Hydraulic car dumper

A dumper and hydraulic technology, applied in the field of hydraulic dumpers, can solve problems such as inability to operate containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

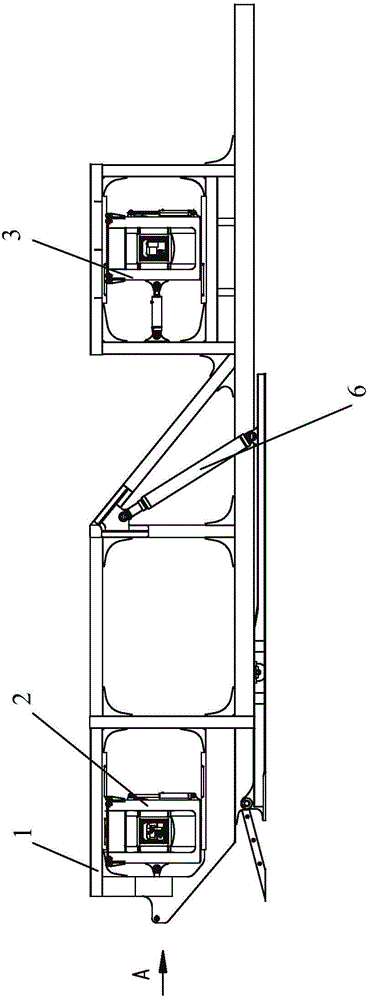

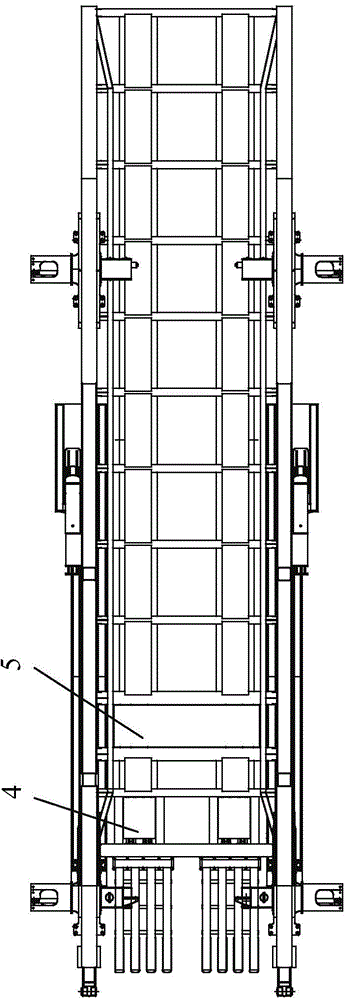

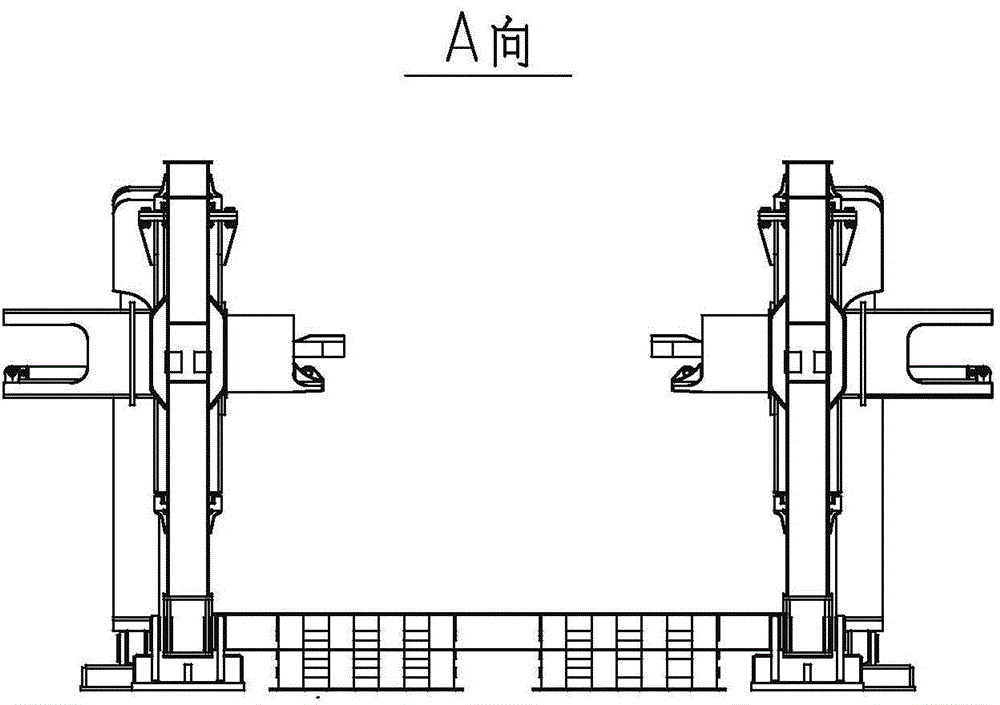

[0023] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

[0024] See Figures 1A to 1C , The hydraulic dumper in this embodiment includes an overturning platform 1 , two sets of tail arm mechanisms 2 , two sets of end latch mechanisms 3 , a frame jacking mechanism 5 and a platform overturning mechanism 6 . Preferably, the hydraulic dumper may also include a wheel stopper mechanism 4 .

[0025] Turning platform 1 is the main structural part of the hydraulic dumper. One end of turning platform 1 is hinged on the base, and the rest of the mechanisms (such as two groups of tail arm mechanisms 2, two groups of end latch mechanisms 3, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com