Method for rein forcing concrete structure by top push type prestress carbon fibre cloth and use

A carbon fiber cloth and prestressing technology, which is applied in building maintenance, building structure, construction, etc., can solve the problems of easy overall failure, popularization and application, change of shape size, and inconspicuous bearing capacity, so as to achieve easy guarantee of reinforcement quality and reduce structure Reliable effect of deformation and anchorage measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

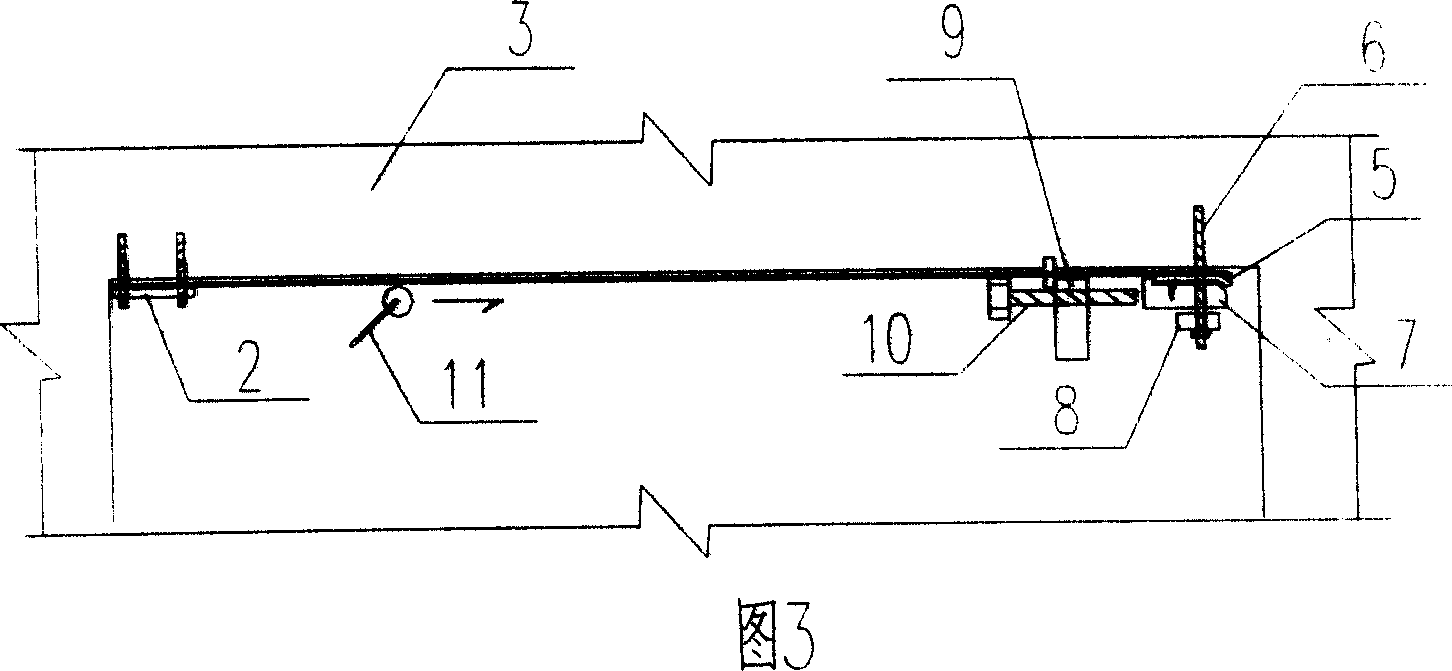

[0023] Below in conjunction with accompanying drawing, the present invention is further described, and this construction method is very clear to being engaged in the professional people of structural reinforcement.

[0024] a. Repair and smooth the surface of the reinforced component (3) first:

[0025] Remove the inferior layer of the reinforced member (3), repair it, and polish it to be smooth without leaving grooves.

