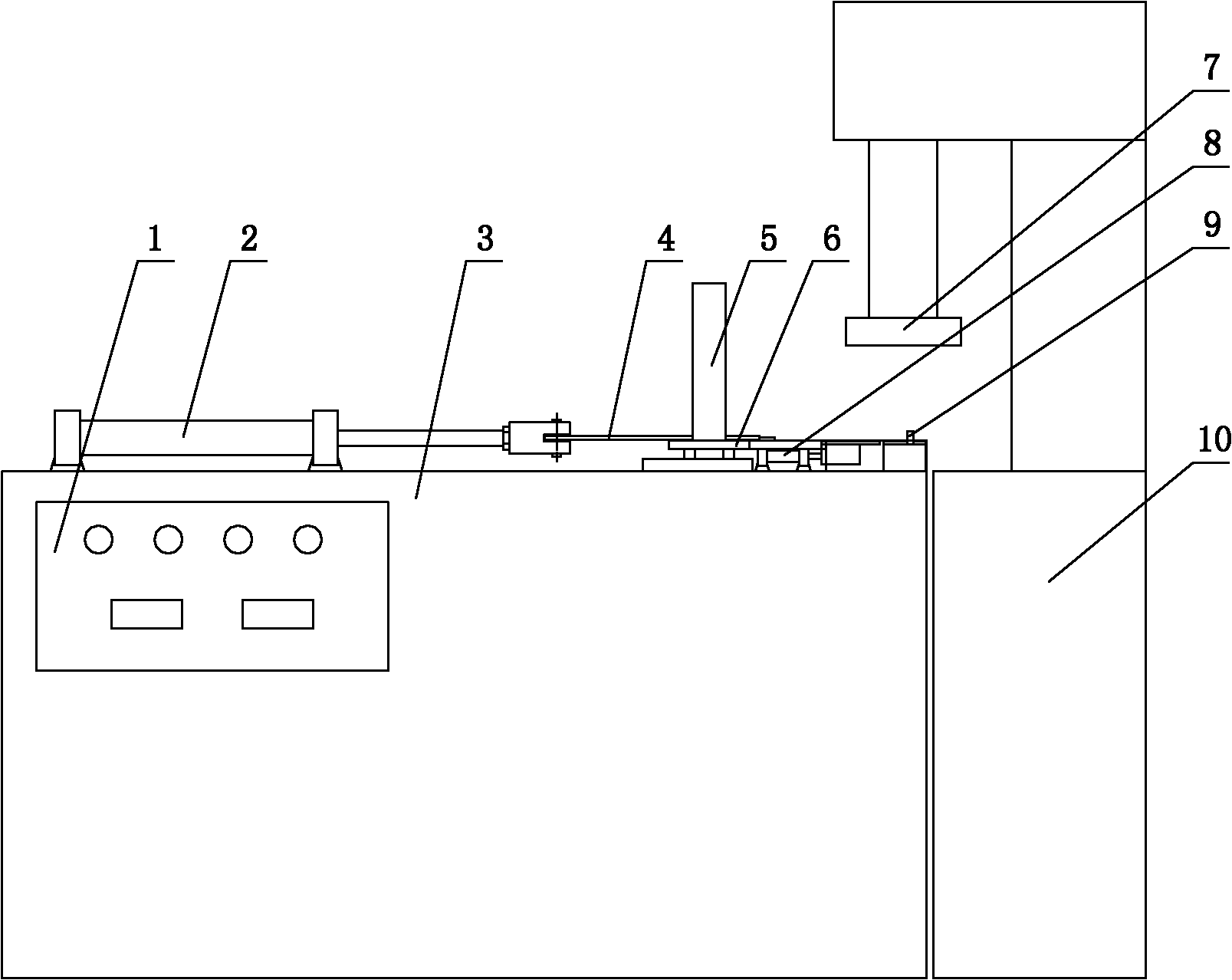

Automatic feeding device

A technology of automatic feeding and feeding cylinders, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of slow manual feeding, large occupation of human resources, and high labor intensity of workers, so as to shorten production time and reduce production The effect of high cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

