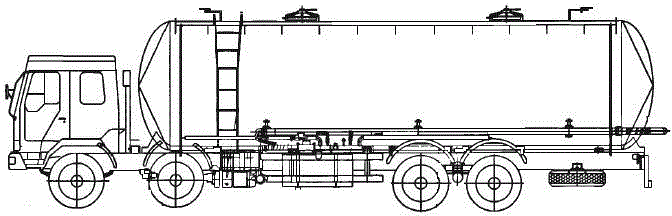

Transport vehicle for powdered and granular materials

A technology for transporting vehicles and materials, which is applied in the field of powder material transporting vehicles, which can solve the problems of unclean unloading and low transportation efficiency, and achieve the effect of convenient maintenance and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

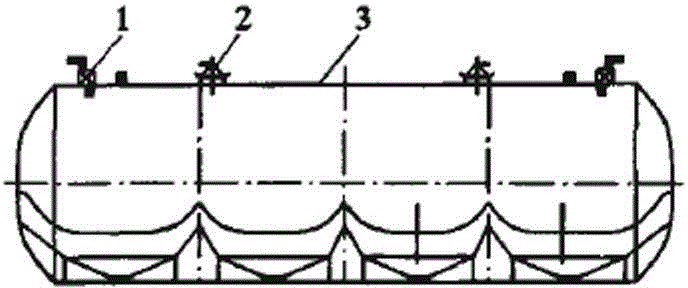

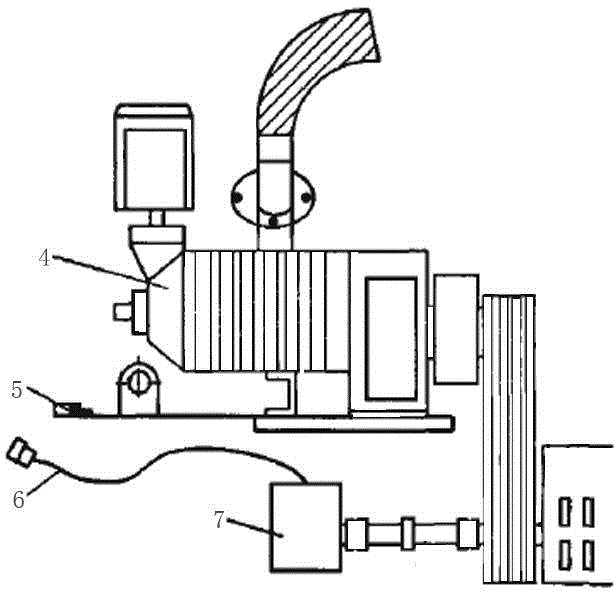

[0014] Powder material transport vehicle, including a sealed tank body 3, a power take-off system, an air intake pipeline and a discharge pipeline, wherein the tank body 3 is a cylinder with an oval tank cover 2 on one side and an exhaust valve on it 1. The power take-off system consists of an air compressor 4, a hand throttle 5, and a power take-off 7, wherein the power take-off 7 is provided with a switch 8. The air intake pipeline is composed of a check valve, a safety valve, a separate air intake valve, a pressure gauge, and an auxiliary blowing pipeline. The unloading pipeline is composed of a main pipe 12, a suction port 8, a large elbow 9, a tank inner flange 10 and a butterfly valve 11.

[0015] Align the feed port of the tanker with the discharge port of the silo, and wait for the car to stop.

[0016] The operator opens the exhaust valves 1 at both ends of the top of the tank body 3 to let off the residual compressed air in the tank, and opens the feed port cover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com