Split type horizontal moving dump carriage and dump truck with same

A split-type, carriage technology, applied in the direction of loading and unloading vehicles, motor vehicles, transport objects, etc., can solve the problems of long unloading cycle, low automation efficiency, and unloading margin, so as to ensure unloading automation and safety, and save manpower. , Improve the effect of unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

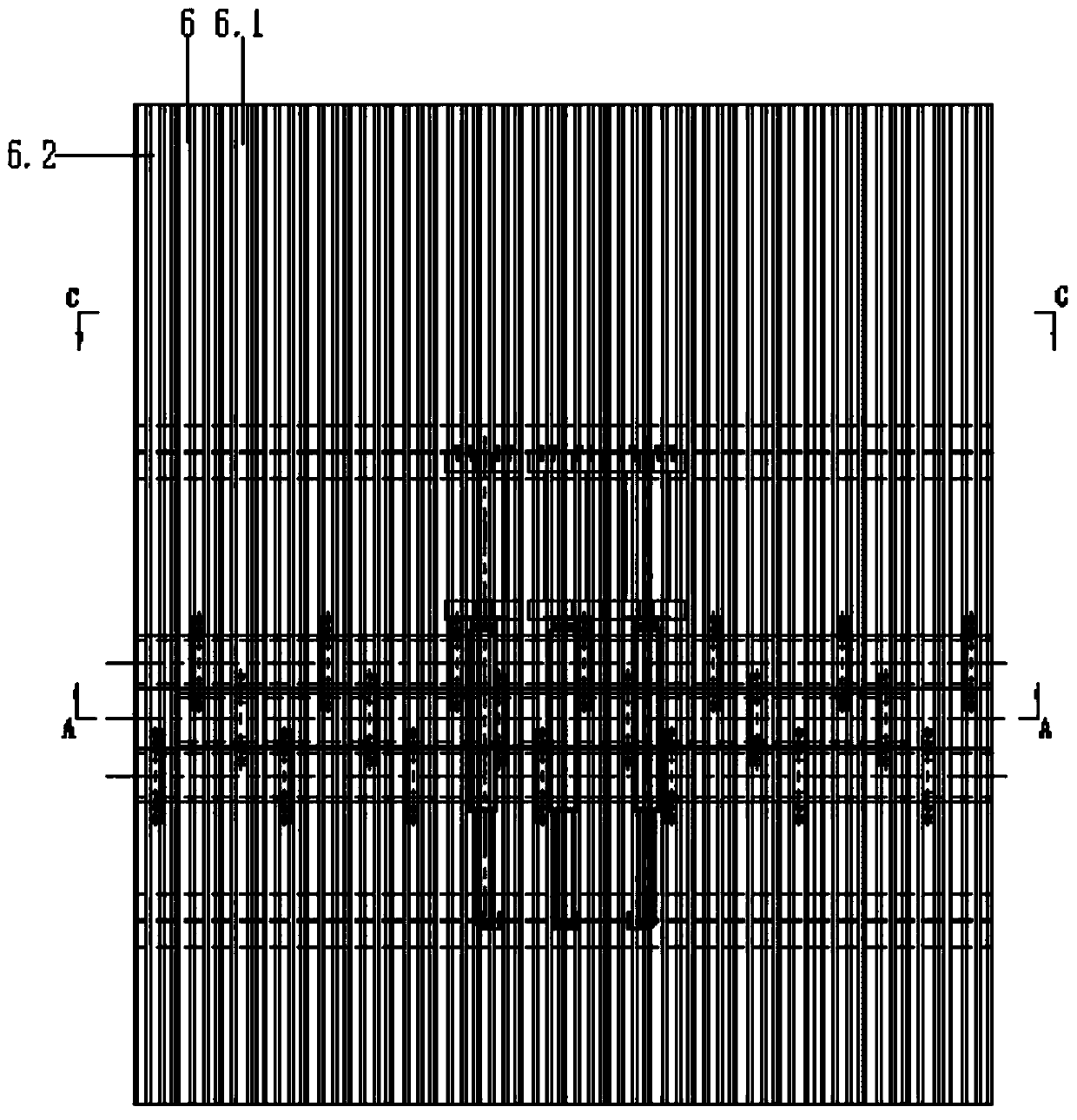

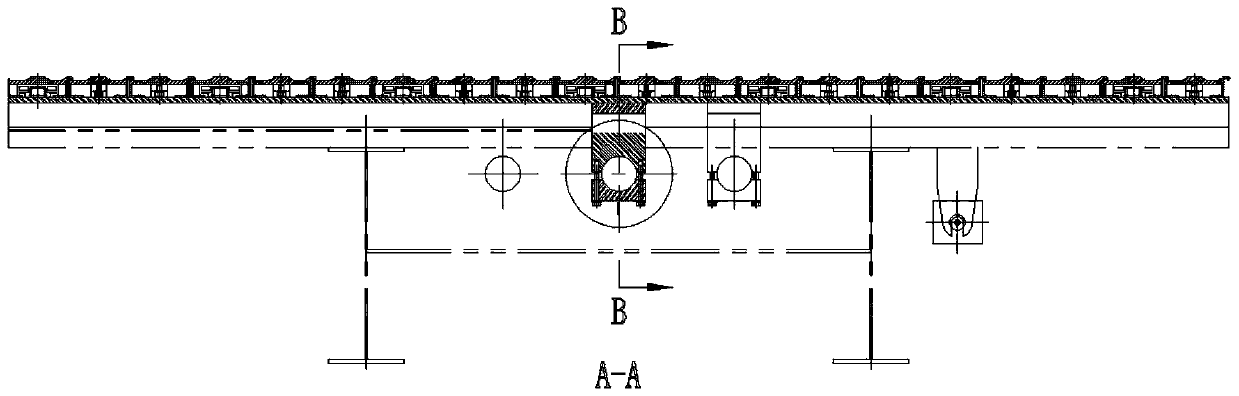

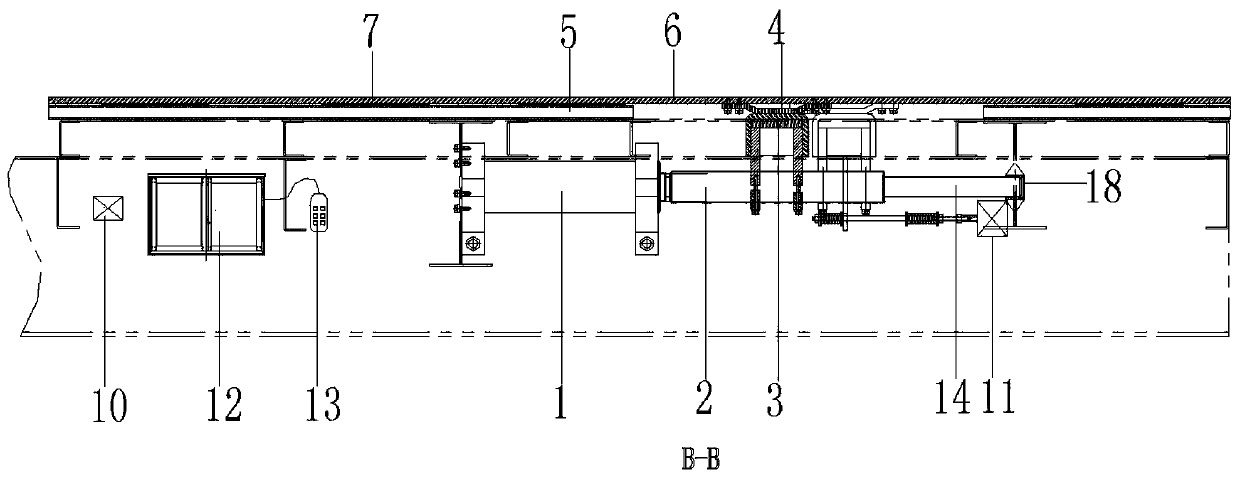

[0040] Example 1, such as Figure 1-10As shown, a split-type translational dump car includes a loading platform, and the loading platform includes several groups of sliding bodies that are snap-connected, and each group of sliding bodies includes first sliding plate grooves 6 that are snap-connected to each other. , the second sliding plate groove 6.1 and the third sliding plate groove 6.2, the first guide track 5 matching with it is provided under the first sliding plate groove 6, and the second sliding plate groove 6.1 is provided with The second guide track that cooperates with it is provided with a third guide track that cooperates with it under the third slide plate groove 6.2, and a drive that drives it on the first guide track is provided below the first slide plate groove 6. 5, the first power device that slides on the top is provided with a second power device that drives it to slide on the second guide track under the second slide plate groove 6.1, and a Drive the t...

Embodiment 2

[0061] Embodiment 2, the present invention also provides a dump truck, comprising the split-type translational dump truck of the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com