Rice husk cleaning, warehousing and conveying production line

A production line and chaff technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of unstable impurity content, large mechanical conveying resistance, and urgency, and achieve improved working environment, high degree of automation, fully functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

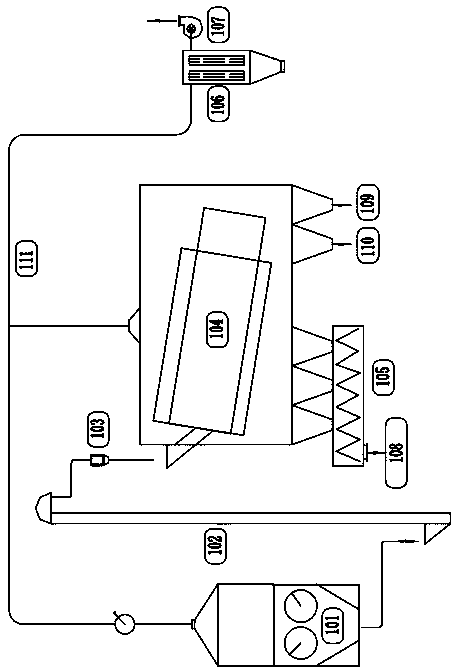

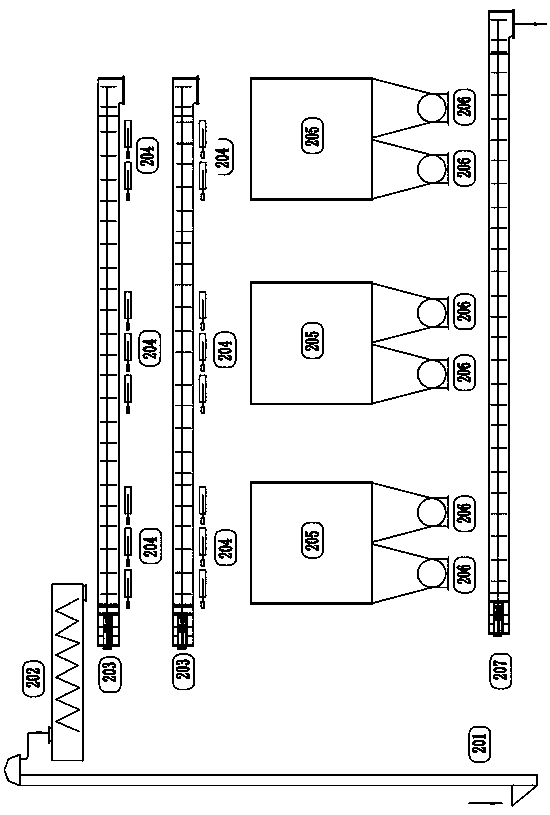

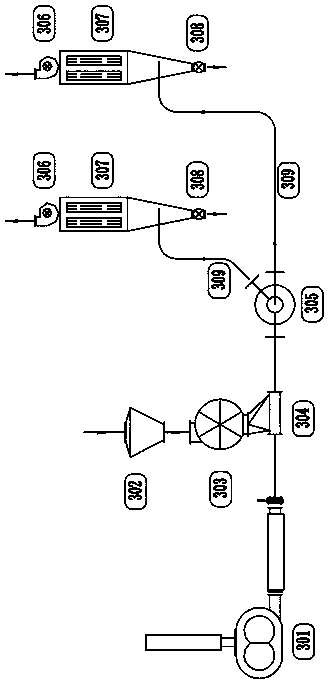

[0029] Such as Figure 1-Figure 4 Shown, chaff cleaning of the present invention, storage and conveyance production line, comprise the cleaning classification workshop section, storage workshop section and wind conveying workshop section that are arranged successively;

[0030] The cleaning and grading section includes a double-screw feeder 101, a first elevator 102, a permanent magnet cylinder 103, a double-cylinder rotary screen 104, and a light miscellaneous collection screw conveyor 105. The outlet of the double-screw feeder 101 is connected to the first lifting The feed port at the lower part of the elevator 102 is connected, the discharge port at the top of the first hoist 102 is connected with the feed port of the double-cylinder rotary screen 104 through the permanent magnet cylinder, and the bottom of the double-cylinder rotary screen 104 is provided with a small and light trash discharge port 108, large miscellaneous discharge port 109 and clean chaff discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com