Press moveable platform for elastic element unloading

A technology of moving workbench and elastic components, which is applied in the field of presses, can solve the problems of many links in the guiding mechanism, large lifting stroke of the workbench, affecting the appearance of the press, etc., and achieves simple structure, small deformation, and long glass fiber reinforced response The effect of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

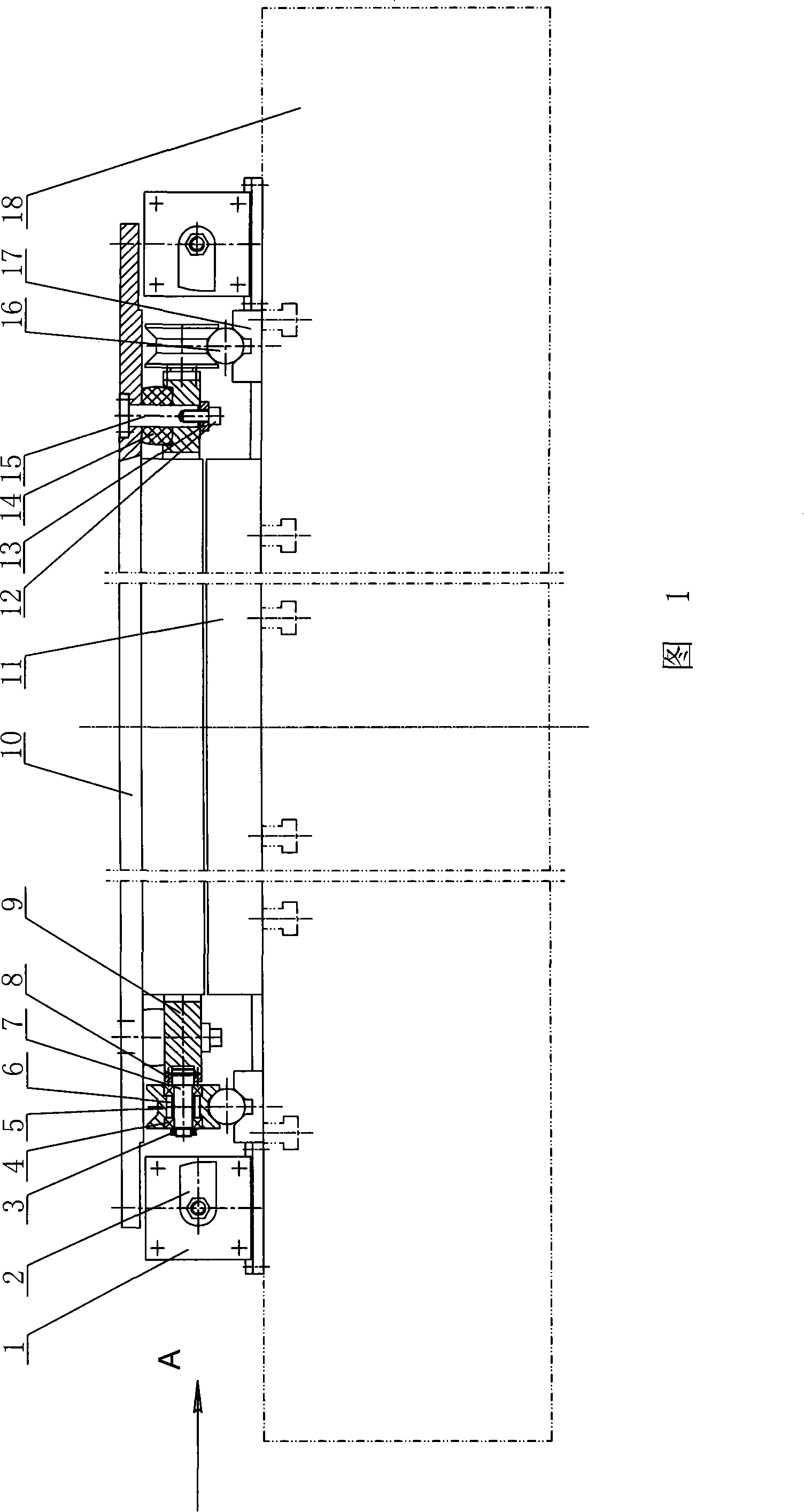

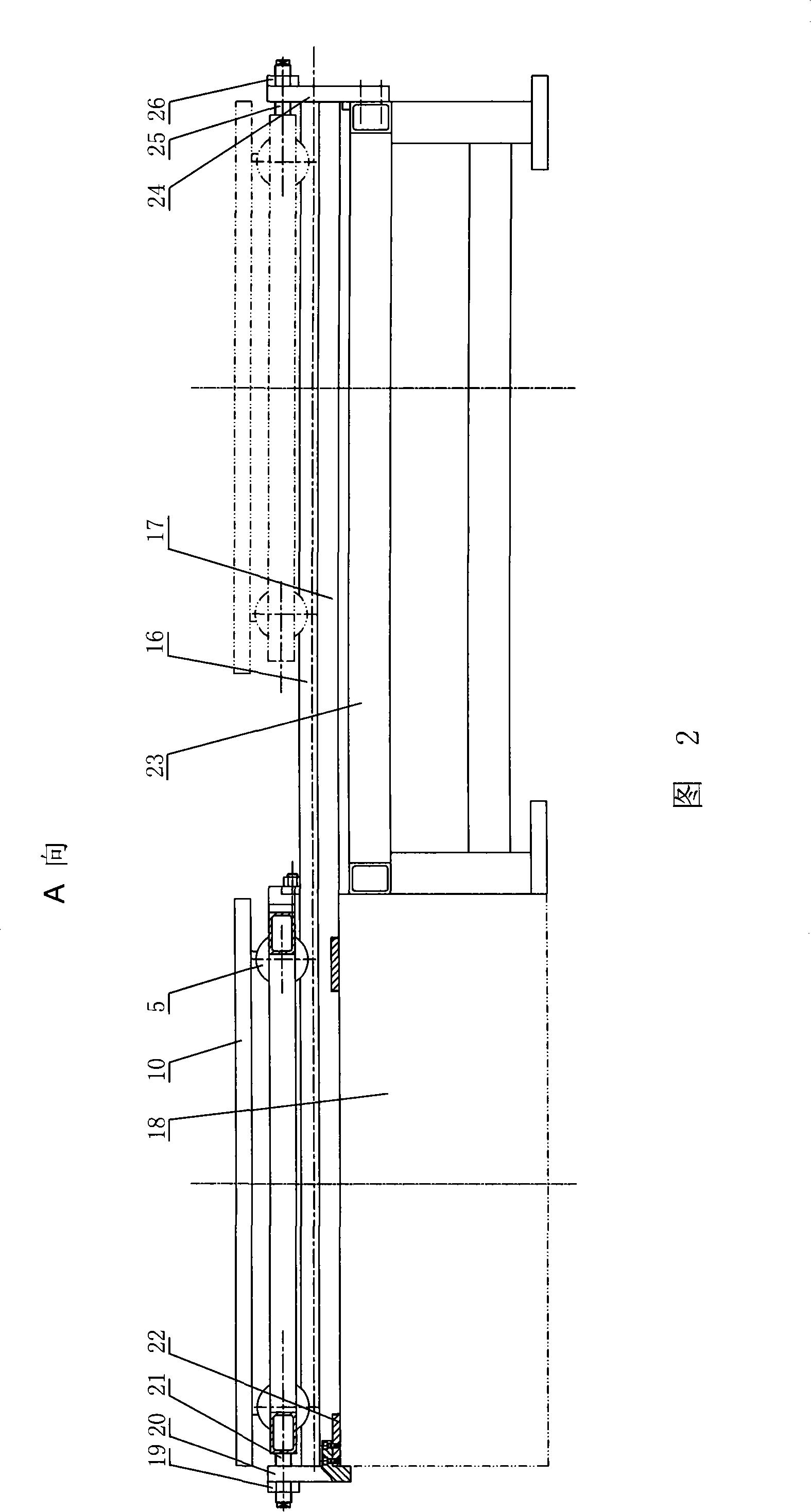

