PE (Polyethylene) composite spiral corrugated pipe and processing method thereof

A technology of a spiral corrugated pipe and a processing method, which is applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of poor rigidity, easy breakage, poor pipe ring stiffness and creep resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

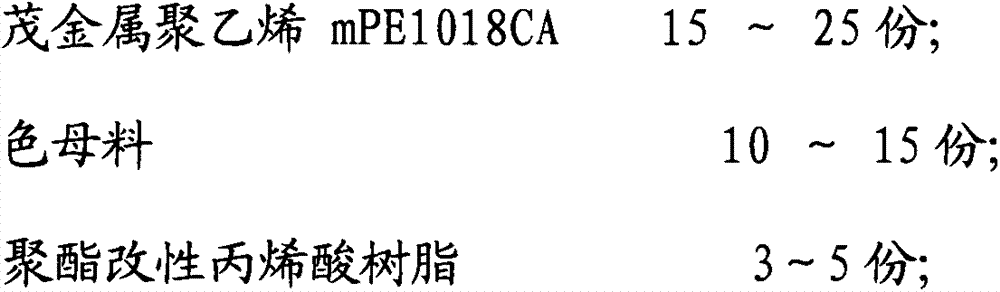

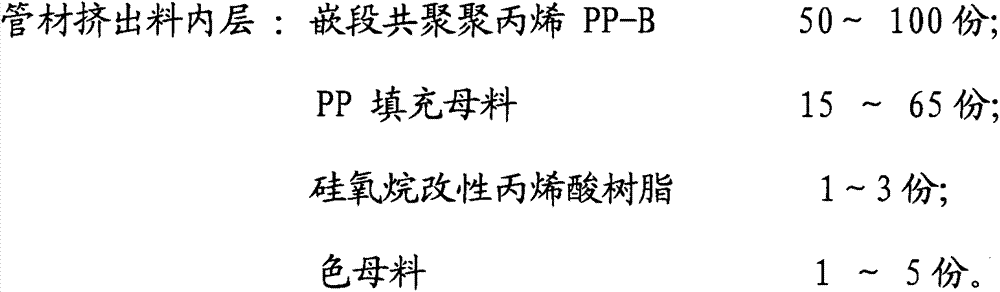

[0018] A PE composite spiral corrugated pipe, the formula of the PE composite spiral corrugated pipe consists of raw materials with the following weights:

[0019]

[0020]

Embodiment 2

[0022] A PE composite spiral corrugated pipe, the formula of the PE composite spiral corrugated pipe consists of raw materials with the following weights:

[0023]

[0024]

Embodiment 3

[0026] A PE composite spiral corrugated pipe, the formula of the PE composite spiral corrugated pipe consists of raw materials with the following weights:

[0027]

[0028]

[0029] In the present invention, a processing method of PE composite spiral corrugated pipe comprises the following steps:

[0030] The first step, raw material mixing: Add PE raw materials and other auxiliary materials into the drying mixer according to the proportion and process, and remove moisture. After the materials are fully dried and mixed, they enter the hopper of the extruder, and the drying temperature is less than 80 degrees;

[0031] The second step, the extruder part: when the screw rotates in the barrel, the PE mixture is plasticized and pushed to the machine head, so as to achieve the purpose of compaction, melting, mixing and homogenization, exhaust and dehydration;

[0032] The third step, the extrusion die part: after compaction, melting, mixing and homogenization of PE, the subse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com