HDPE (High-Density Polyethylene) steel belt reinforced spiral corrugated pipe and production process thereof

A spiral corrugated pipe and production process technology, applied in the field of plastic pipe processing, can solve problems such as poor rigidity, affecting product service life, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

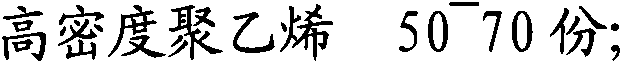

[0019] A HDPE steel strip reinforced spiral corrugated pipe, comprising the following raw materials in parts by weight:

[0020]

[0021] Mix the above raw materials according to the formula ratio, remove the moisture in the raw materials, make the high-density polyethylene raw materials semi-gel, form loose powder, and make the additives uniformly dispersed in the high-density polyethylene raw materials, and the mixing temperature is: The hot mixing temperature is 80°C, and the cold mixing temperature is 70°C.

Embodiment 2

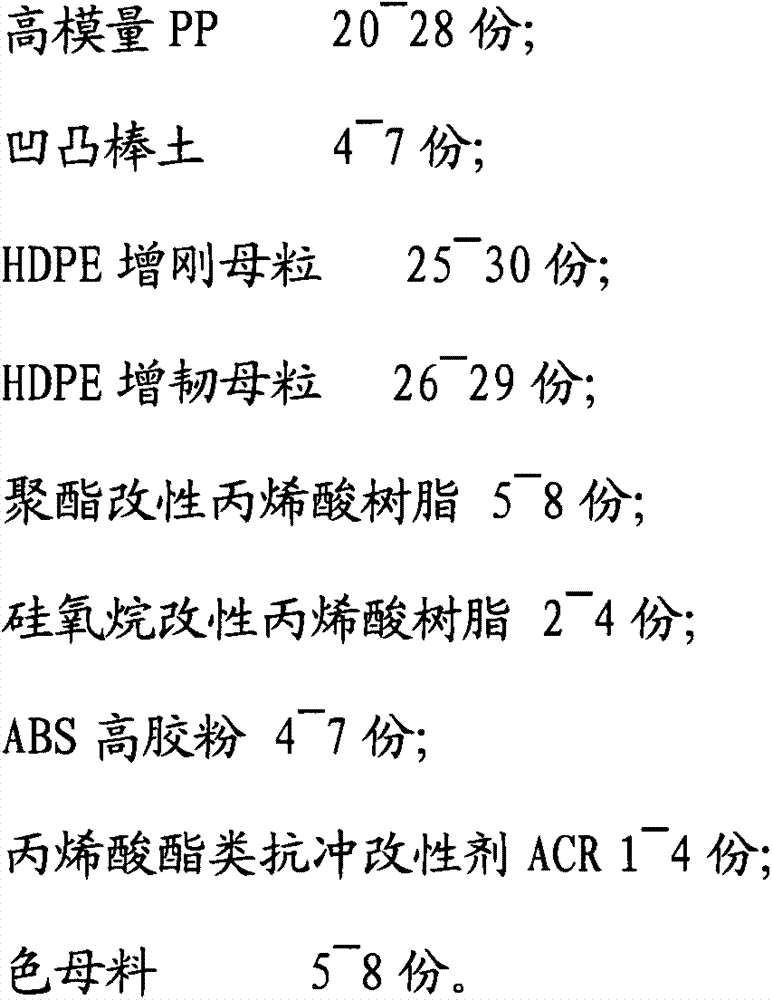

[0023] A HDPE steel strip reinforced spiral corrugated pipe, comprising the following raw materials in parts by weight:

[0024]

[0025] Mix the above raw materials according to the formula ratio, remove the moisture in the raw materials, make the high-density polyethylene raw materials semi-gel, form loose powder, and make the additives uniformly dispersed in the high-density polyethylene raw materials, and the mixing temperature is: The hot mixing temperature is 120°C, and the cold mixing temperature is 80°C.

Embodiment 3

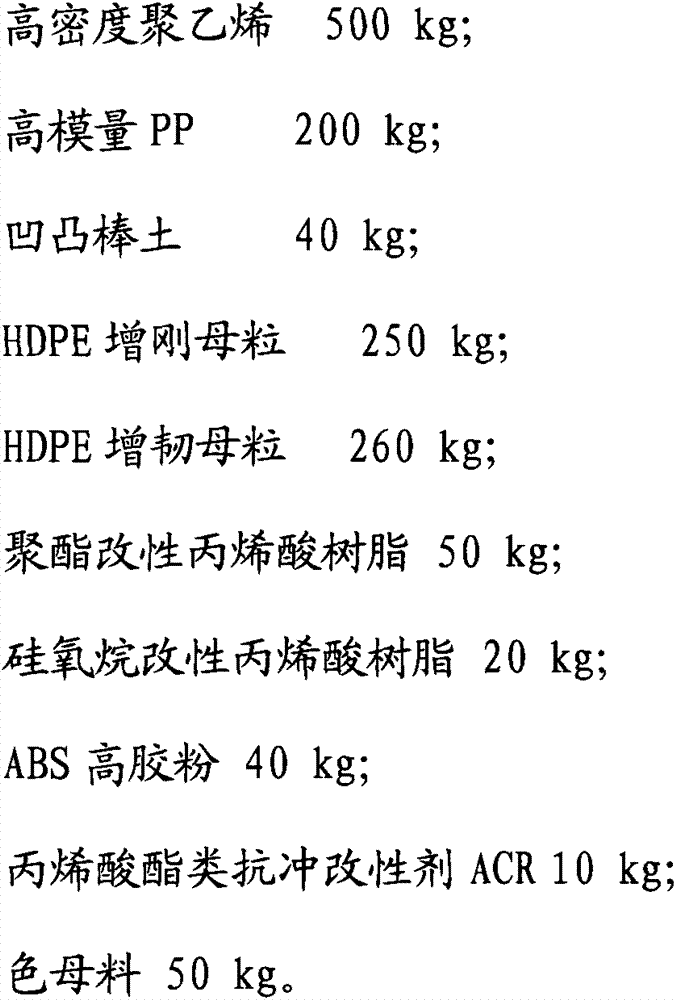

[0027] A HDPE steel strip reinforced spiral corrugated pipe, comprising the following raw materials in parts by weight:

[0028]

[0029]

[0030] Mix the above raw materials according to the formula ratio, remove the moisture in the raw materials, make the high-density polyethylene raw materials semi-gel, form loose powder, and make the additives uniformly dispersed in the high-density polyethylene raw materials, and the mixing temperature is: The hot mixing temperature is 105°C, and the cold mixing temperature is 75°C.

[0031] In the present invention: a kind of production technology of HDPE steel belt reinforced spiral bellows, comprises the following steps:

[0032] The first step, raw material mixing: add high-density polyethylene raw materials, color masterbatch, stabilizer, defoamer, antioxidant and other auxiliary materials into the dry mixer in succession according to the proportion and process, remove moisture, and the materials are fully dried and mixed Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com