Small particle material squeezing material-unloading machine

A small particle, unloader technology, applied in the direction of unsealing, packaging, transportation and packaging of objects, can solve problems such as residue, waste, waste of resources, etc., and achieve the effect of saving small particle materials, reducing manufacturing costs, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

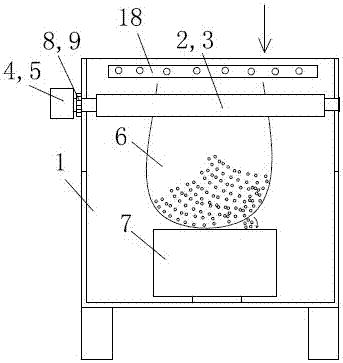

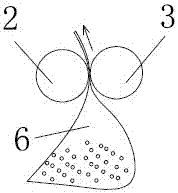

[0020] Such as figure 1 As shown, the small particle material extrusion unloading machine includes an open box body 1, and a first squeeze roller 2 and a second squeeze roller 3 arranged at the top position of the open box body 1, the first squeeze roller 2 One or both of them are connected to the rotating handle 4 or the rotating power source 5 in the second extrusion roller 3; as image 3 As shown, the flexible bag 6 containing the small particle material is hung on the first squeeze roller 2 or the second squeeze roller 3, and the small particle material in the flexible bag is extruded and unloaded by these two squeeze rollers.

[0021] In the above embodiments, the bottom of the open box 1 is provided with a detachable collecting device 7 . The first squeeze roller 2 and the second squeeze roller 3 are meshedly connected by a pair of paired first gear 8 and second gear 9 at one end thereof, so that when the two pressure rollers squeeze the material in the flexible bag , ...

Embodiment 2

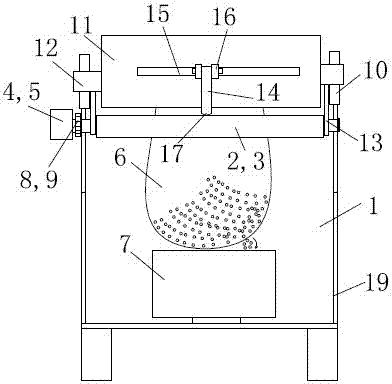

[0023] Such as figure 2 As shown, the difference from the small particle material extruding discharger of embodiment 1 is that one of the first extruding roller 2 and the second extruding roller 3 of the extruding machine of the present embodiment is fixedly connected to On the open box body 1, the other is connected to the top position of the open box body 1 by a vertical slide rail 10 slidably up and down; and the vertical slide rail 10 is fixedly arranged on the top of the open box body 1, The two ends of the first squeeze roller 2 or the second squeeze roller 3 are connected to slide on the vertical slide rail 10 through a sliding support 11, which can better put the material into the bottom of the box body and facilitate disassembly.

[0024] In the above embodiment, the two ends of the sliding support 11 are respectively connected to slide on the vertical slide rail 10 through a slider 12, and at the same time, the sliding support 11 is provided with a downward protrudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com