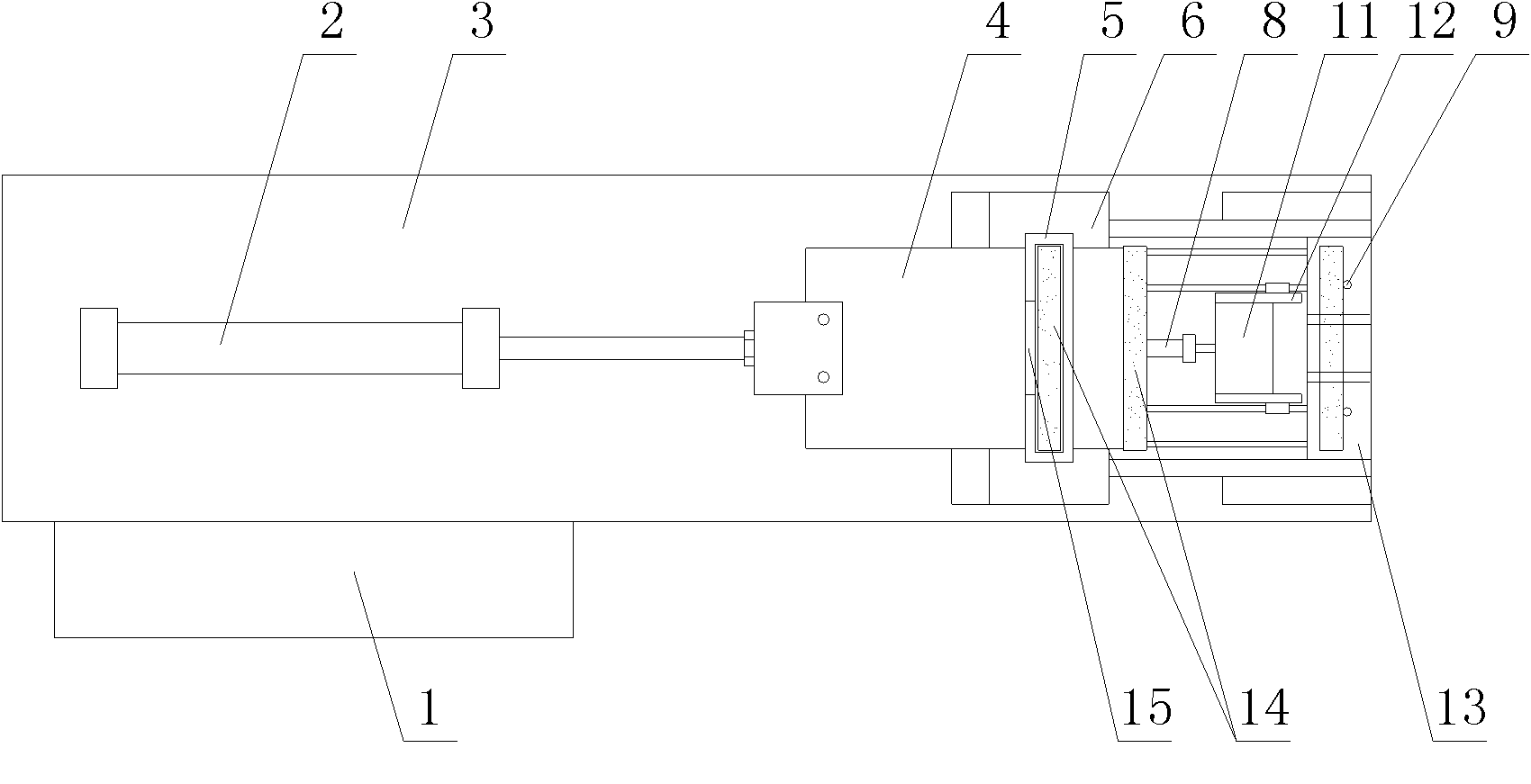

[0019] An automatic feeding device, including a base 3, a feeding box 5 and a feeding cylinder 2, the feeding box is vertically installed on the upper surface of the base, and a longitudinal feeding groove is made inside the feeding box, for the convenience of picking and placing Workpiece, one side of this feeding groove is made opening 15. Between the lower bottom surface of the feed box and the base, a horizontal channel communicating with the feed trough is formed. Since the feed box is usually installed on the base by a mounting frame 6, the distance between the bottom surface of the feed box and the mounting frame A horizontal channel can be formed between them.

[0020] A feed cylinder is installed on the upper surface of the base of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com