Rolling type internal combustion engine

An internal combustion engine, a new type of technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as complex structures, and achieve the effects of high energy conversion rate, simple structure, and large force arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

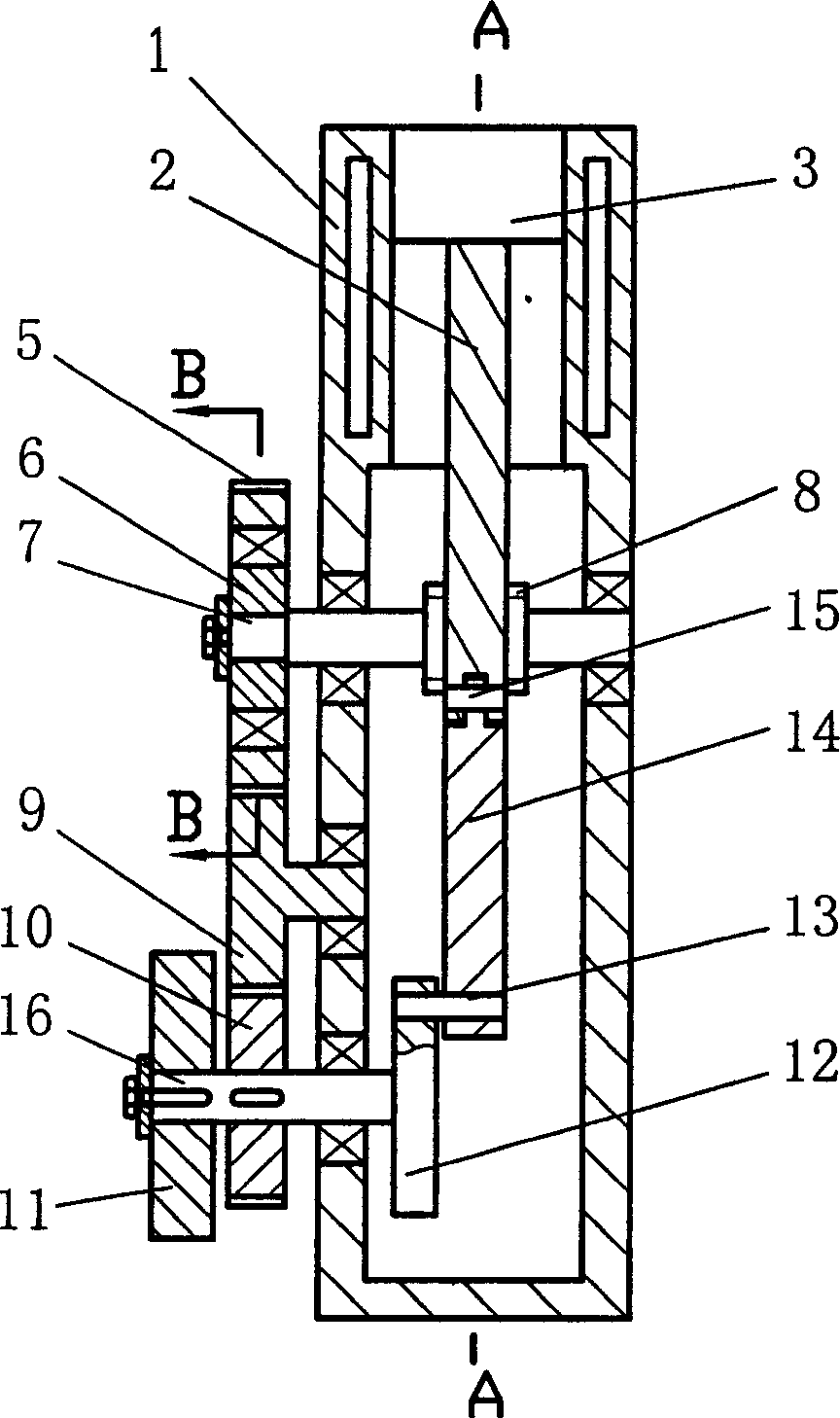

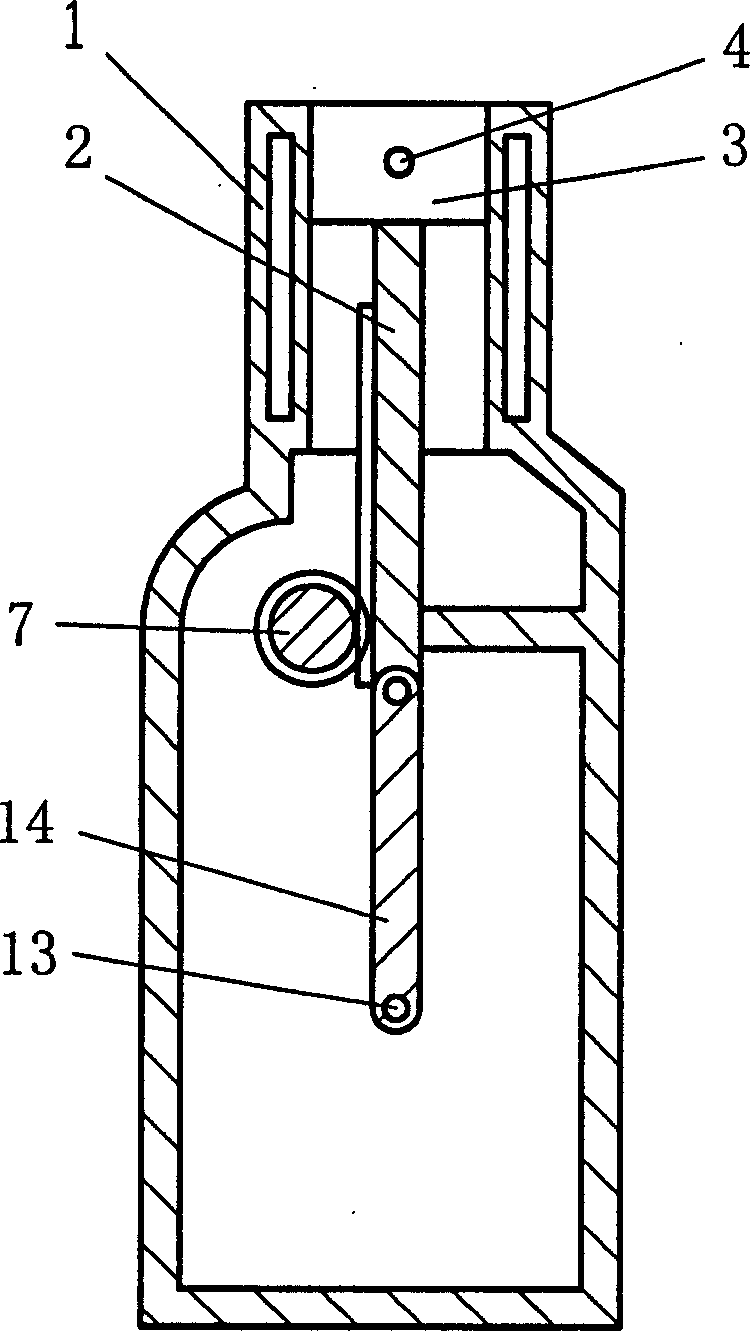

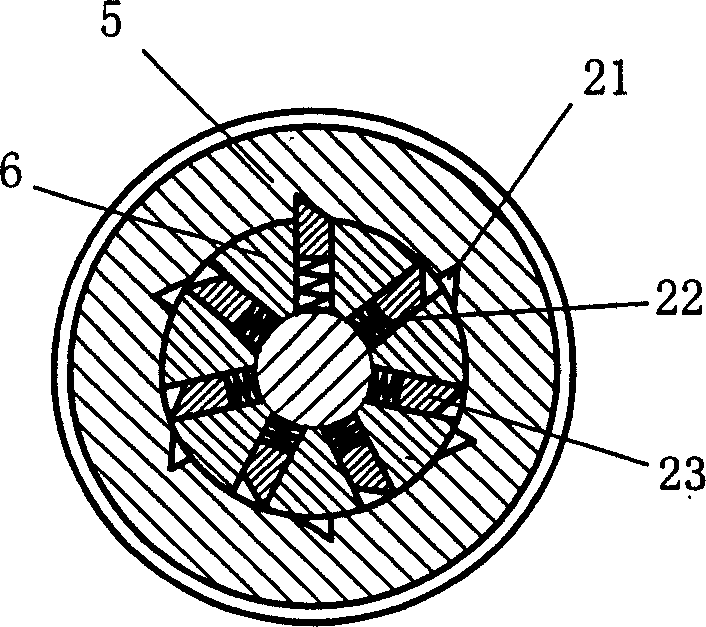

[0025] see figure 1 , figure 2 , image 3 Shown is the first embodiment of the new rubbing internal combustion engine of the present invention, which includes a gas distribution device, an intake and exhaust device, a fuel supply system, a lubrication system, a cooling system, a cylinder block 1, a piston 3, a power transmission mechanism, an unloading The force device, the piston 3 is arranged in the inner cavity of the upper end of the cylinder 1. The power transmission mechanism includes a push rod 2, a ratchet shaft 7, an inner wheel 6, a ratchet mechanism, a ratchet 5, and a transition gear shaft 9. The piston 3 is fixed on the upper end of the push rod 2 through the piston pin 4, a rack is provided on one side of the push rod 2, the ratchet shaft 7 is supported on the cylinder body 1 through a bearing, and the right outer cylindrical surface of the ratchet shaft 7 is An external tooth 8 is arranged on the top, and this external tooth 8 meshes with the rack on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com