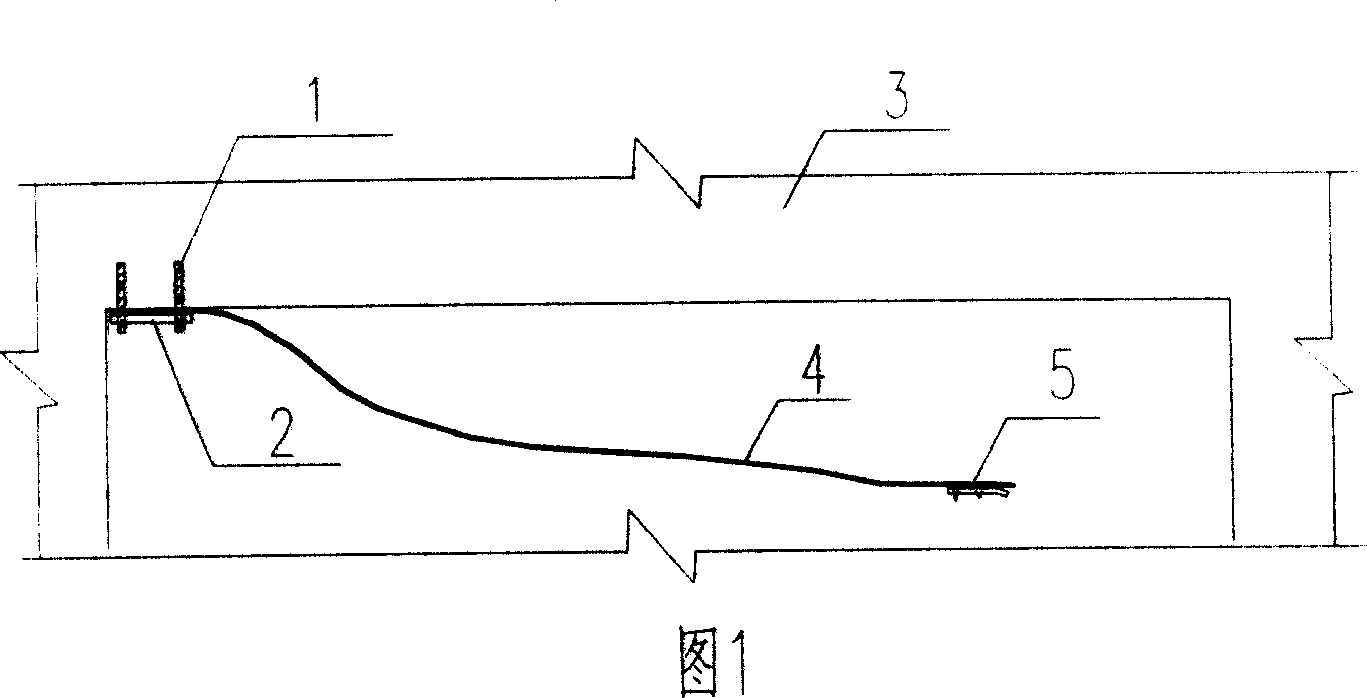

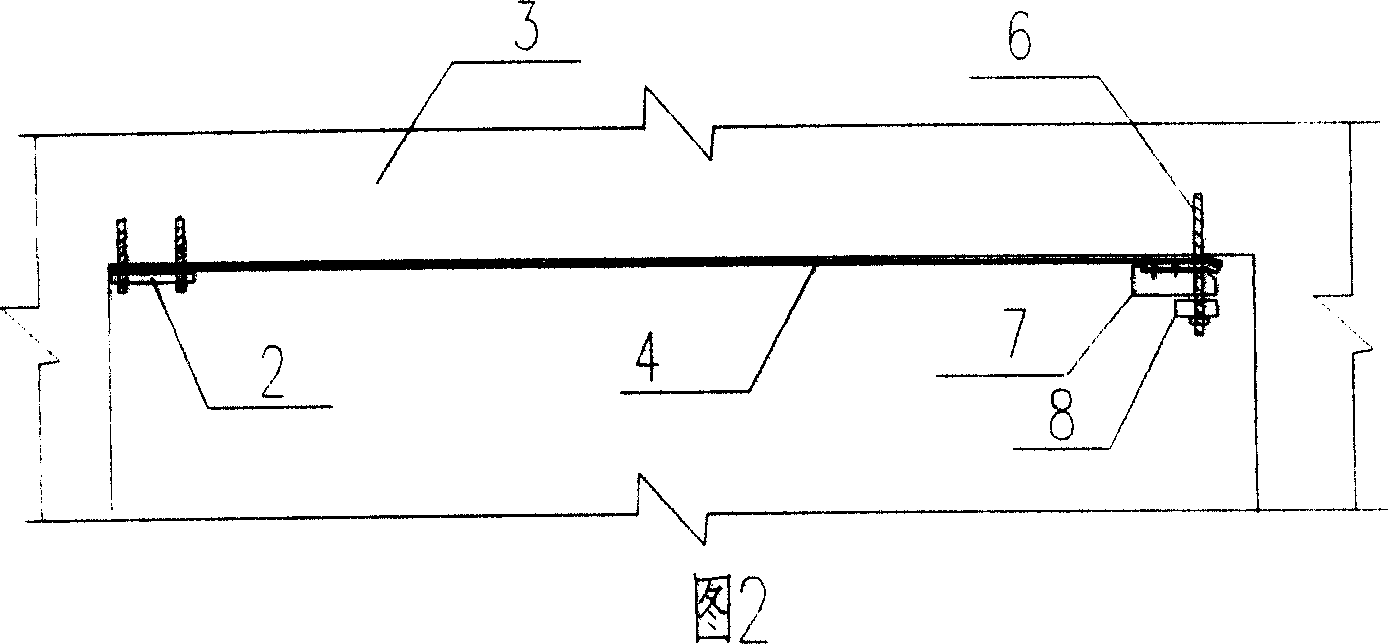

[0026] b. Paste the fixed end and tension end as shown in Figure 1:

[0027] First install the anchor bolt (1) at the fixed end, brush the special glue for carbon fiber cloth on the anchoring area, paste one end of the cut carbon fiber cloth (4) on the component (3), then press the flat anchor plate (2), and tighten the anchor Bolt (1) nut to make it stick firmly and become the anchor end; one side of the special-shaped anchor plate (5) is flat, and the other side can be connected and fixed with the push plate (7). Brush glue on the flat side of the The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com