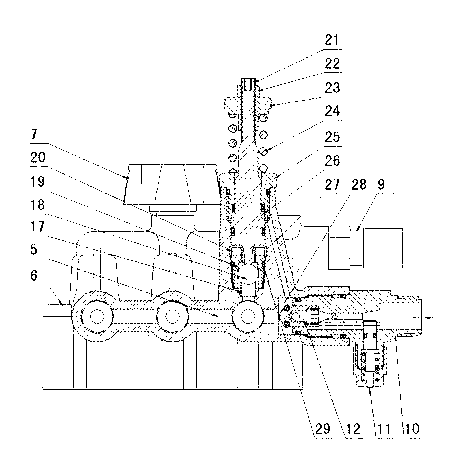

[0014] figure 1 , figure 2 and image 3 As shown, the specific embodiment of the crankshaft type high-pressure cleaning pump created for the present invention includes a box body 3, a crankshaft 1 connected with power, a connecting rod 2, a plunger 4, a pump body 6, a water inlet joint 7, a pressure regulating discharge Load valve 8, high-pressure water outlet joint 10, the pump body 6 is provided with a low-pressure chamber 15, an exchange chamber 13 and a high-pressure chamber 5, the plunger 4 is connected to the exchange chamber 13, and the water inlet joint 7 is connected to the low-pressure chamber 15 A water inlet check valve 14 is installed between the low pressure chamber 15 and the exchange chamber 13, a water outlet check valve 16 is installed between the exchange chamber 13 and the high pressure chamber 6, and the high pressure outlet joint 10 is connected to the water outlet of the high pressure chamber 5 Above, a check valve 12 corresponding to the water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com