A self-stressed concrete composite column confined by frp tubes

A concrete and self-stressing technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of aggravation, complicated construction and restrictions, and achieve the effect of avoiding stress lag, improving mechanical properties, and compacting concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] Such as figure 1 As shown, a FRP tube-confined self-stressing concrete composite column includes an external FRP tube 1 and an internal self-stressing concrete 2, and the FRP tube 1 wraps the self-stressing concrete 2, and the expansion of the concrete and the constraint of the FRP are in the FRP Self-stress is generated in the pipe and concrete, the section of the FRP pipe-constrained self-stressed concrete composite column is selected from one of circular, rectangular or square, and the FRP pipe 1 is selected from glass fiber reinforced plastic pipe, carbon fiber reinforced plastic pipe Or one of the aramid fiber reinforced plastic pipes.

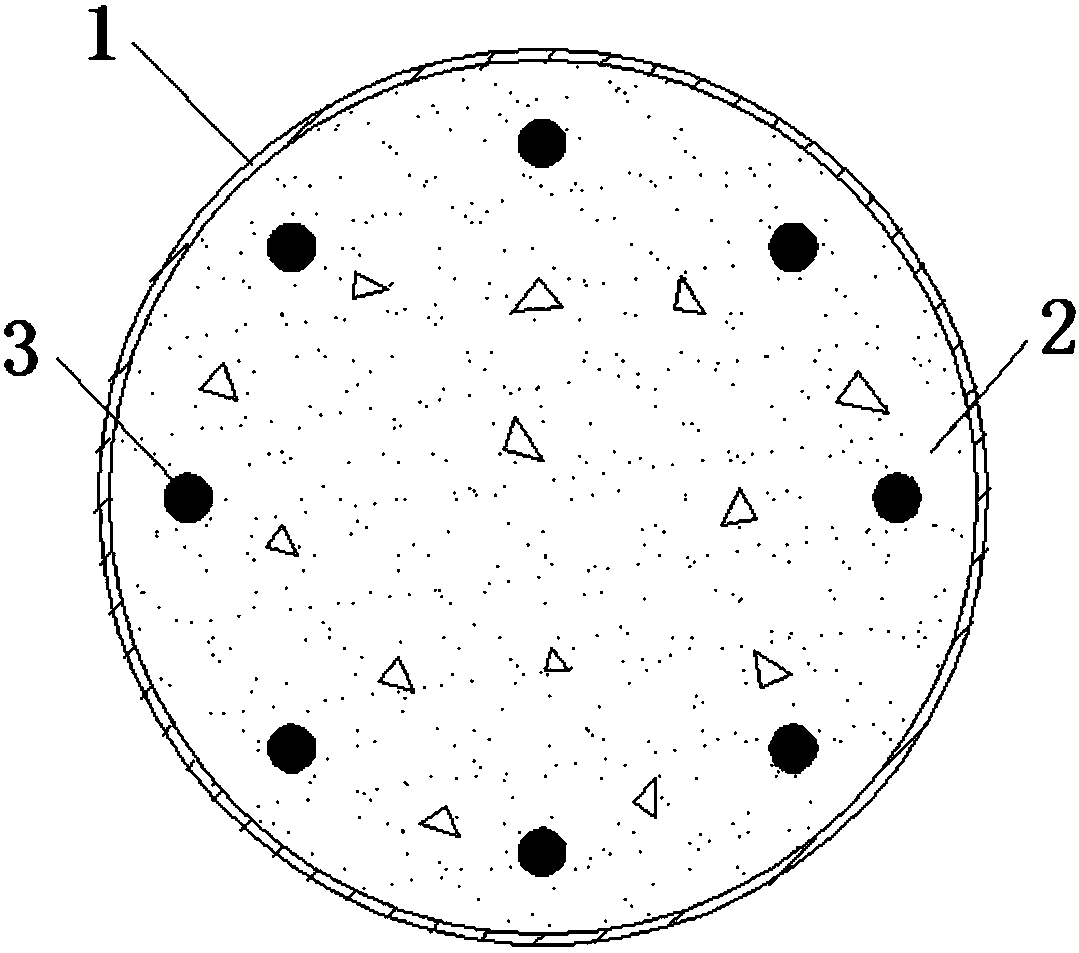

[0019] Such as figure 2 As shown, this is a schematic cross-sectional view of the present invention with steel bars. Evenly distributed steel bars 3 are placed around the self-stressing concrete 2 and run through the top to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com