A kind of prestressed steel wire rope shear reinforcement concrete box girder and reinforcement method thereof

A technology of concrete box girders and steel wire ropes, applied in bridge reinforcement, bridges, bridge materials, etc., can solve the problems of insufficient anchorage length at the end of reinforcement materials, increase the cross-sectional size of original components, and cannot give full play to the strength of materials, etc., to achieve an excellent structure Performance and economic benefits, avoiding stress hysteresis effects, improving the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

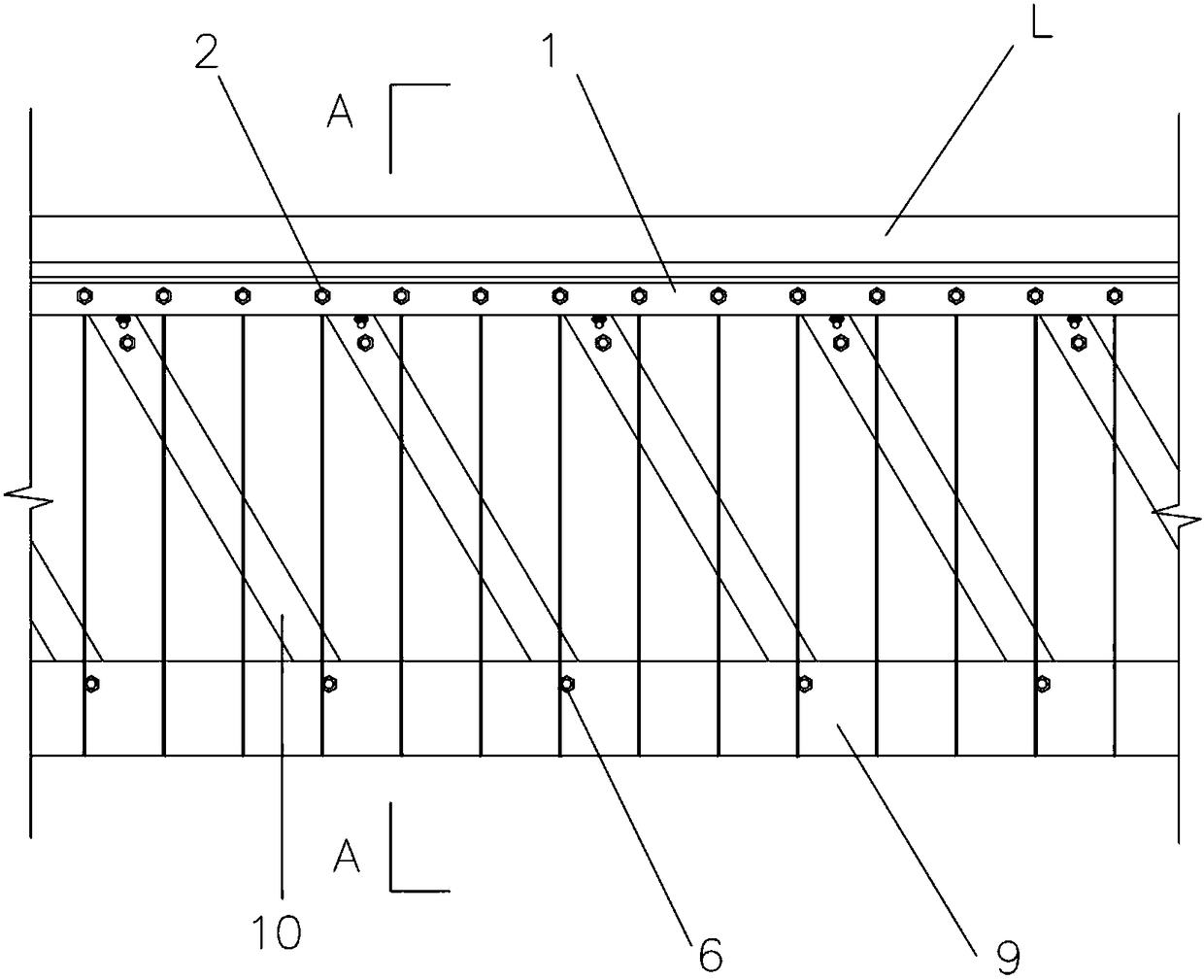

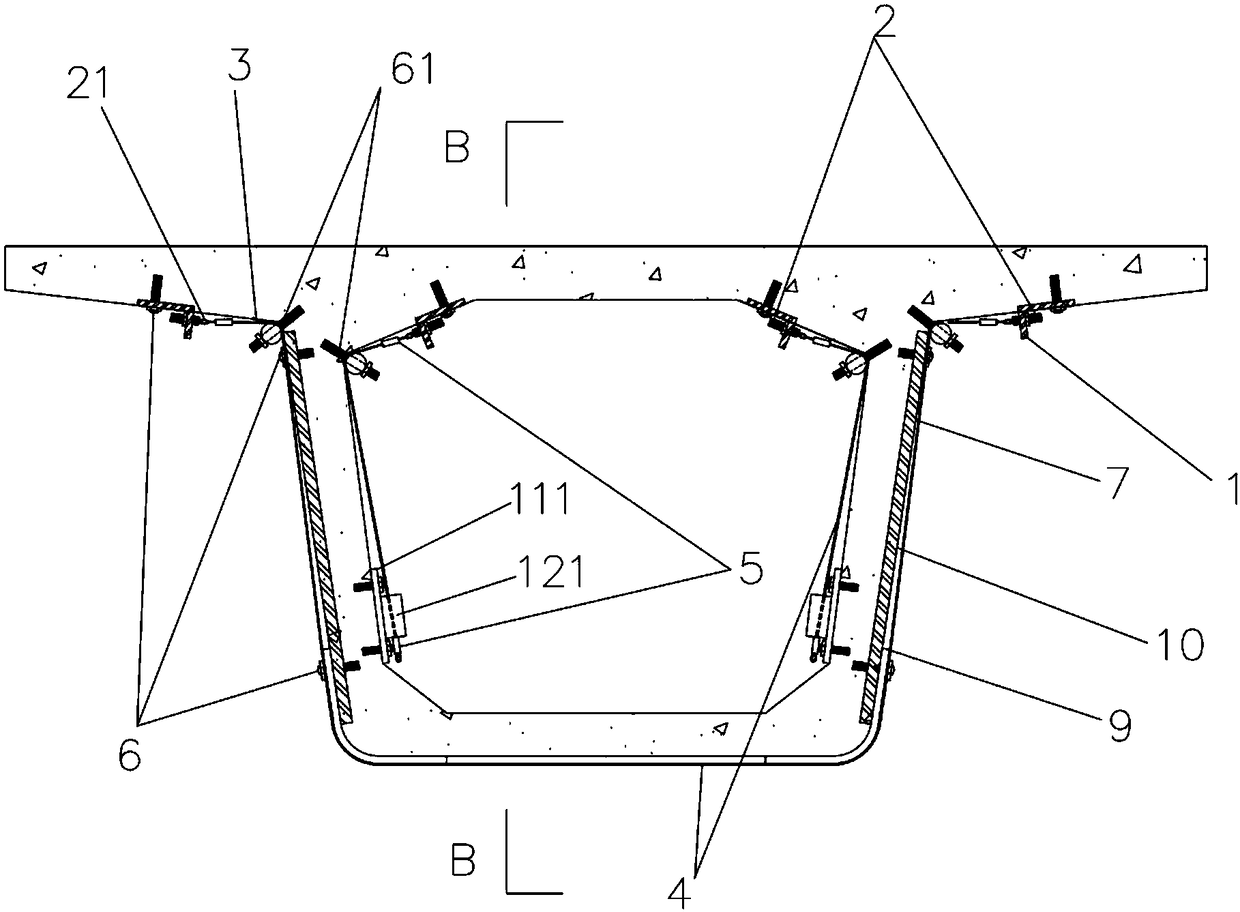

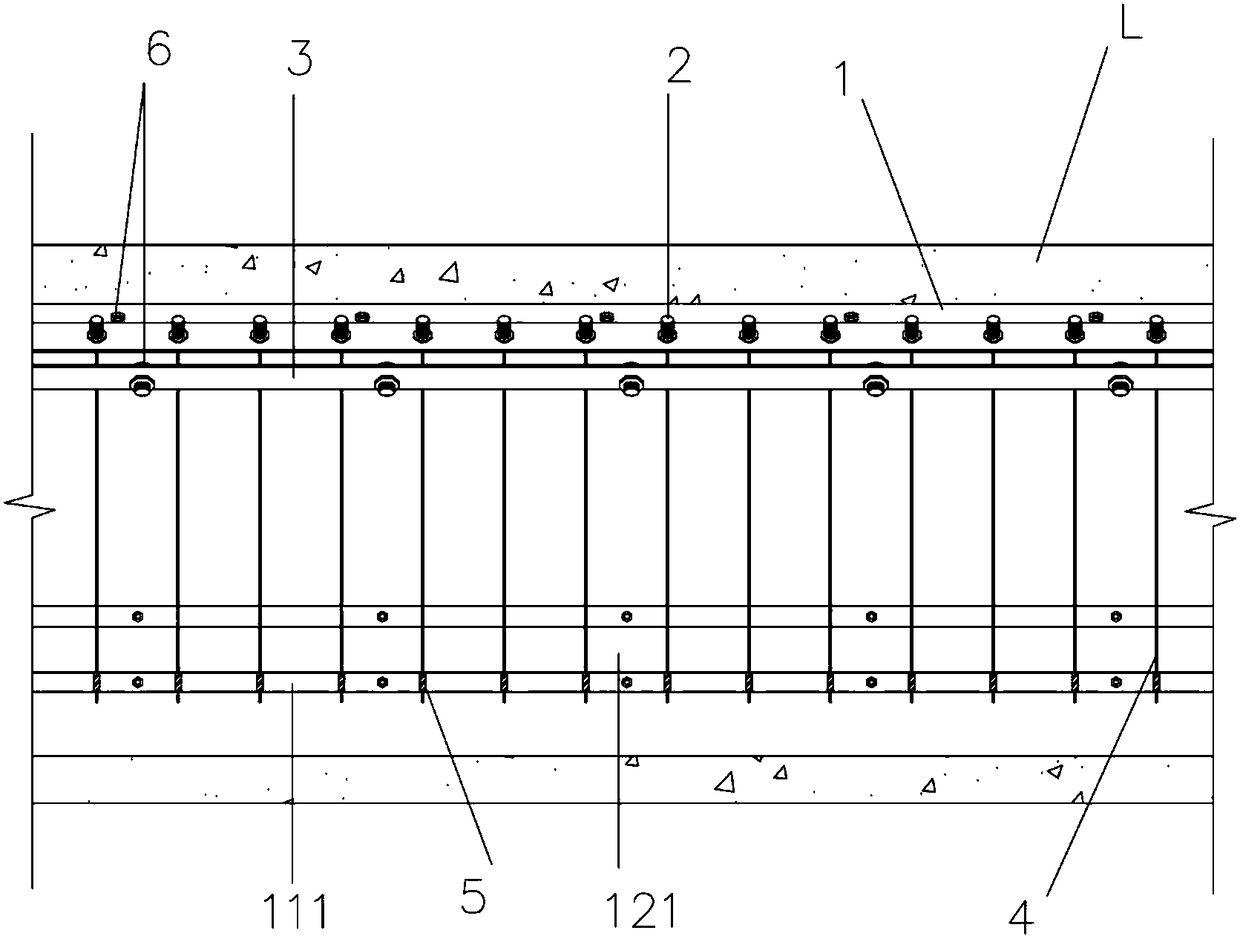

[0039] Such as Figure 1 to Figure 3As shown, a prestressed steel wire rope shear reinforced concrete box girder includes a reinforcement system. The reinforcement system includes several steel strips, each steel strip is obliquely embedded and anchored on both sides of the box girder web; it also includes four angle steels 1, four The angle steel 1 is horizontally fixed on the bottom of the left and right wing plates of the box girder and the bottom of the inner roof plate through one of the respective sides, and a row of bolt holes are respectively opened on the other side along its length direction, and several adjustable bolts 2 are locked and arranged one by one. In the bolt holes of each angle steel 1; on the outside of the web of the concrete box girder, the steel wire rope 4 is tensioned around the bottom of the beam and both ends pass through the ring 21 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com