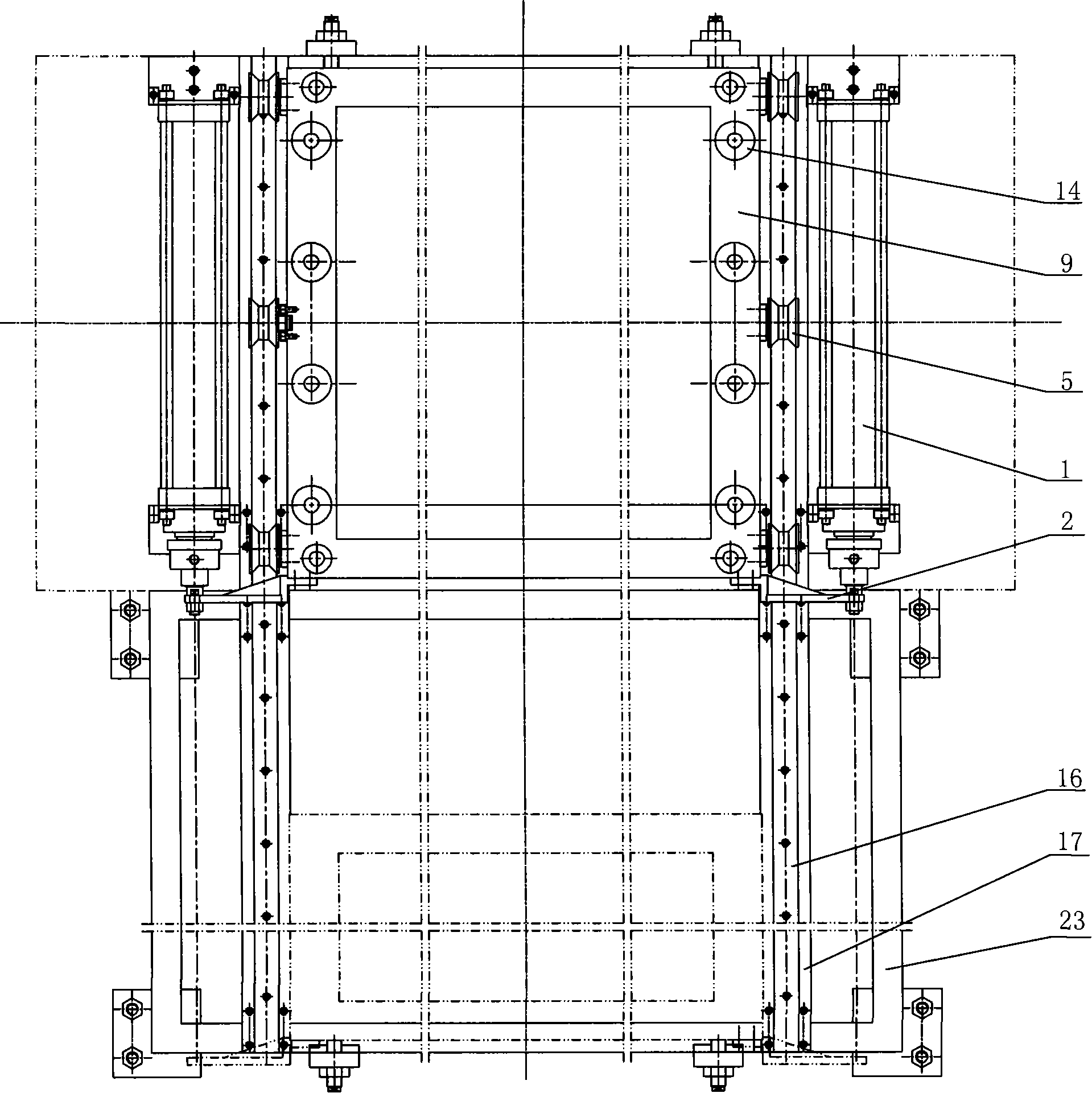

[0034] As shown in the figure, the movable workbench of the press for unloading the elastic element includes a worktable 10, a movable bracket 9 is arranged under the worktable 10, and a guide rod 15 is used between the worktable 10 and the movable bracket 9 Guide, the guide rod 15 is set with a pre-compressed elastic element 14, the elastic element 14 can be a polyurethane rubber plate or a coil spring, a disc spring, etc. 9, in order to realize the pre-compression of the elastic element 14, the lower end of the guide rod is provided with a baffle 13, the baffle 13 is attached to the lower side of the moving bracket 9, the screw 12 passes through the baffle 13 and is connected with the lower end of the guide rod, and the screw is tightened 12. The elastic element 14 can be compressed to realize the pre-compression of the elastic element 14. The pre-compression amount of the elastic element 14 should ensure that its load-bearing capacity can be enough to hold up the worktable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com