Device for detecting axial clearance and radial clearance of joint bearing

A joint bearing and radial clearance technology, which is applied in the direction of measuring devices, mechanical bearing testing, instruments, etc., can solve problems such as unsuitable joint bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

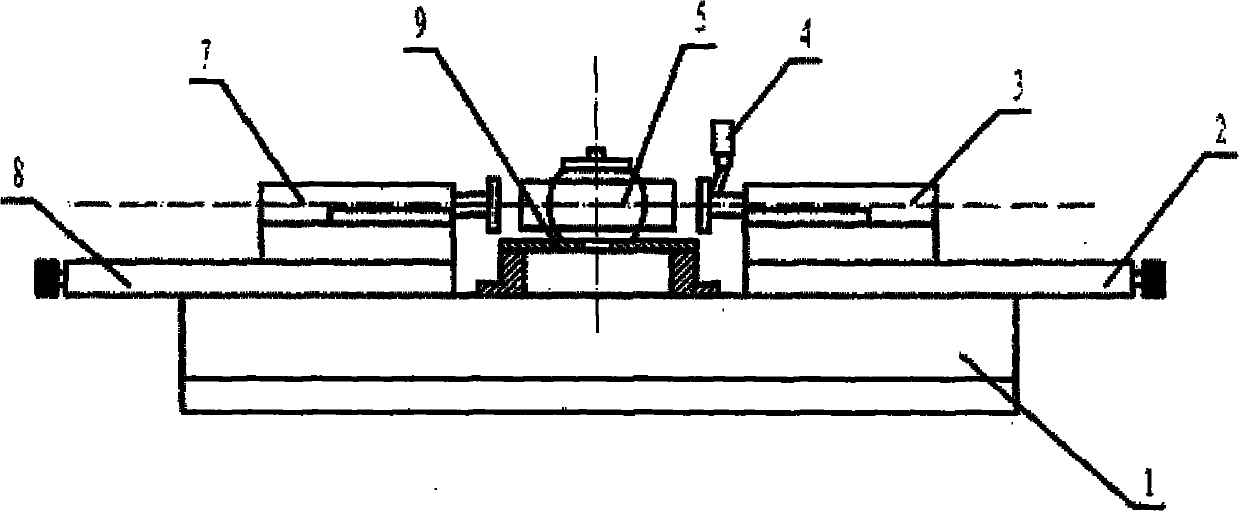

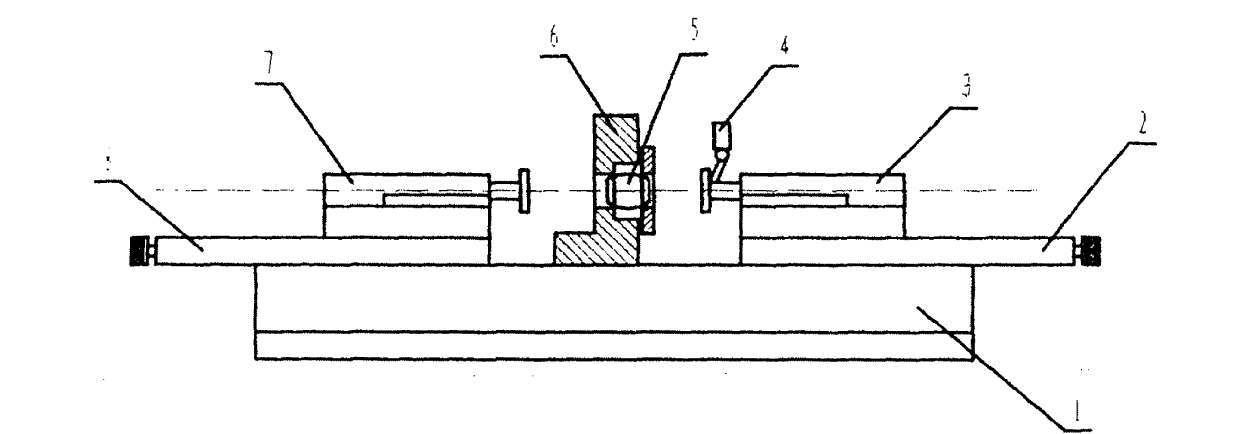

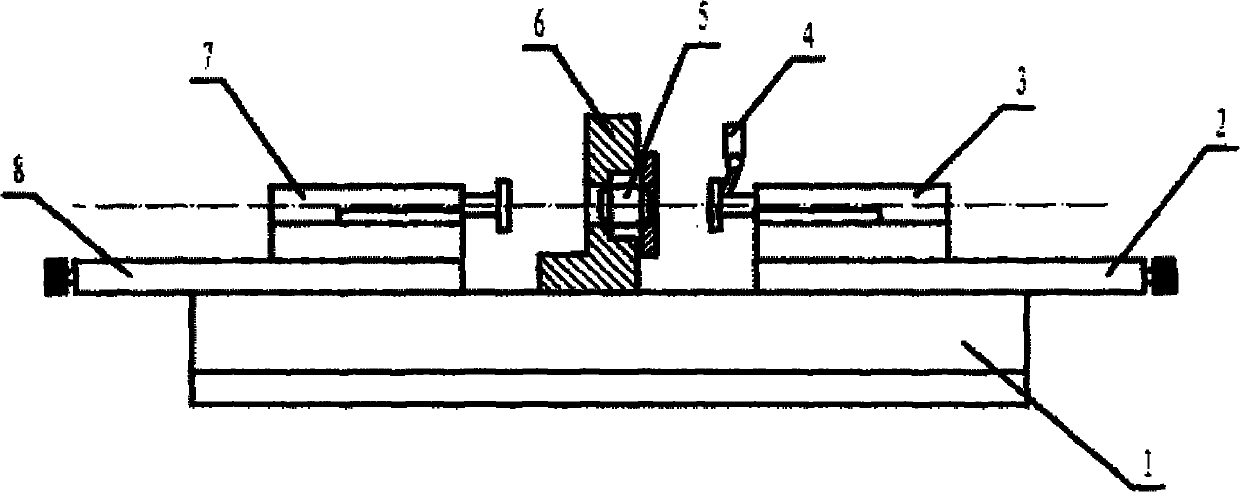

[0013] When measuring the axial clearance of the joint bearing 5, the bearing fixture 6 for measuring the axial clearance installs the joint bearing 5 between the dynamometer 3 and the dynamometer 7, and the dynamometer 3 is installed on the loading slide 2, and the force is measured The meter 7 is installed on the unloading slide 8, the loading slide 2 and the unloading slide 8 are installed on the frame 1; the clearance measuring instrument 4 is fixed on the frame 1. During the measurement, the unloading slide 8 is manually driven, and the dynamometer 7 is driven to apply a specified load to the inner ring of the spherical plain bearing 5 under test, so that the inner ring of the spherical plain bearing 5 moves to the right side of the bearing. Then manually drive the loading slide 2 on the right side, and drive the dynamometer 3 to lean against the inner ring of the joint bearing 5. At this time, clear the clearance measuring instrument 4 and manually drive the unloading sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com