Telescopic folding type material conveying device and transport ship

A conveying device and folding technology, which is applied in ship accessories, transportation and packaging, cargo handling equipment, etc., can solve the problems of poor stability, poor rigidity, small space occupation, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

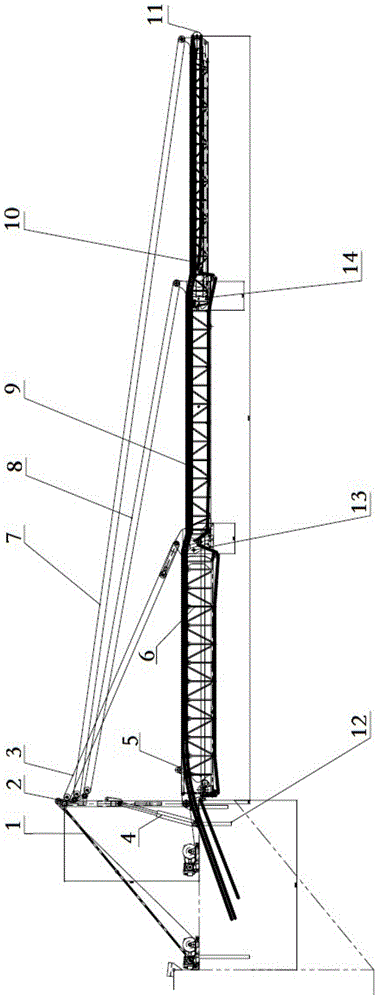

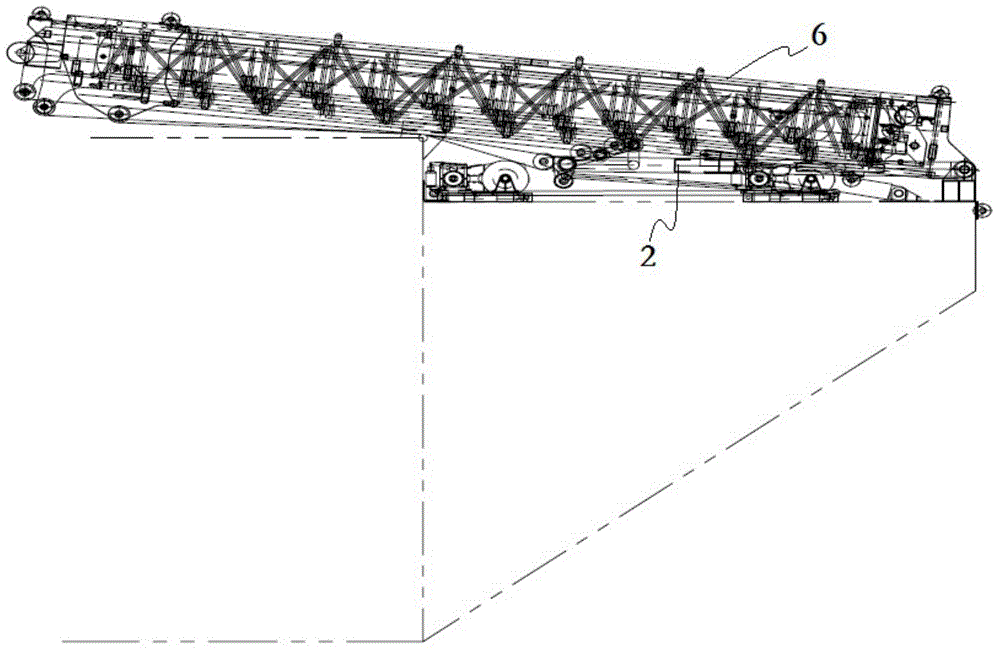

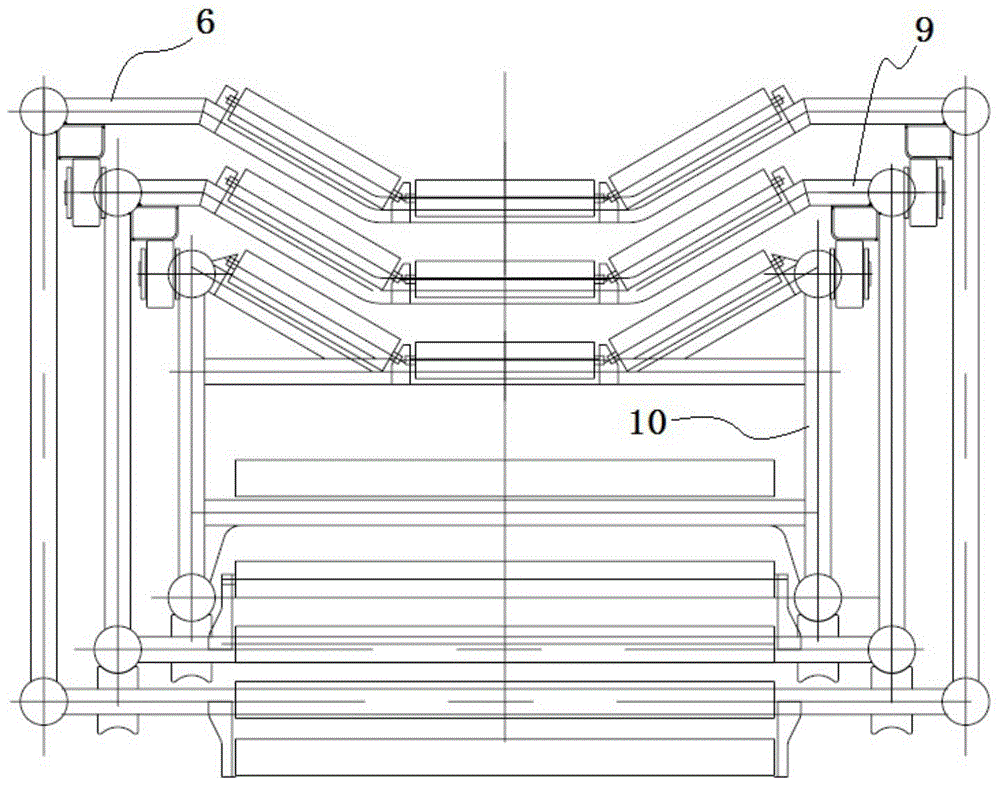

[0028] A telescopic and folding material conveying device, such as figure 1 As shown, it includes a gantry frame seat and a conveying frame seat, a gantry frame 2 mounted on the gantry frame seat and a conveying arm hinged on the conveying frame seat; Folding turning mechanism 4; the delivery arm includes three booms, namely the main arm 6, the first telescopic arm 9 and the second telescopic arm 10; the first telescopic arm 9 can be extended or retracted relative to the main arm 6 , the second telescopic arm 10 can extend or retract relative to the first telescopic arm 9 . Between the gantry 2 and the main arm 6, as well as between the gantry 2 and the telescopic arms 9, 10 at all levels, there are devices that drive the main arm 6 and the telescopic arms 9, 10 at all levels to move closer to the gantry 2. Or separated main boom luffing mechanism 3 and rope wheel mechanism, the main boom luffing mechanism 3 is used to drive the main boom 6 to move closer to or separate from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com